Hydraulic control valve for a longitudinally adjustable connecting rod with an end-face control piston

a technology of hydraulic control valve and connecting rod, which is applied in the direction of valve operating means/release devices, machines/engines, mechanical equipment, etc., can solve the problems of unintentional spontaneous ignition of the piston engine, component damage in the engine, and the spark ignition engine not running smoothly, so as to reduce the installation space required for the control valve, increase the operational reliability, and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

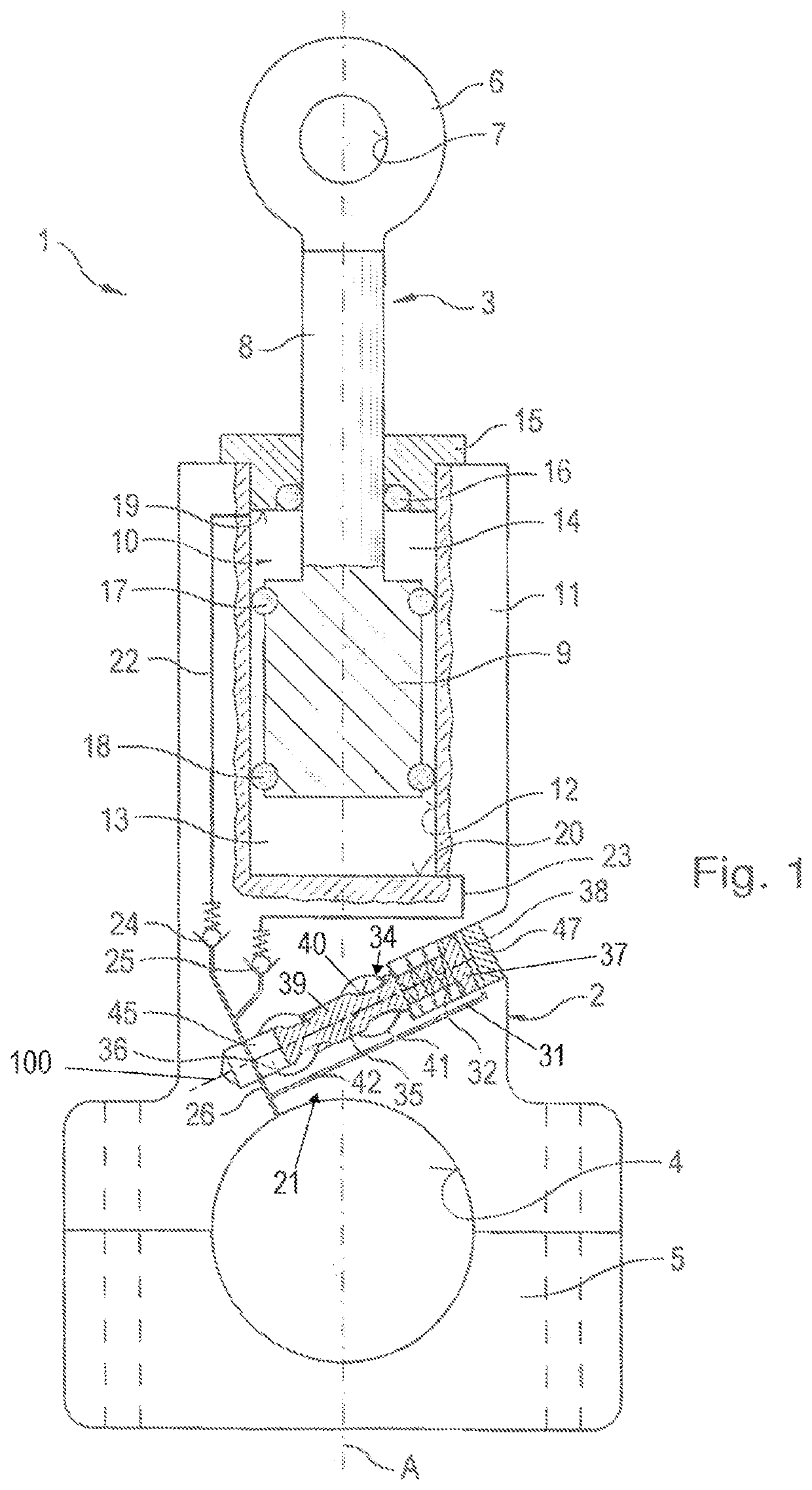

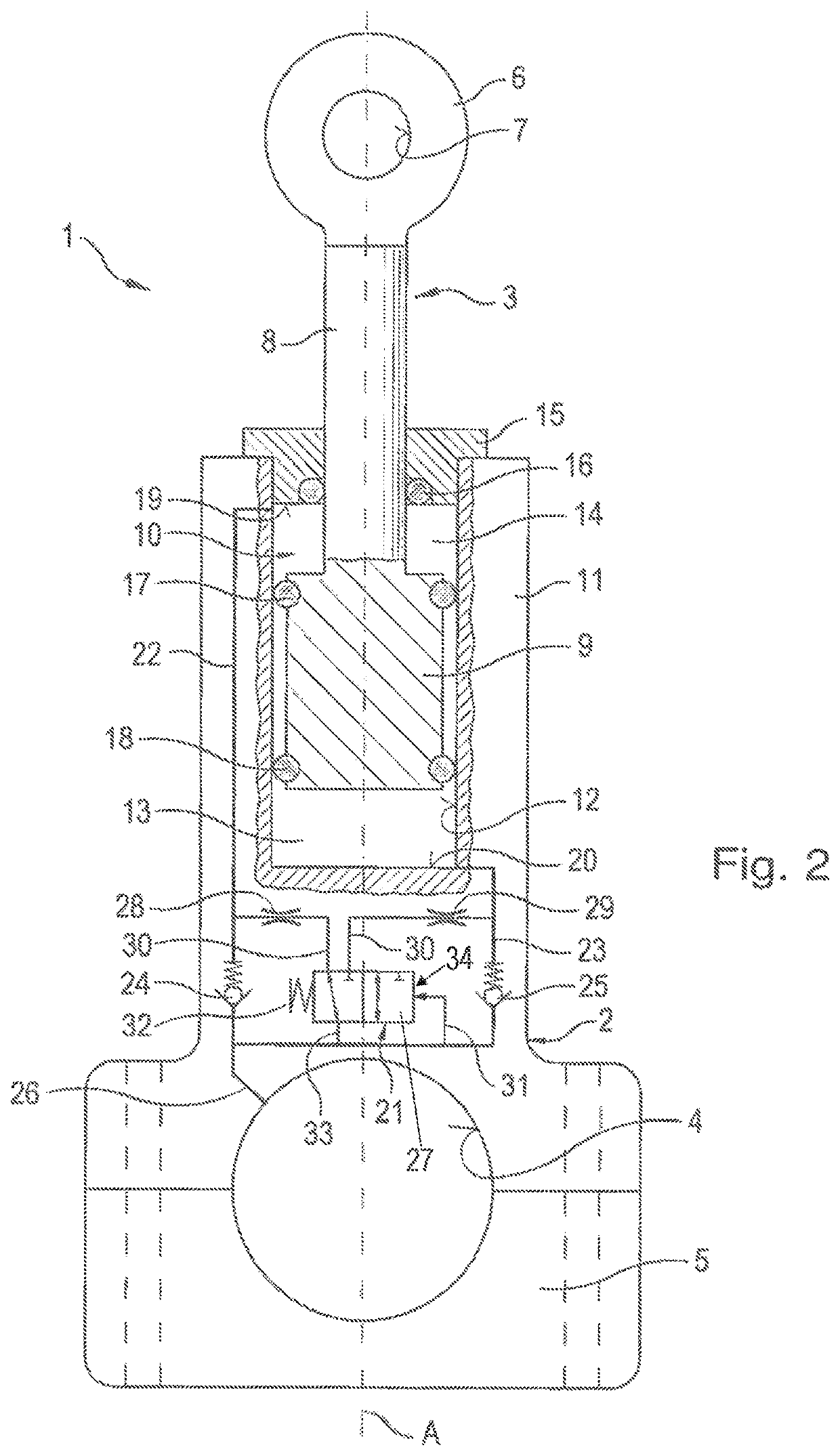

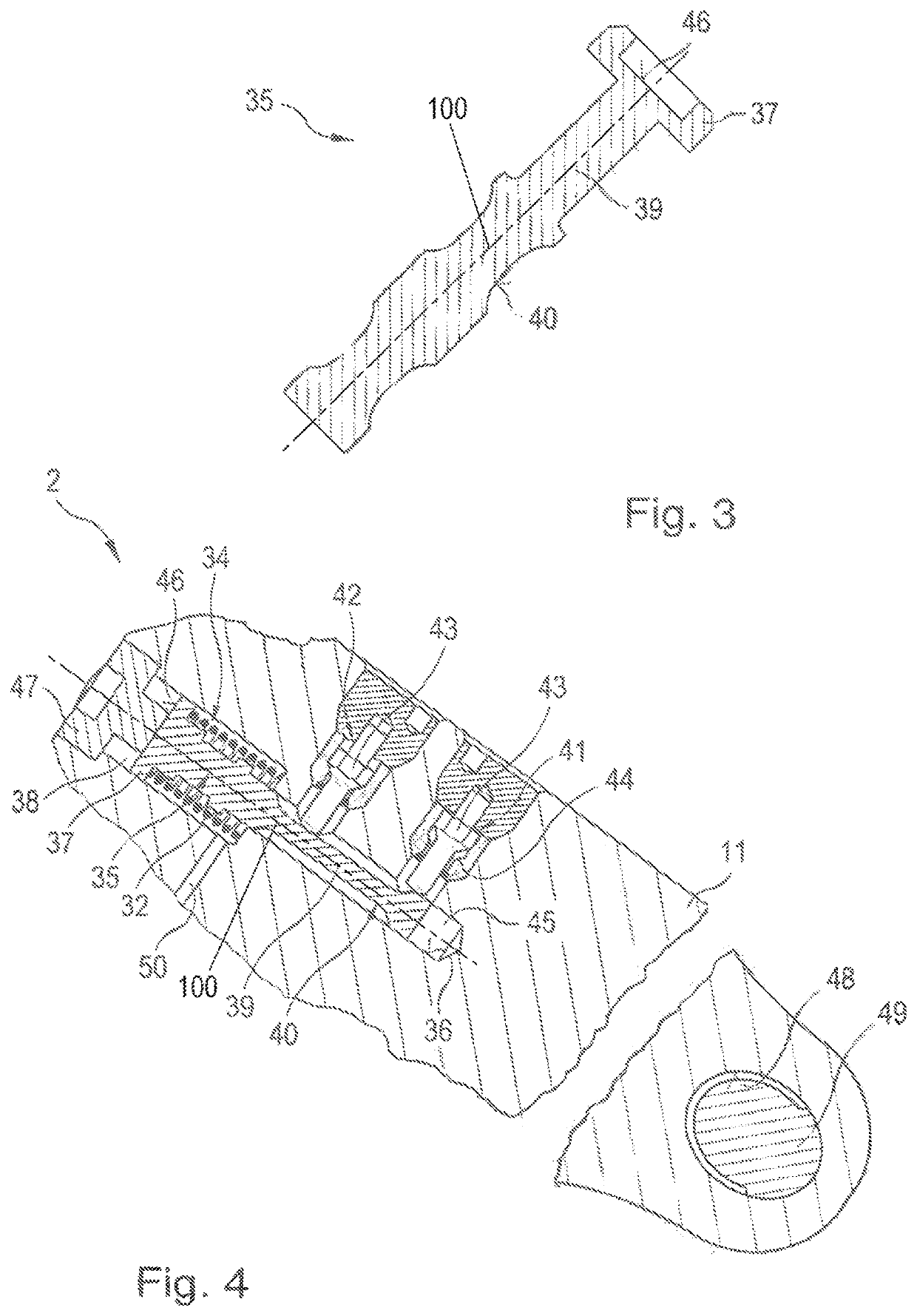

[0029]Longitudinally adjustable connecting rod 1 shown in the schematic view in FIG. 1 comprises two connecting rod members 2, 3 telescopically movable relative to one another. Lower connecting rod member 2, which is arranged at the bottom in the illustration of longitudinally adjustable connecting rod 1 in FIG. 1, comprises a connecting rod large end 4 with which longitudinally adjustable connecting rod 1 is mounted on the crankshaft (not shown) of the piston engine. For this purpose, a bearing shell 5 is further arranged on lower connecting rod member 2 and together with the lower region of lower connecting rod 2, which is also configured like a bearing shell, forms connecting rod large end 4. Bearing shell 5 and lower connecting rod member 2 are connected to one another by way of connecting rod screws (shown schematically as dashed lines). Upper connecting rod member 3 comprises a connecting rod head 6 with a connecting rod small end 7 which receives the piston pin (not shown) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com