Method and device for optical examination of transparent bodies

a transparent body and optical examination technology, applied in the field of methods and devices for optical examination of bodies, can solve the problems of inability to distinguish, deformation of optical systems, and inability to distinguish whether an adhering lint is located on the body, and achieves the effect of simple setup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088]In the following detailed description of preferred embodiments, the same reference numerals designate substantially similar components in or on these embodiments, for the sake of clarity. However, for a better understanding of the invention, the preferred embodiments illustrated in the figures are not always drawn to scale.

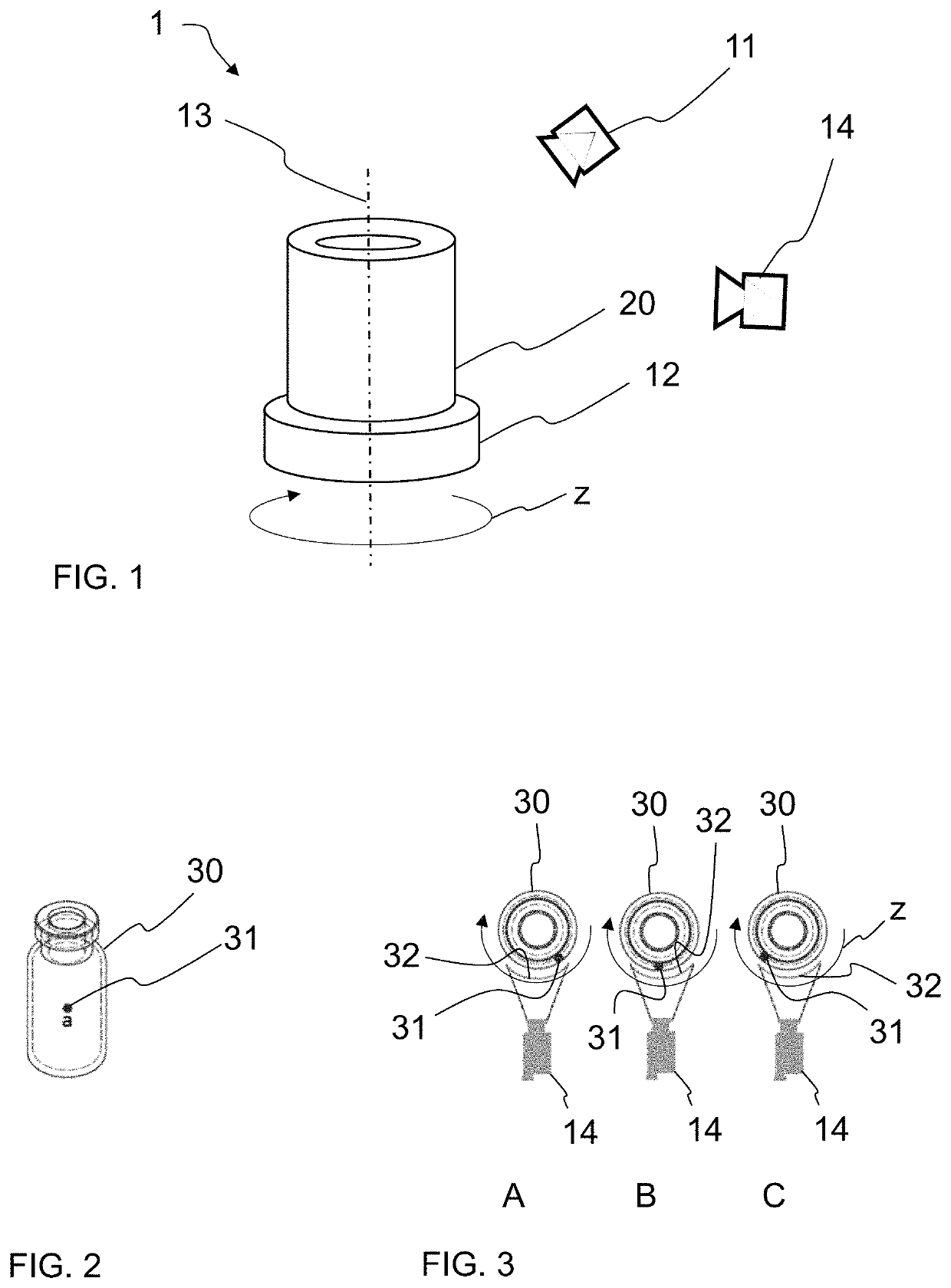

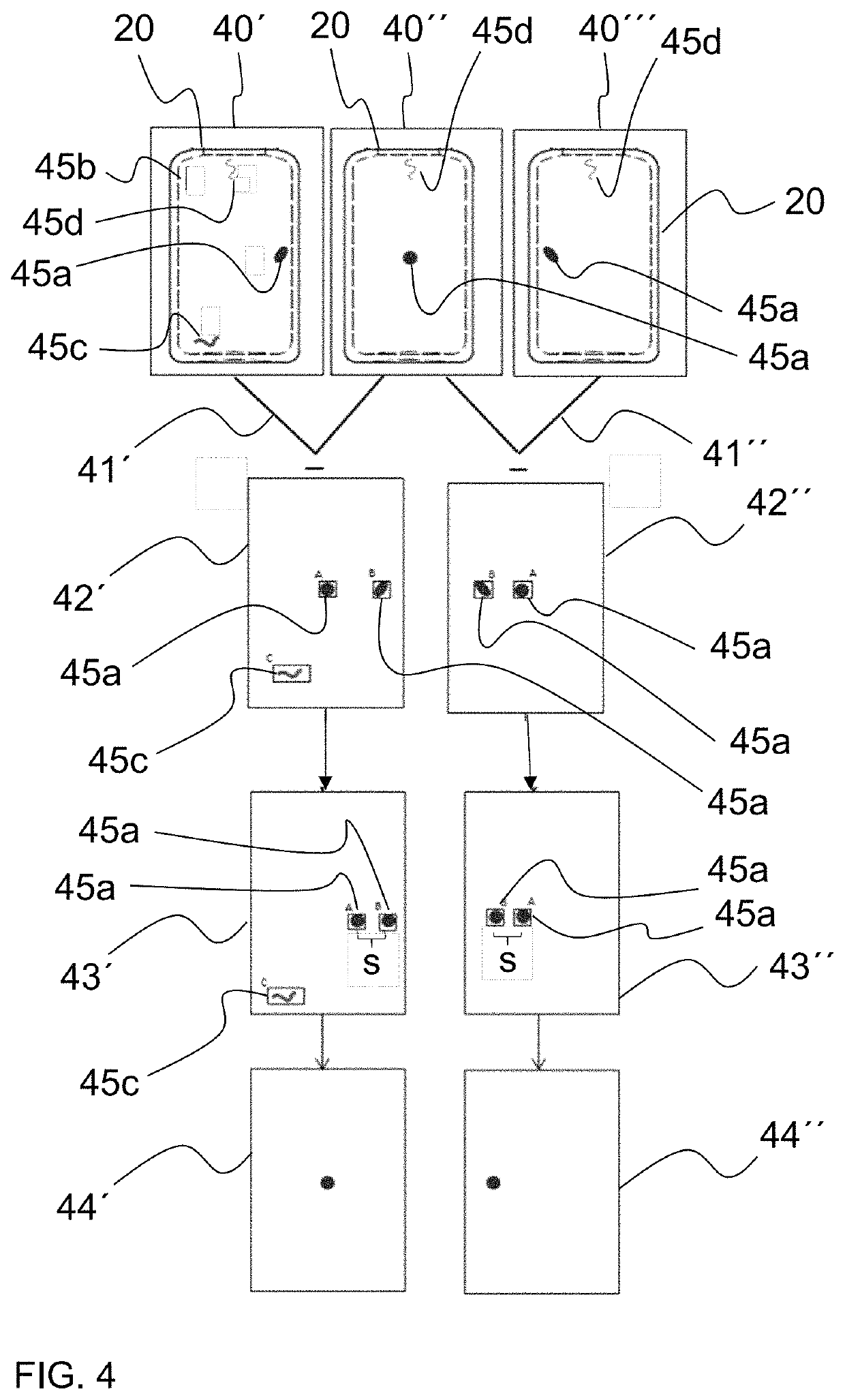

[0089]FIG. 1 schematically shows a portion of an inspection device designated by reference numeral 1 as a whole, for optical examination and inspection of bodies.

[0090]The invention provides an inspection method and an inspection device for quality control of transparent bodies which preferably have a rotationally symmetrical shape. It is particularly useful for the examination of transparent bodies made of plastic, glass, or glass ceramics, which may be solid as well as hollow.

[0091]Preferably, these may be pharmaceutical containers or packaging means, such as glass syringes or glass ampoules. During the inspection, the body to be examined is rotated about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth of focus | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| depth of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com