Re-injection method for produced-water desorption oxygen-removal mixing polymer for improving petroleum recovery efficiency

A technology for preparing polymers and desorption, applied in drilling compositions, chemical instruments and methods, and production fluids, etc., can solve the problems of long process flow, expensive filters, and repeated cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

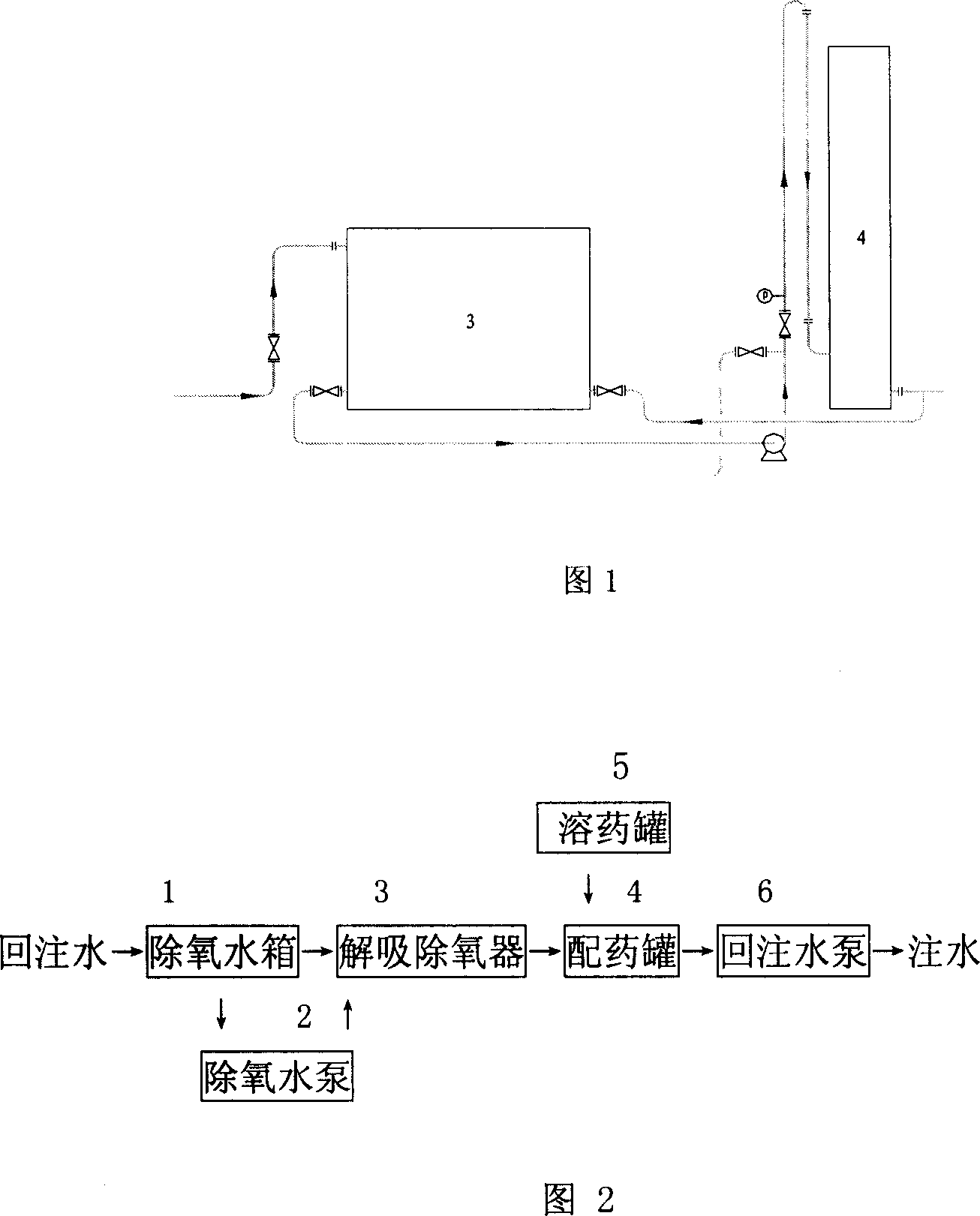

Method used

Image

Examples

Embodiment 1

[0028] Deoxygenation test after reinjection of water for oxygenation

[0029] In order to test the deoxygenation capacity of the reinjection water desorption deoxygenation device, the reinjection water from the oilfield was taken to carry out the deoxygenation experiment after oxygenation. Under the normal operating conditions of the oxygen removal system, multiple samples of tests and inspections were carried out. The results are shown in Table 1.

[0030] Table 1 Results of desorption and deoxygenation experiments

[0031] sewage index

[0032] The test results show that the DO content in the effluent after low-temperature desorption and oxygen removal treatment of the reinjected water is 0.03-0.10 mg / L, which meets the requirements for DO in sewage polymer injection. The DO content in the effluent water after the reinjection water is deoxidized by the aeration desorption cycle is lower, and generally DO≤0.01mg / L.

Embodiment 2

[0034] Operation test of re-injection water desorption and oxygen removal project

[0035] Under the normal operating conditions of the desorption deoxygenation system, a one-year field test of the deaeration engineering of different reinjection water in the oilfield was carried out, and the results are shown in Table 2.

[0036] Table 2 Statistical results of desorption and oxygen removal treatment with different reinjection water quality (mg / l)

[0037] Water quality project

[0038] It can be seen from Table 2 that the reinjection water has been treated by the low-temperature desorption and oxygen removal process system. The water quality of the reinjection water is 5-10mg / l of suspended solids, pH=7.8-8.9, water temperature of 30-45°C, and oil content of 3-8mg / l. l, COD cr =310~950mg / l, DO=2.8~5.9mg / l, DO<0.1mg / l in the effluent of the deaerator system, and DO meets the requirements of oilfield reinjection water quality indicators.

Embodiment 3

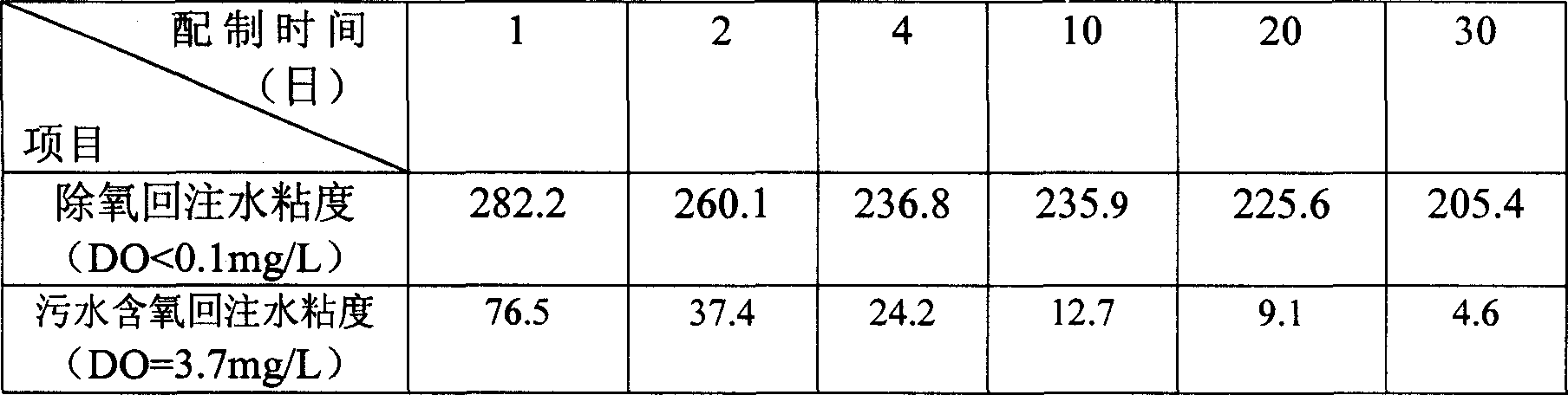

[0040] Effect of Injection Time on Viscosity of Polymer Solution Prepared from Sewage

[0041] 1500mg / L PAM was added to the raw water and the sewage after desorption and deoxygenation treatment to prepare the polymer solution, and the viscosity of the injected liquid was detected at different preparation injection times. The results are listed in Table 3.

[0042] Table 3 The effect of injection time on the viscosity of polymer solution prepared from sewage

[0043] It can be known from Table 3 that the viscosity of the polymer solution prepared by reinjection water without desorption and oxygen removal treatment decreased rapidly with time, and the viscosity of the solution decreased to 76.5 after 1 day, and decreased rapidly with time, and dropped to 12.7 after 10 days, and 12.7 after 20 days. After 30 days, it dropped to 9.1 and 4.6 respectively, and there was almost no effect after reinjection; the viscosity of the polymer solution prepared by reinjection water after deso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com