Lower entry lower exit spiral type conveyer

A conveyor and screw type technology, which is applied in the field of bottom-in and bottom-out screw conveyors, can solve the problems of increasing the installation of conveyors, gear sets with 13 large loads, and reducing the installation space of screw conveyors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

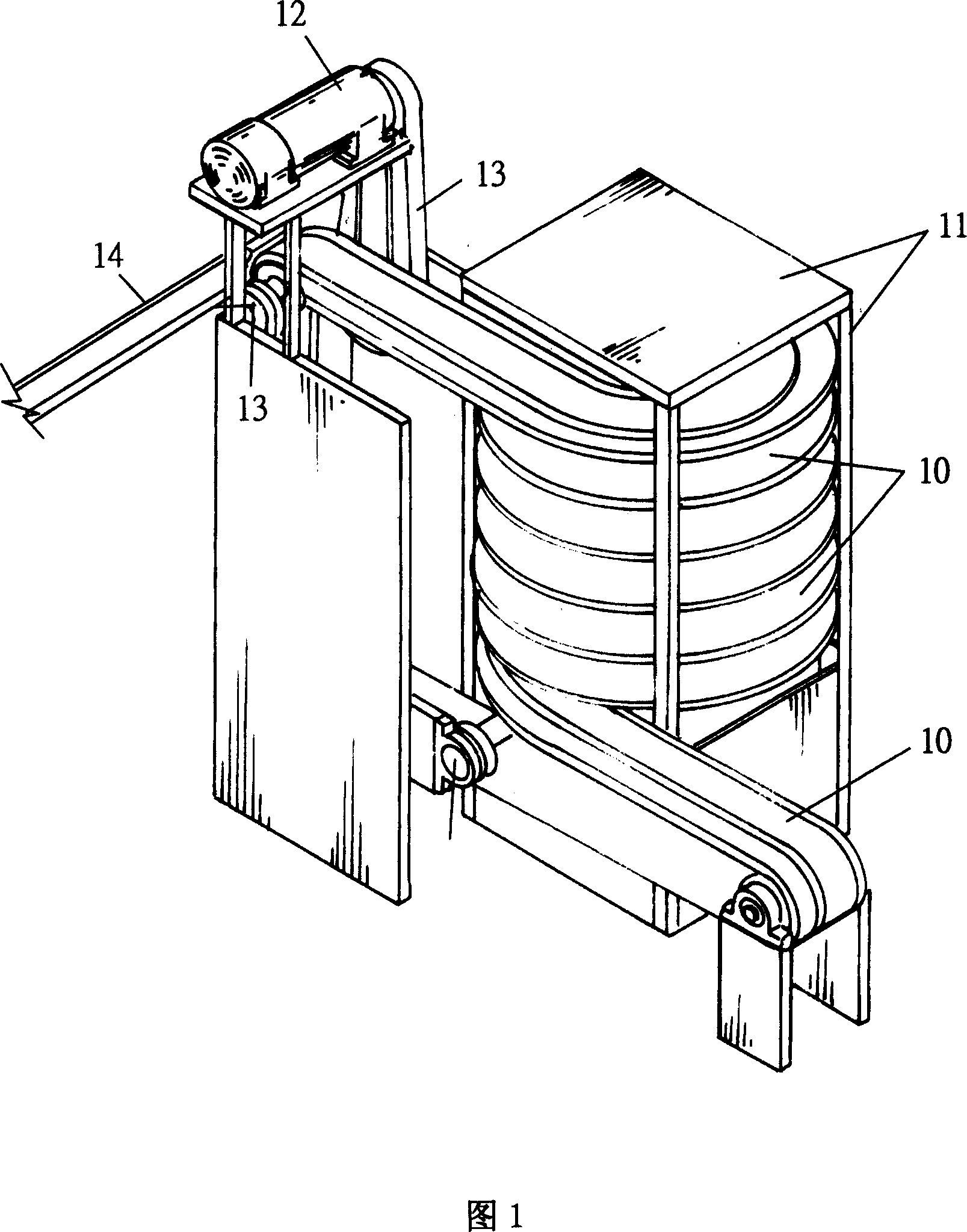

[0024] Relevant technical means and structural feature thereof that the present invention utilizes for reaching the purpose, cooperate the preferred embodiment shown in accompanying drawing again hereby, describe in detail as follows:

[0025] Please refer to Fig. 2, the present invention mainly comprises skeleton body 20, conveyer belt 30, transmission machine 40 and auxiliary transmission device 50 and constitutes; Wherein:

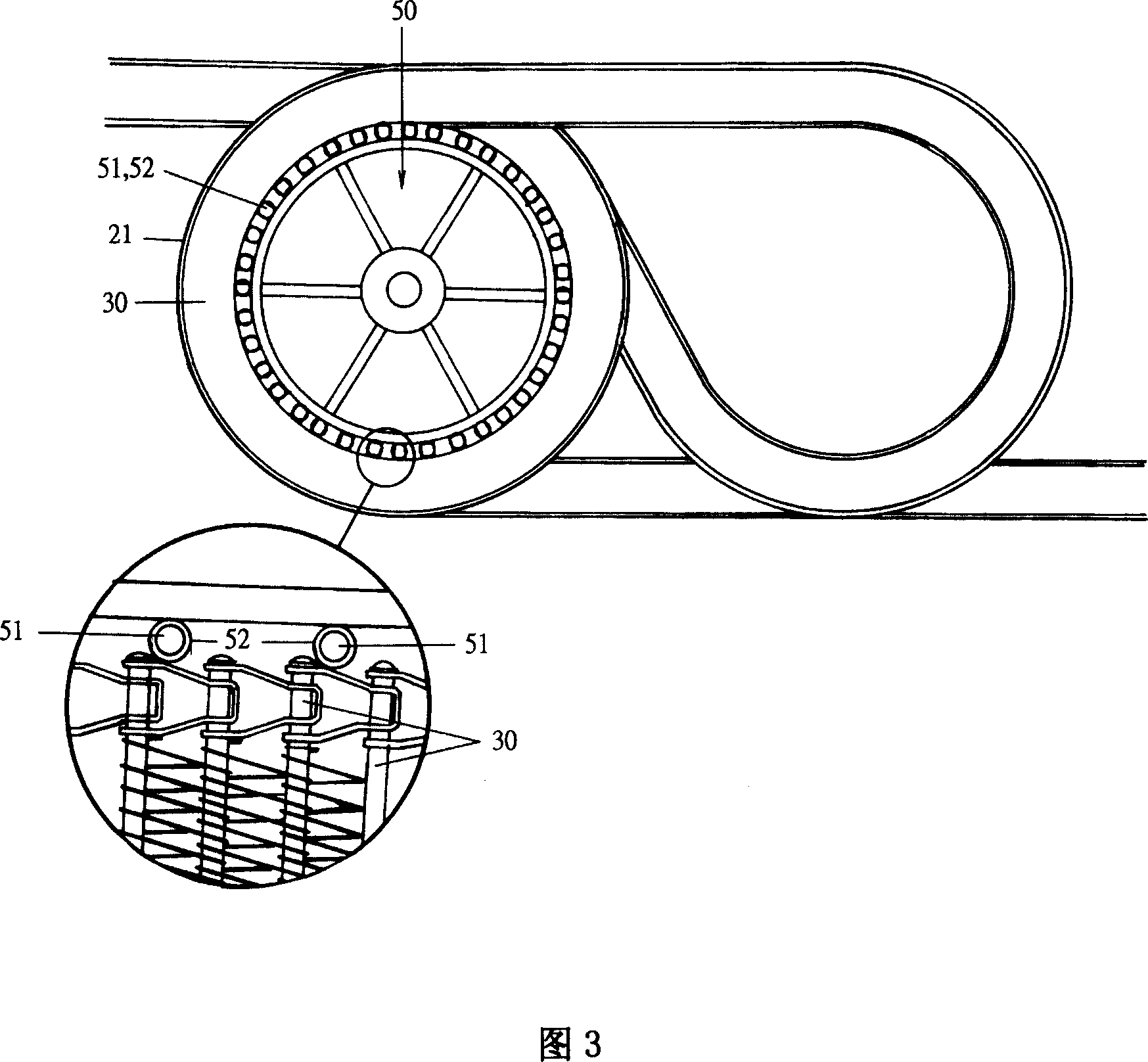

[0026] Please refer to Figures 3 and 4 again, the skeleton body 20 is a frame made of metal skeleton, in which a spiral orbit 21 is erected, and the orbiting method is to start from the bottom, go up to the top, and then criss-cross. The way goes down to the end point, the track 21 can be used for the conveyor belt 30 to bear on it, and then the transmission 40 drives the gear set 41 to make the conveyor belt 30 move on the track 21; please refer to Figures 5 and 6, the The auxiliary transmission device 50 is arranged upright by several brackets 51 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com