Method and device for carrying out a thermodynamic cyclic process

一种热力学循环、压力的技术,应用在蒸汽机装置、机器/发动机、机械设备等方向,能够解决缺少经济性、无有吸引力等问题,达到简化管道铺设的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

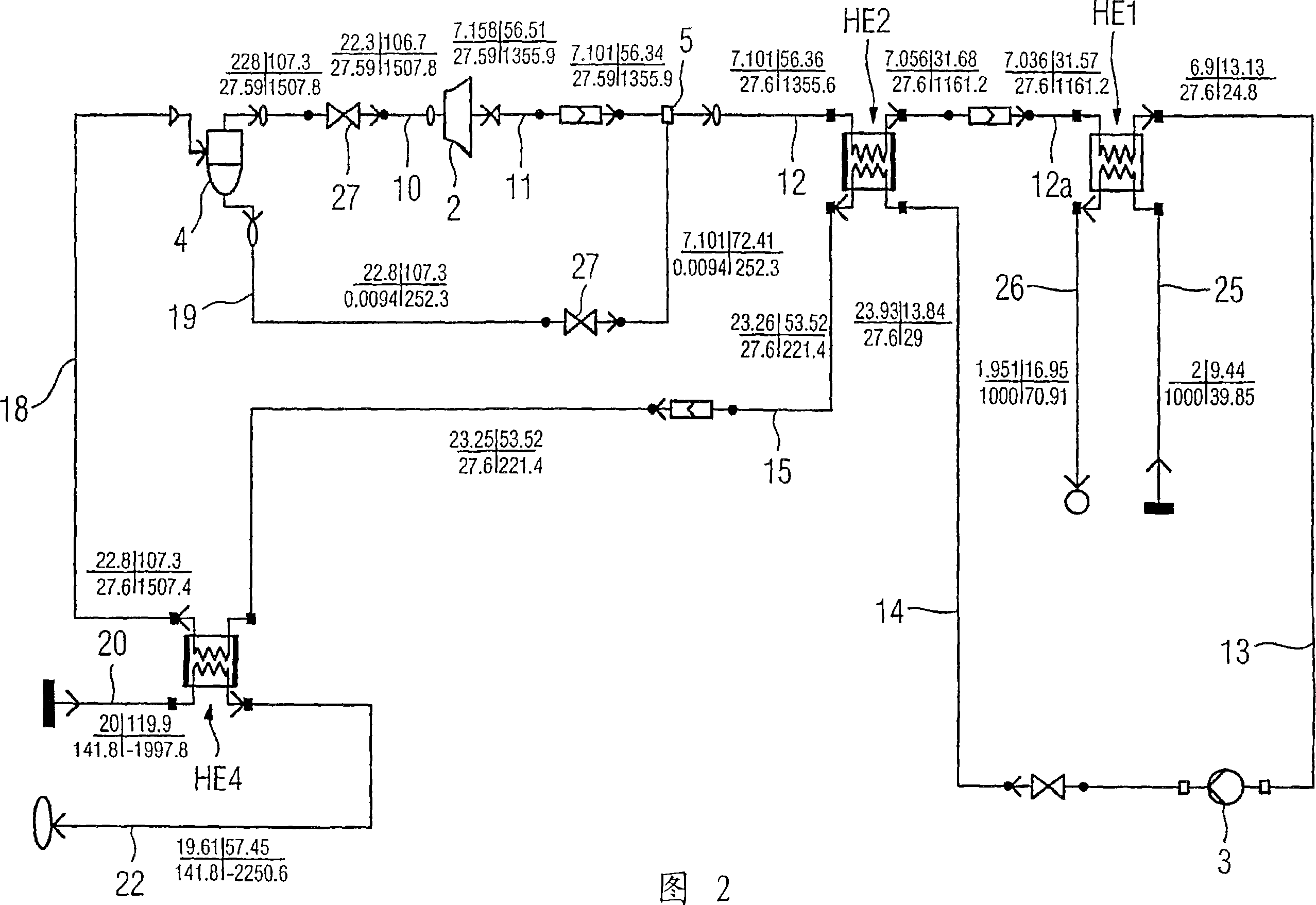

[0022] The device 1 shown in FIG. 1 for carrying out a thermodynamic cycle has a (recovery) heat exchanger HE4 through which on the primary side hot water 20 of a geothermal source not described in detail flows through and on the secondary side It is connected on the one hand to the heat exchanger HE2 and on the other hand to the separator 4 . The separator 4 serves to separate the vapor phase from the liquid phase of a partially vaporized working medium. A steam side outlet of the separator 4 is connected to a turbine 2 . The turbine 2 is connected on the outlet side to a mixer 5 which is also connected to a liquid outlet of the separator 4 . The mixer 5 is connected on the outlet side to the secondary side of a (recovery) heat exchanger HE2 which in turn is connected to the primary side of a condenser HE1 through which cold water flows through the secondary side. At its primary-side outlet, the condenser HE1 is connected via a pump 3 to the primary side of the heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com