Working machine

A working machine and function technology, applied in mechanical equipment, motor vehicles, earth movers/shovels, etc., can solve problems such as open circuits that cannot be applied to return fluids and return to the box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

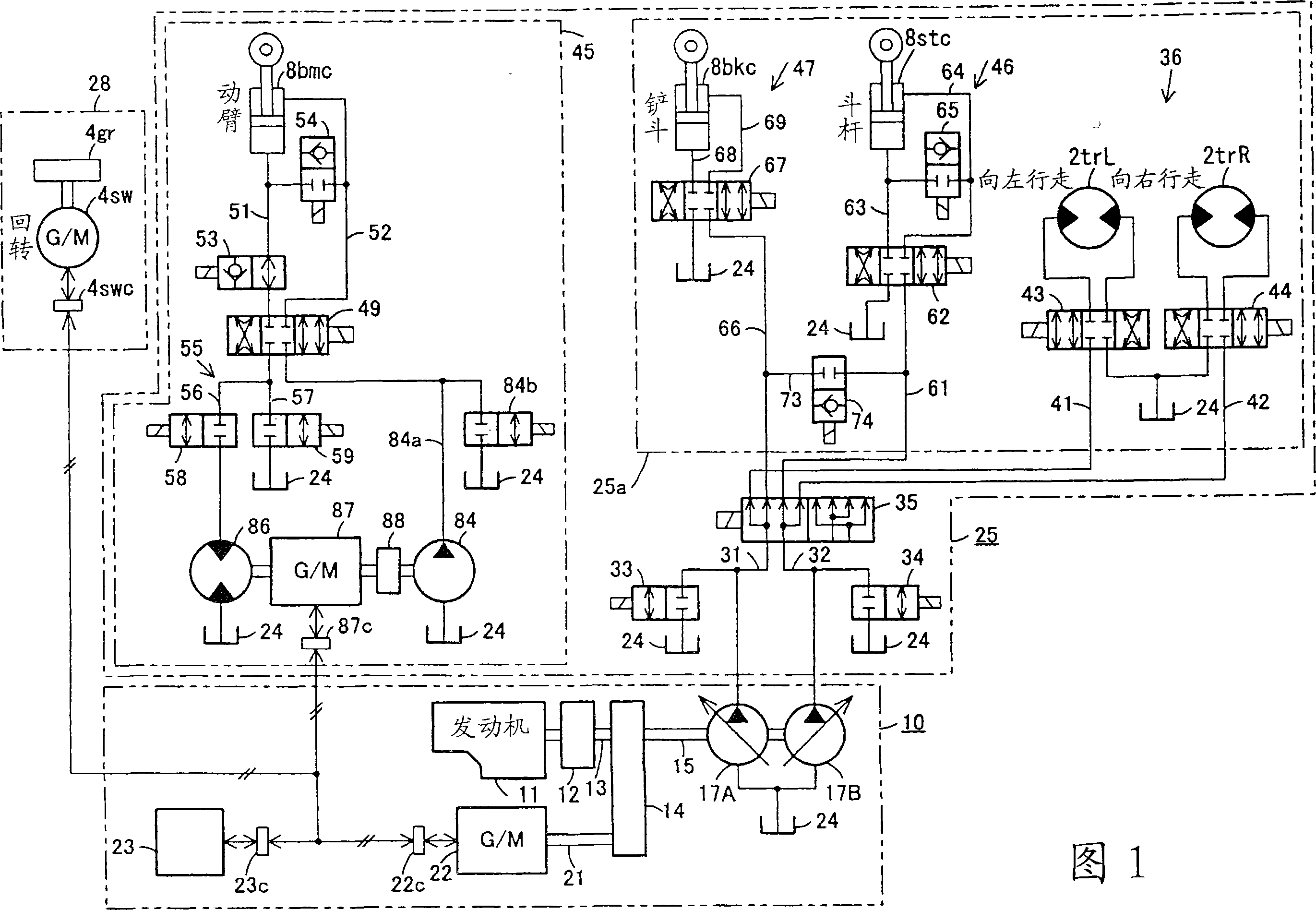

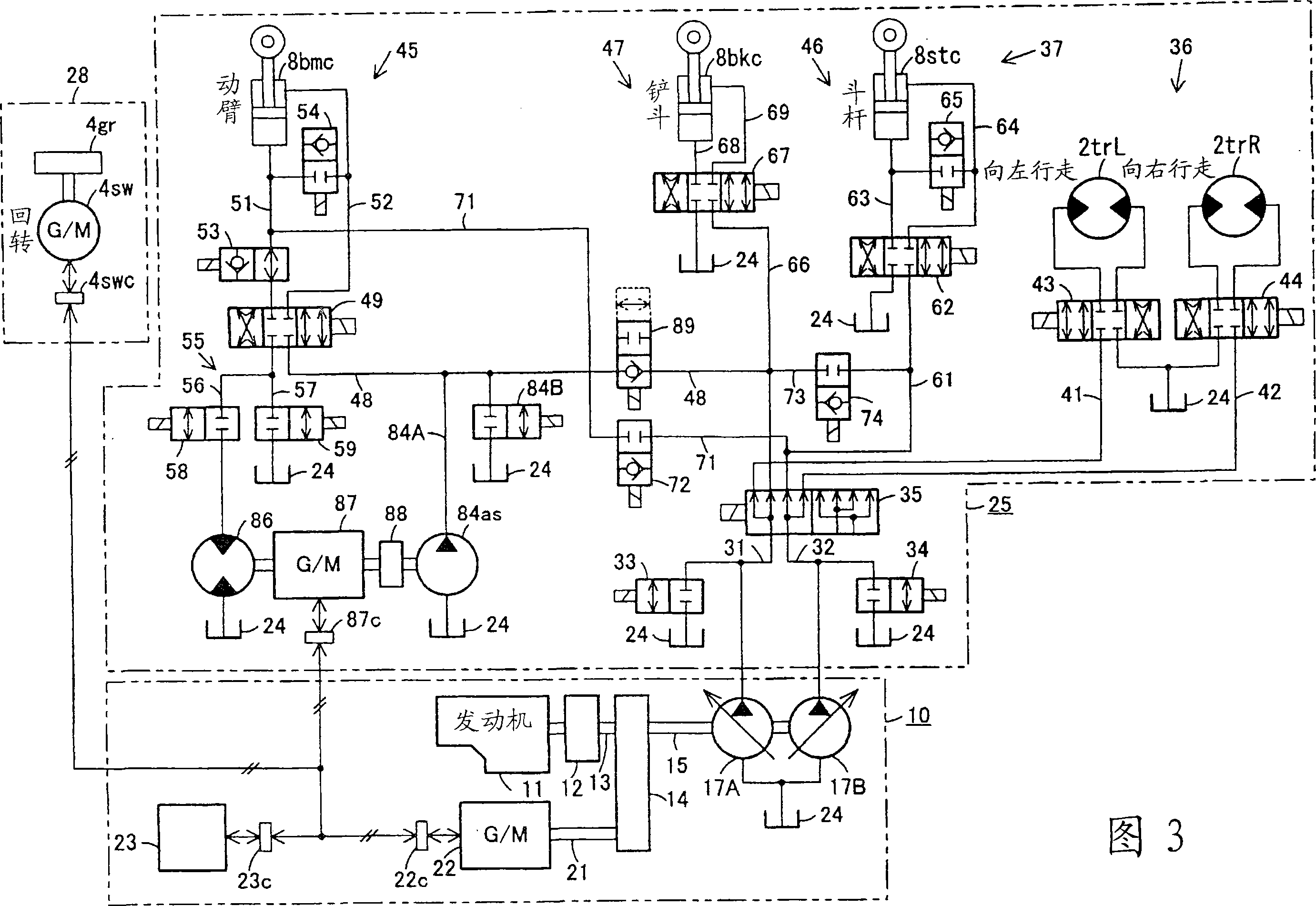

[0028] Hereinafter, the present invention will be specifically described with reference to one embodiment shown in FIGS. 1 and 2 and another embodiment shown in FIG. 3 . In addition, fluid and fluid pressure use working oil and oil pressure.

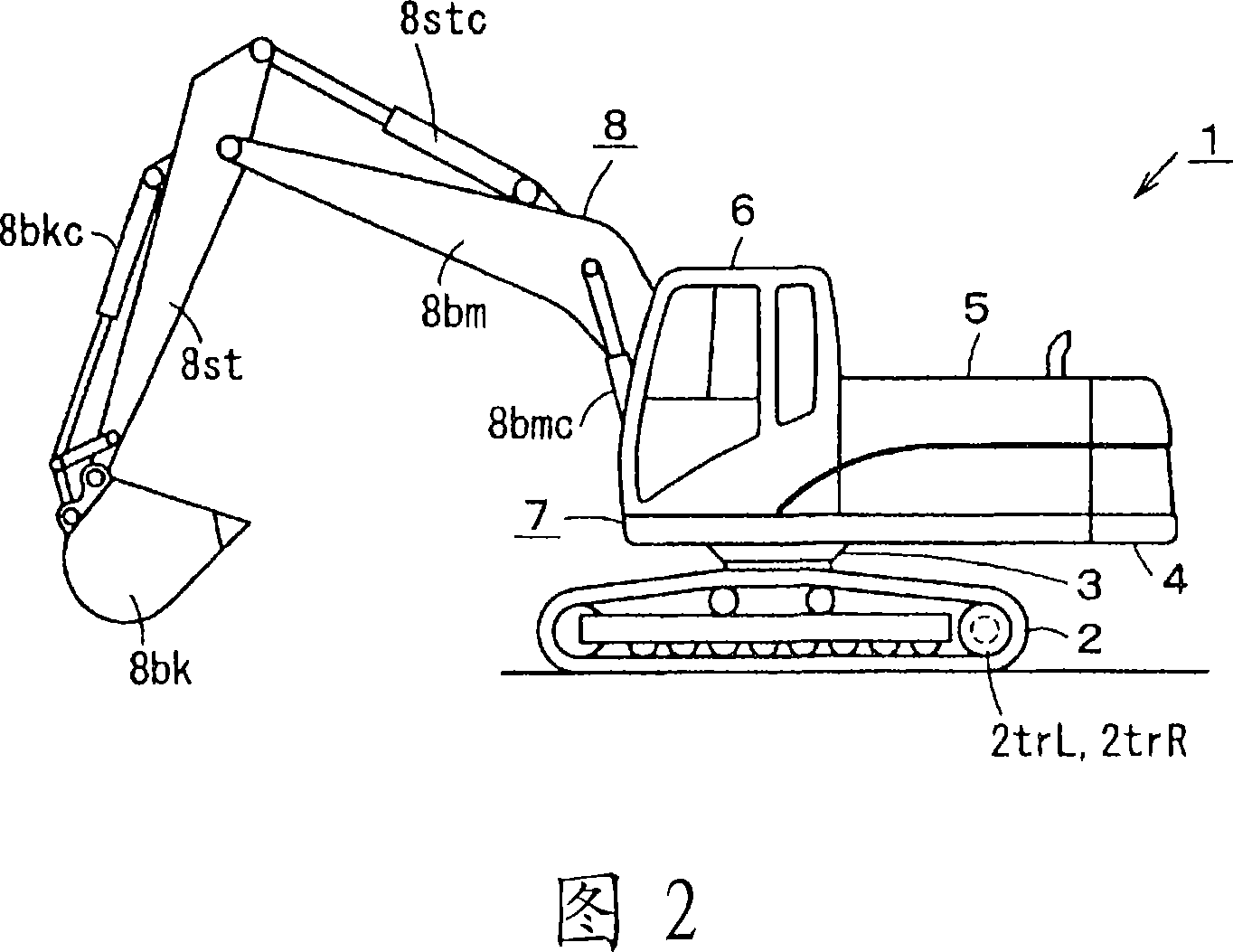

[0029] First, an embodiment shown in FIG. 1 and FIG. 2 will be described. As shown in FIG. 2 , the working machine 1 is a hydraulic excavator, and an upper slewing bearing 3 is freely rotatable on the lower traveling body 2 . A body 4, on which a power unit 5 such as an engine and a fluid pressure pump, a cab 6 for protecting an operator, and the like are mounted, thereby forming a machine body 7. The lower traveling body 2 has traveling motors 2trL, 2trR driving the left and right crawler belts respectively, and the upper rotating body 4 has a turning motor / generator (not shown in FIG. ).

[0030] A working device 8 is attached to the upper revolving body 4 . The working device 8 is sequentially rotatably connected to a bracket (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com