Heat pipe performance checkout gear

A detection device and heat pipe technology, applied in heat exchange simulation, heat exchange equipment, material thermal development, etc., can solve problems such as heat loss, temperature measurement variation, heat pipe performance variation, unfavorable heat pipes, etc., and achieve good consistency effect with reproducibility, good consistency, avoidance of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

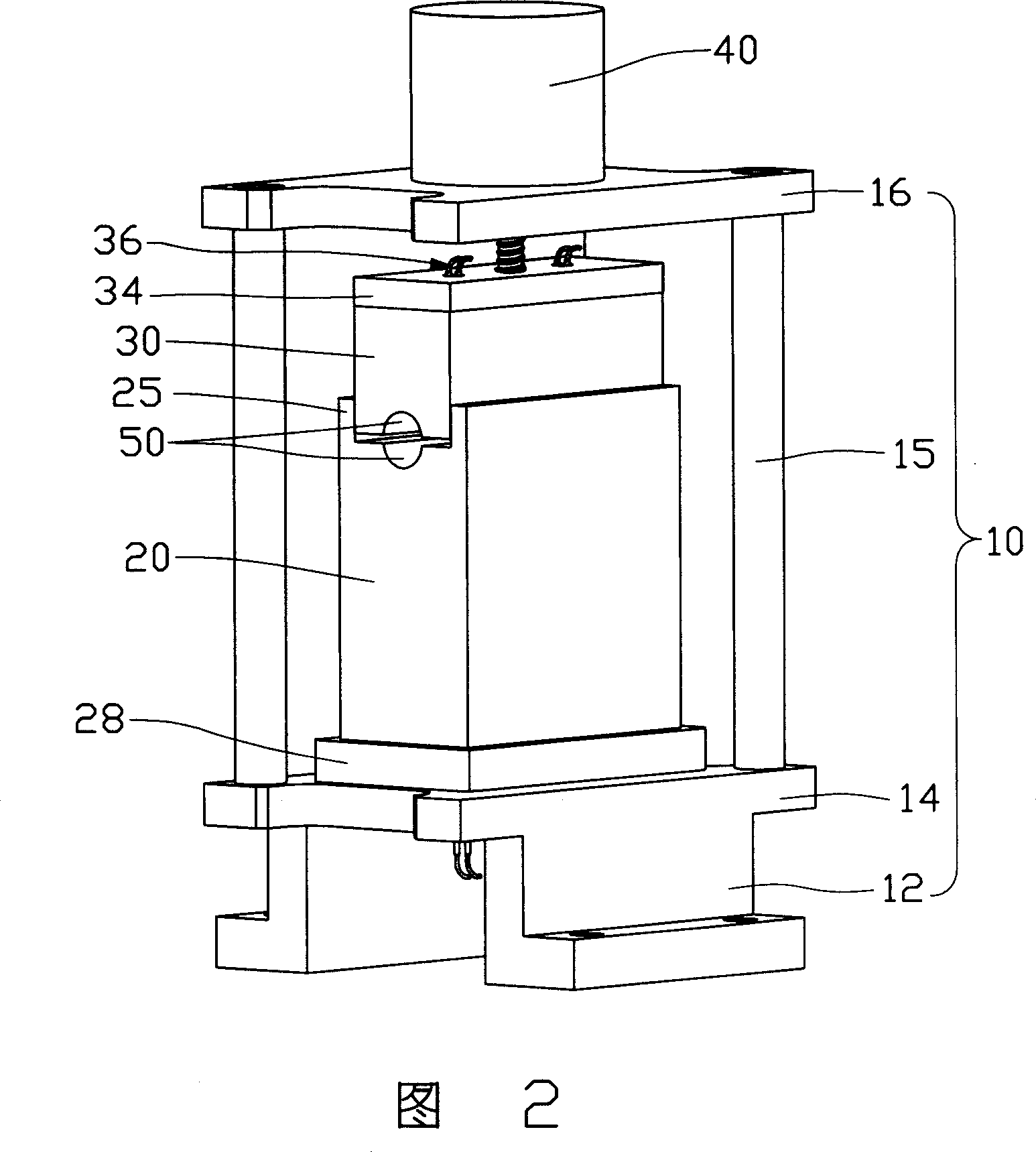

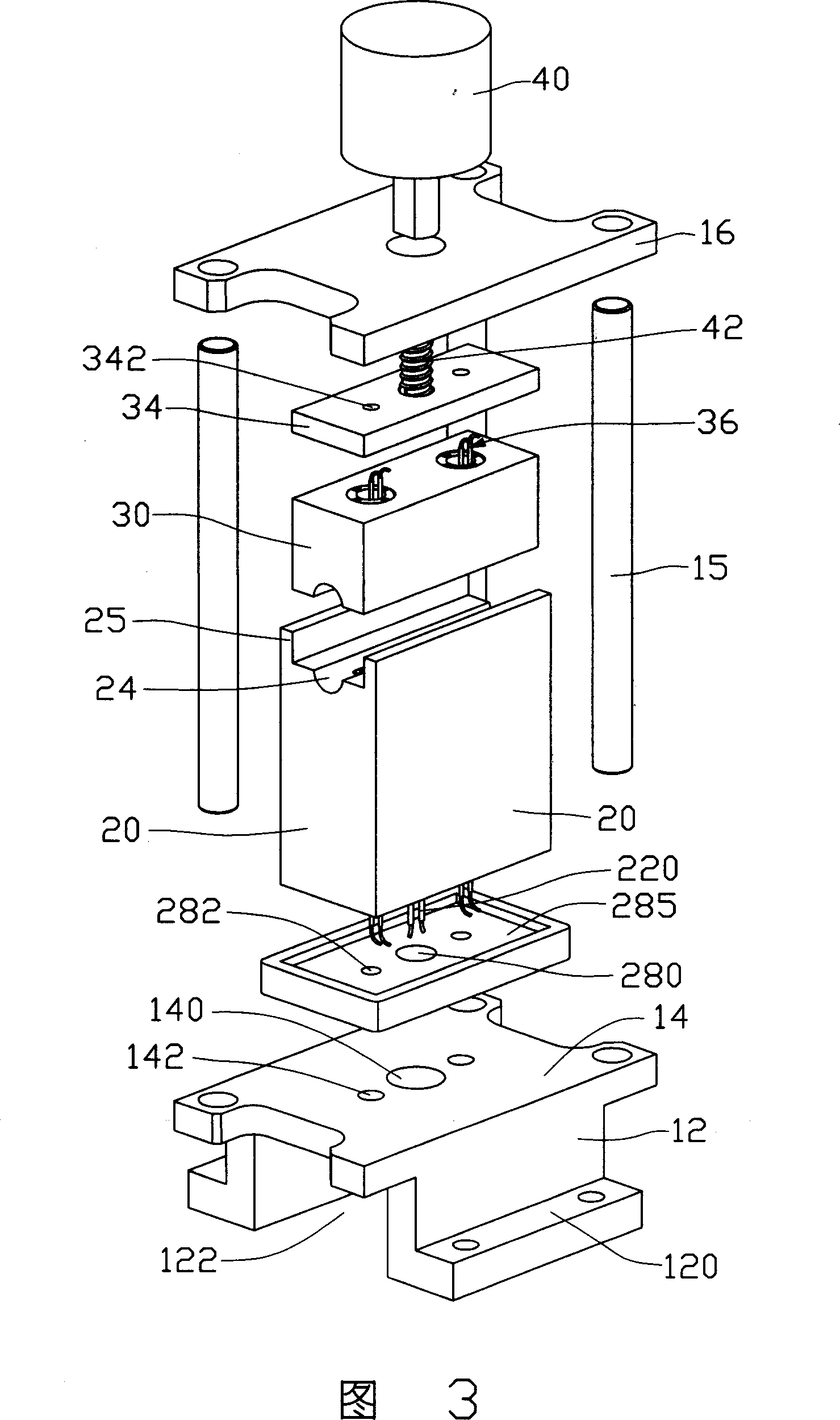

[0022] The heat pipe performance detection device of the present invention will be further described below with reference to FIGS. 2 to 6 .

[0023] Fig. 2 is a perspective view of the appearance of the first embodiment of the heat pipe performance testing device of the present invention, Fig. 3 is a perspective exploded view of Fig. 2, Fig. 4A is a perspective exploded view of the fixing part and the heat insulating bottom plate in Fig. 3, and Fig. 4B is a diagram A three-dimensional view of 4A’s exterior assembly from another angle. The detection device mainly includes a fixed part 20 and a movable part 30 . in:

[0024] The fixed part 20 is a fixed part locked on a stable platform such as a test table or other supporting mechanism, and is made of a material with good thermal conductivity. At least one heating element 22 is pierced inside the fixed part 20, such as an electric heating rod, resistance coil, quartz tube, positive temperature coefficient material (PTC), etc.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com