Machining apparatus for digital control rib cold bending machining and products produced thereby

A processing device and cold bending machine technology, applied in the field of hull construction technology, can solve the problems of reducing production efficiency, affecting the quality of line forming and forming accuracy, and over-bending, so as to achieve guaranteed accuracy, reliable measurement methods, high-quality precision and high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] In accompanying drawing 4, each numerical symbol represents:

[0016] 1-first length encoder, 2-main guide rail, 3-end frame, 4-second length encoder, 5-translation car, 6-skateboard trolley, 7-rib chuck, 8-rib, 9-first Processing chuck, 10-second processing chuck, 11-third processing chuck, 12-detection probe, 13-detection positioning tongue rod, 14-spring, 15-spring positioning rod, 16-spring stopper, 17- Grating, 18-nut, 19-screw, 20-motor, 21-measuring platform, 22-grating probe, 23-link shaft.

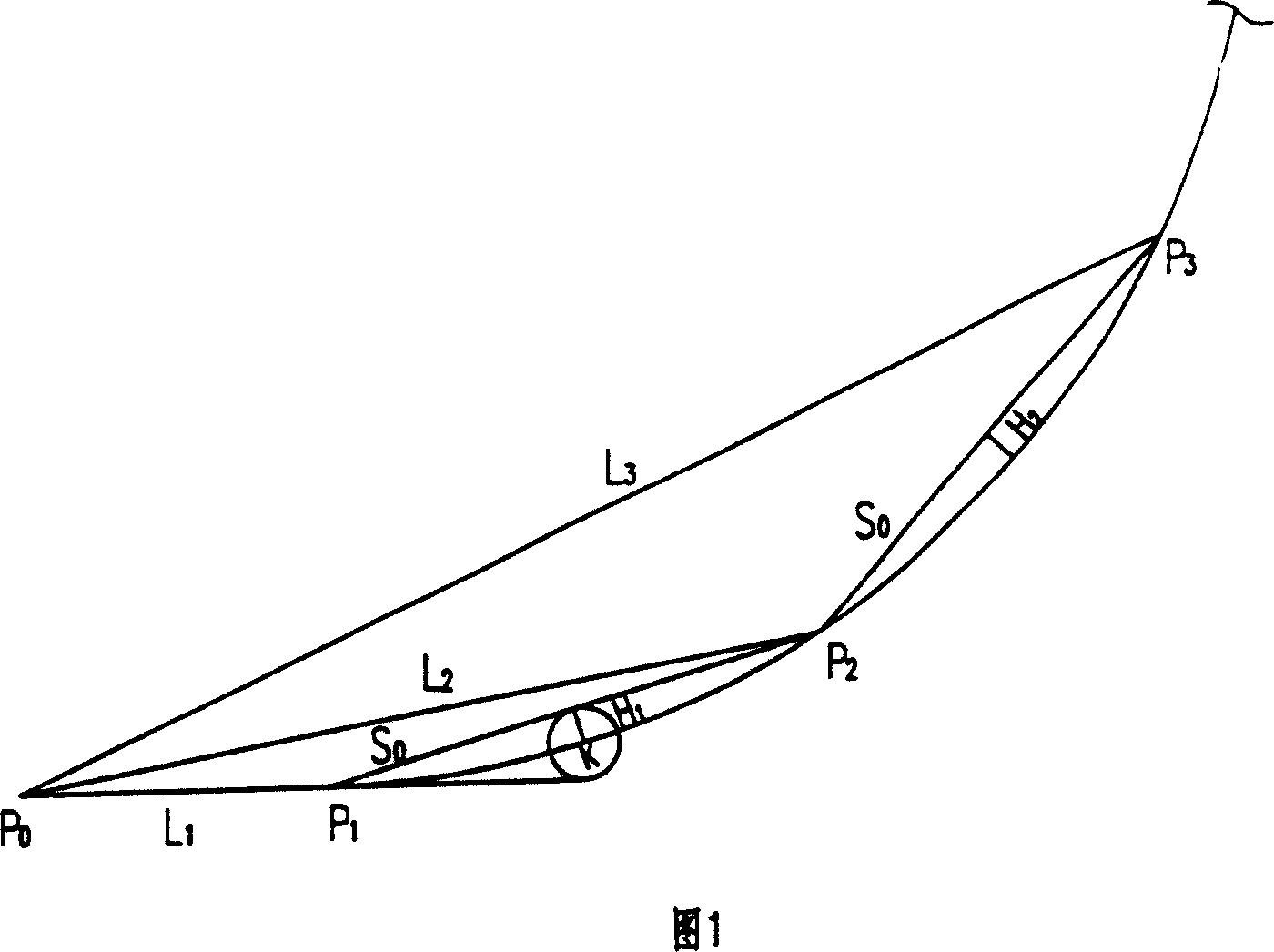

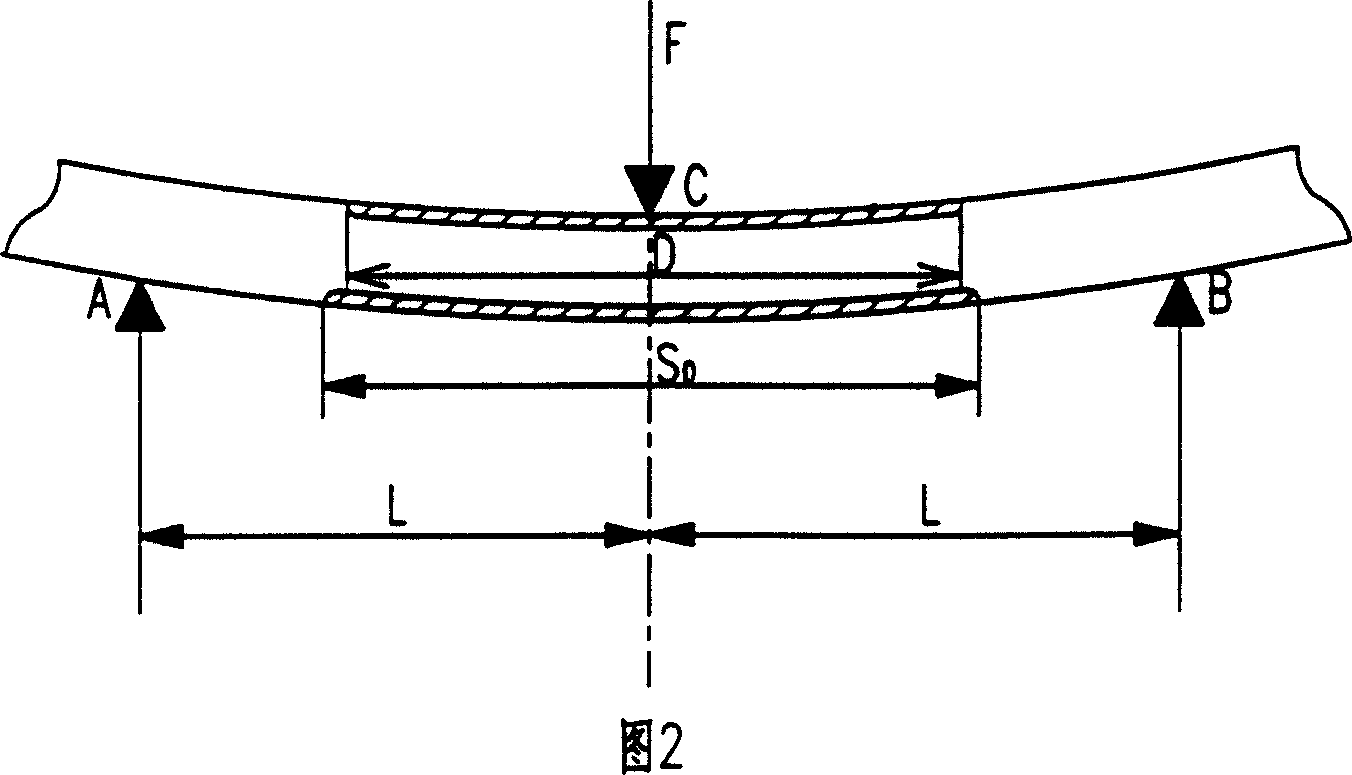

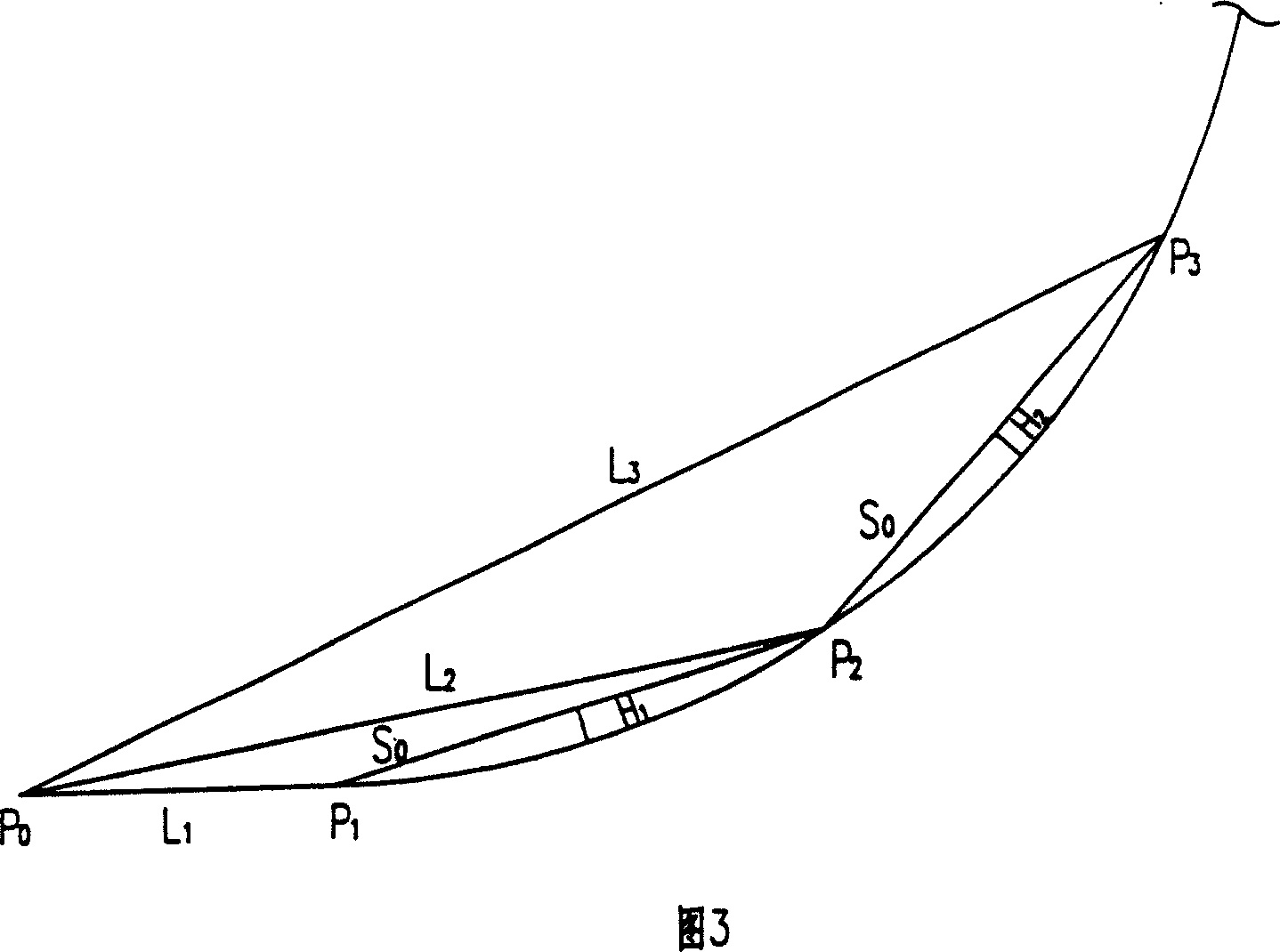

[0017] In the actual rib bending, the most sensitive part of the rib when it undergoes elastic and plastic deformation is the arch height of the bending arc. Therefore, in order to ensure the accuracy of the rib automatic bending and forming, it is necessary to use the arch height measurement method for processing.

[0018] A kind of processing met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com