Temperature correcting method in silicon sheet grade metal detection structure electromigration detection

A test structure and electromigration technology, which is applied in semiconductor/solid-state device testing/measurement, etc., can solve the problems of different final temperatures, inability to accurately extrapolate the electromigration life of metal test structures, etc., and achieve the effect of fast and accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

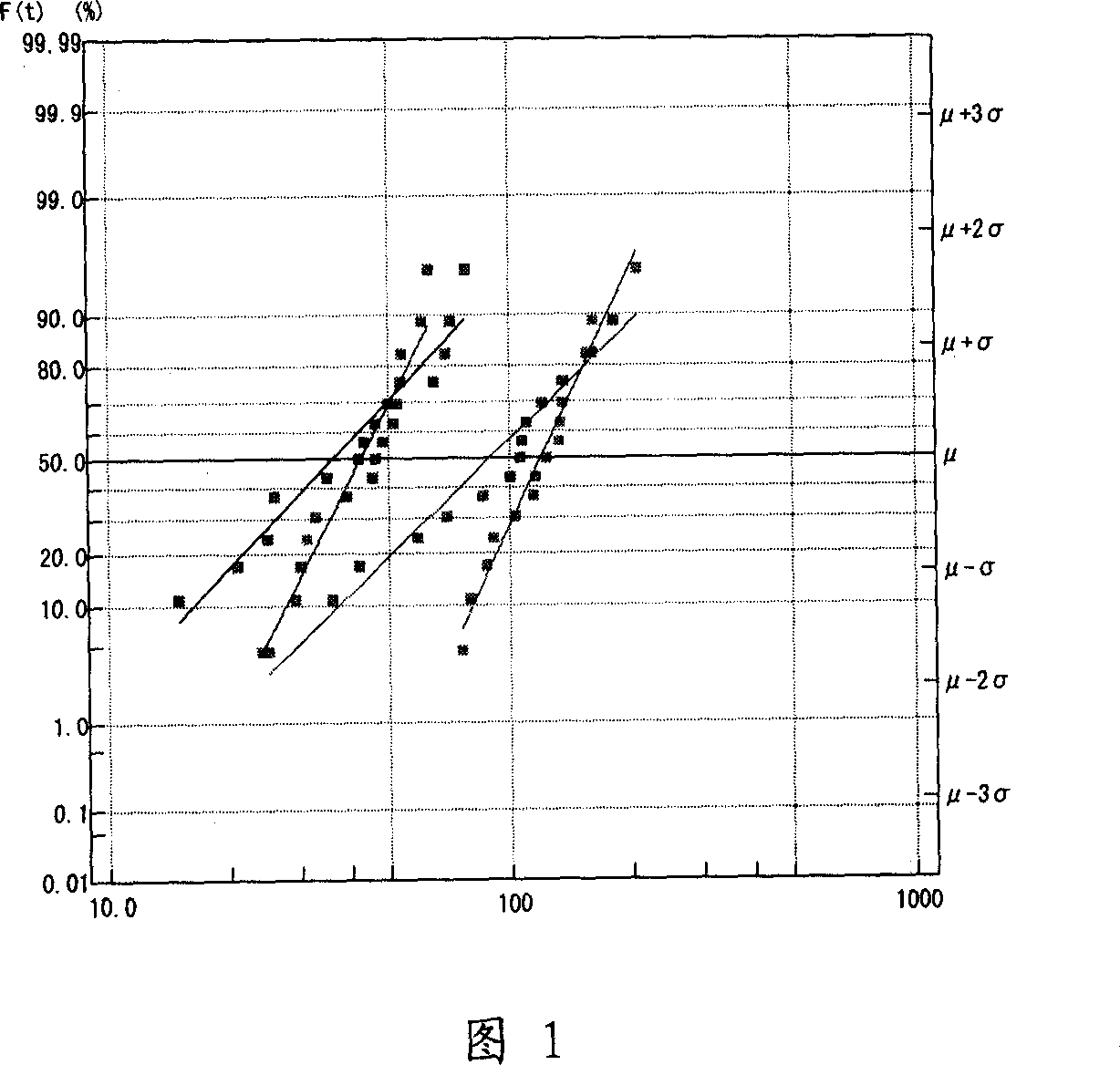

[0029] The electromigration test of silicon wafer-level metal test structure generally adopts a fixed accelerating current, and the temperature of the metal test structure is raised by the heat generated by the current. But because there are always subtle differences in each metal test structure, this leads to different temperatures for the same accelerating current.

[0030] The calculated electromigration lifetime in this case would be overly conservative due to the large dispersion of temperature, so it must be corrected reasonably.

[0031] The temperature correction method in the electromigration test of the silicon wafer-level metal test structure adopted in this embodiment mainly includes the following steps:

[0032] 1) Take a fixed accelerating current and rely on the heat generated by the current to increase the temperature of the metal test structure. The size of the fixed accelerating current should be selected according to the specific metal test structure, gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com