Electrochemical reducing process for preparing nanometer MOS2 particle

A molybdenum disulfide and nanoparticle technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of expensive raw materials, high reaction temperature, large product particle size, etc., to promote promotion and application, good monodispersity, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take by weighing 12.4g ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) Prepare a 100mL 0.1mol / L solution, heat to 50-60°C; then pass in hydrogen sulfide gas, absorb the tail gas with sodium hydroxide solution, and constantly adjust the pH value to 8.0 during the reaction process. After about 6 hours, the color of the solution turned into dark brownish red completely. After the reaction was completed, heating was stopped, and brownish red crystals could be obtained by cooling, which were purified and dried in vacuo.

[0027] Take by weighing 0.025g ammonium tetrathiomolybdate and 0.75g potassium chloride, dissolve in 100mL double-distilled water successively, pass nitrogen to remove dissolved oxygen; Electrode, the standard calomel electrode is the reference electrode, the platinum wire is the counter electrode, the constant current mode is adopted, and the current density is controlled at 2mAcm -2 , the reaction time is 30 minutes. After the reaction,...

Embodiment 2

[0030] The preparation of ammonium tetrathiomolybdate is the same as above.

[0031] Then take by weighing 0.025g ammonium tetrathiomolybdate, 0.75g potassium chloride and 0.273g tetraoctyl ammonium bromide, dissolve in 100mL double-distilled water successively, nitrogen gas removes dissolved oxygen; And in the self-made electrochemical reaction cell Graphite is used as the working electrode, the standard calomel electrode is used as the reference electrode, and platinum wire is used as the counter electrode. The constant current mode is adopted, and the current density is controlled at 2mAcm -2 , the reaction time is 30 minutes. After the reaction, there was black sediment at the bottom of the reaction tank, which was filtered, washed and dried to obtain the target product.

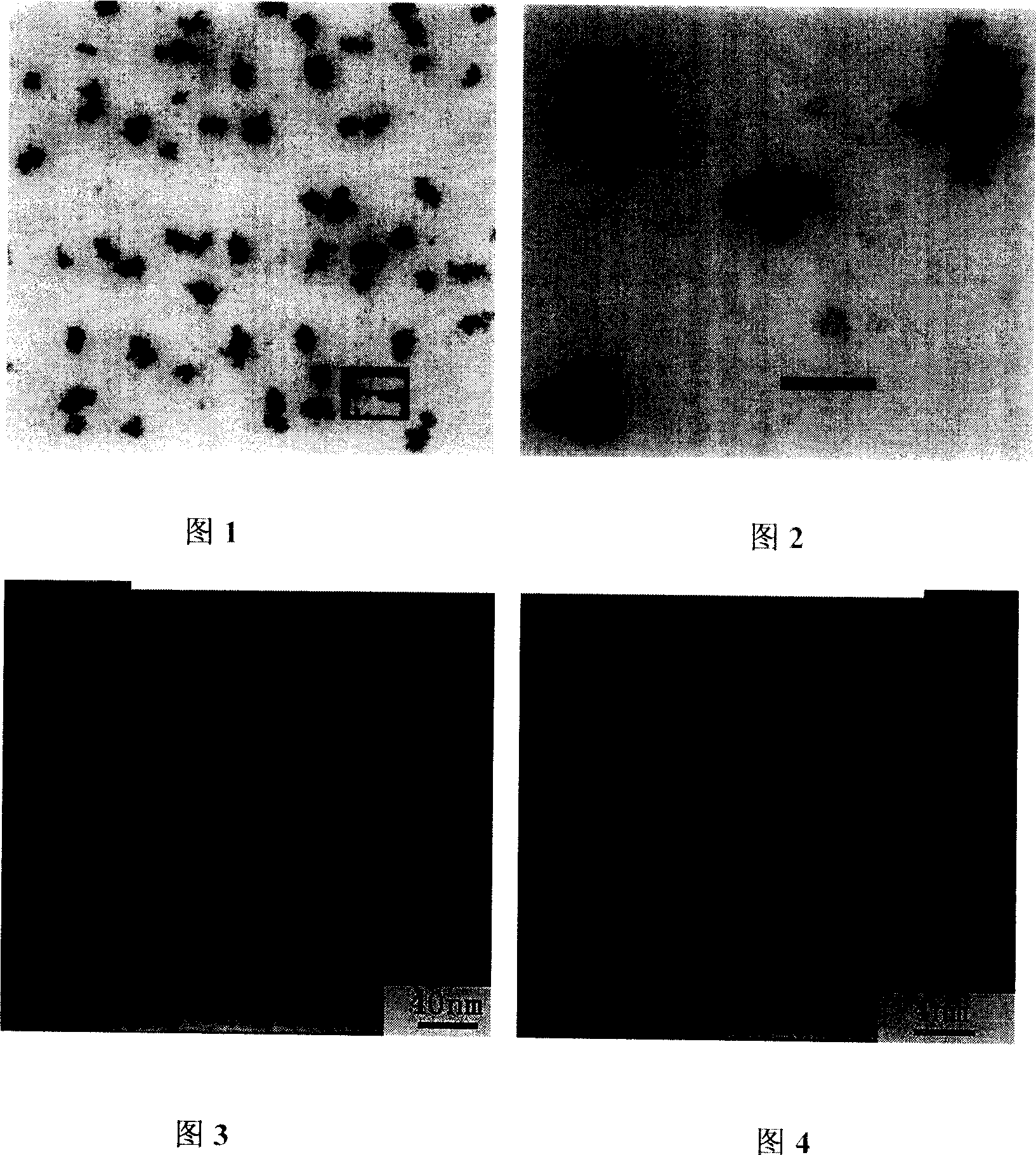

[0032] Figure 3 and Figure 4 are transmission electron microscope photographs of molybdenum disulfide nanoparticles obtained under the condition of the presence of surfactants at different magnification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com