Production of naphthenic lube oil and base oil

A naphthenic lubricating oil and production method technology, which are applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process and other directions, can solve the problems of low yield and the like, and achieve the effects of increasing yield and improving oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

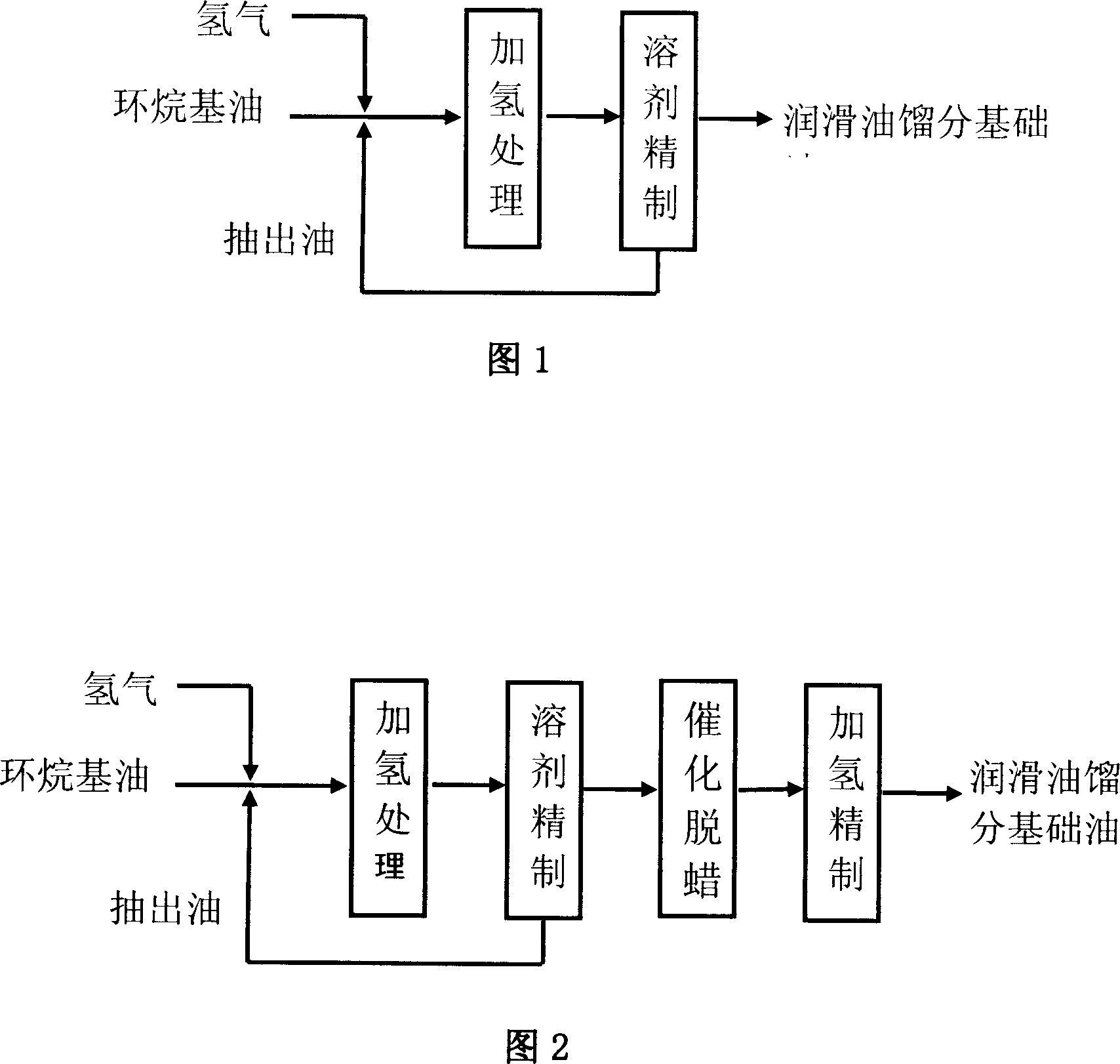

[0038] This example processes naphthenic base oil according to the process shown in Figure 1 to produce naphthenic lubricating oil base oil. Naphthenic feedstock oil, hydrotreating reaction conditions, and solvent refining operating conditions are the same as in Comparative Example 1. However, the raw material oil is a mixed oil of raw material oil 1 and furfural refined extracted oil (derived from comparative example 1), wherein the furfural refined extracted oil accounts for 15% of the total weight of the raw material oil. The product oil properties are listed in Table 3. The properties of the product oil listed in Table 3 show that the product oil obtained by the method of the present invention can not only be used as ordinary transformer oil, but also meet the quality requirements of ultra-high voltage transformer oil.

[0039] Table 1

[0040] Raw oil 1

Raw oil 2

Density(20℃) / g·cm -3

0.9078

0.9430

Kinematic viscosity / mm 2 ·s ...

example 2

[0048] This example processes naphthenic oil according to the process shown in Figure 2 to produce naphthenic lubricating oil base oil. Naphthenic oil, hydrotreating reaction conditions, solvent refining operating conditions, catalytic dewaxing reaction and hydrofining reaction conditions are the same as Comparative Example 2, and the difference is that feedstock oil is feedstock oil 2 and furfural refining extraction oil (derived from the refining of furfural The mixed oil of ratio 2), wherein the furfural refined extraction oil accounts for 10% of the total weight of the raw material oil. The product oil properties are listed in Table 5. The properties of the product oil listed in Table 5 show that the product obtained by the method of the present invention fully meets the standard of hermetic refrigerating machine oil and can be used as hermetic refrigerating machine oil.

[0049] Table 4

[0050] Hydrotreating process conditions

Hydrogen partial pressure / MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com