Filling of pressure vessels with cryogenically solidified gas

A low-temperature liquefied gas, pressure vessel technology, applied in pressure vessels, non-pressure vessels, equipment installed in pressure vessels, etc., can solve the high operation and maintenance costs, high investment costs, piston or diaphragm compressors. pressure and other problems, to achieve the effect of good measurement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

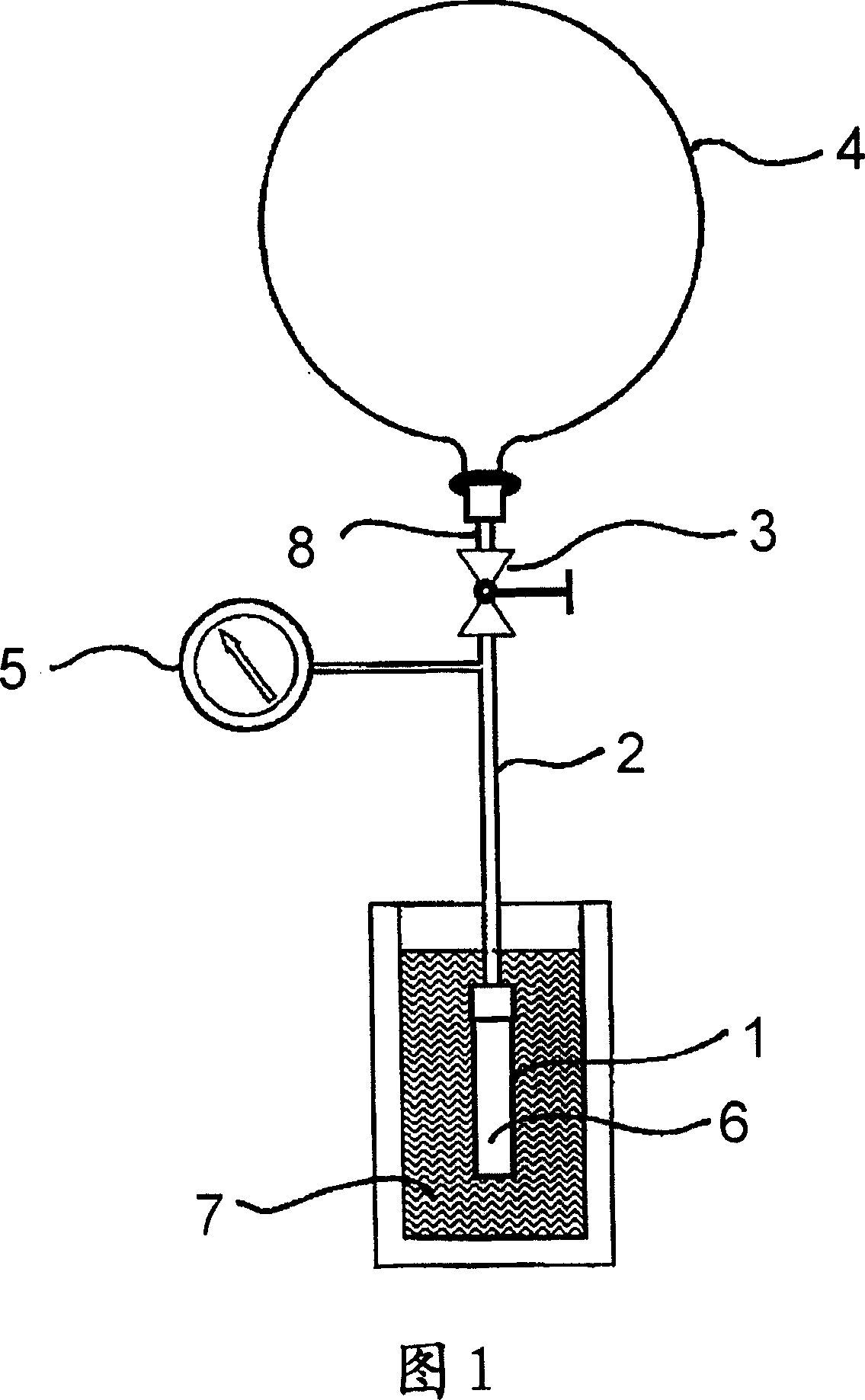

[0039] Figure 1 shows a pressure vessel 1, a filling tube 2 with a pipe connection 8, a shut-off valve 3, a gas cylinder 4 filled with argon (1 bar, 15 °C), a pressure gauge 5, argon ice in the pressure vessel 1 6 and a pool with liquid nitrogen 7 .

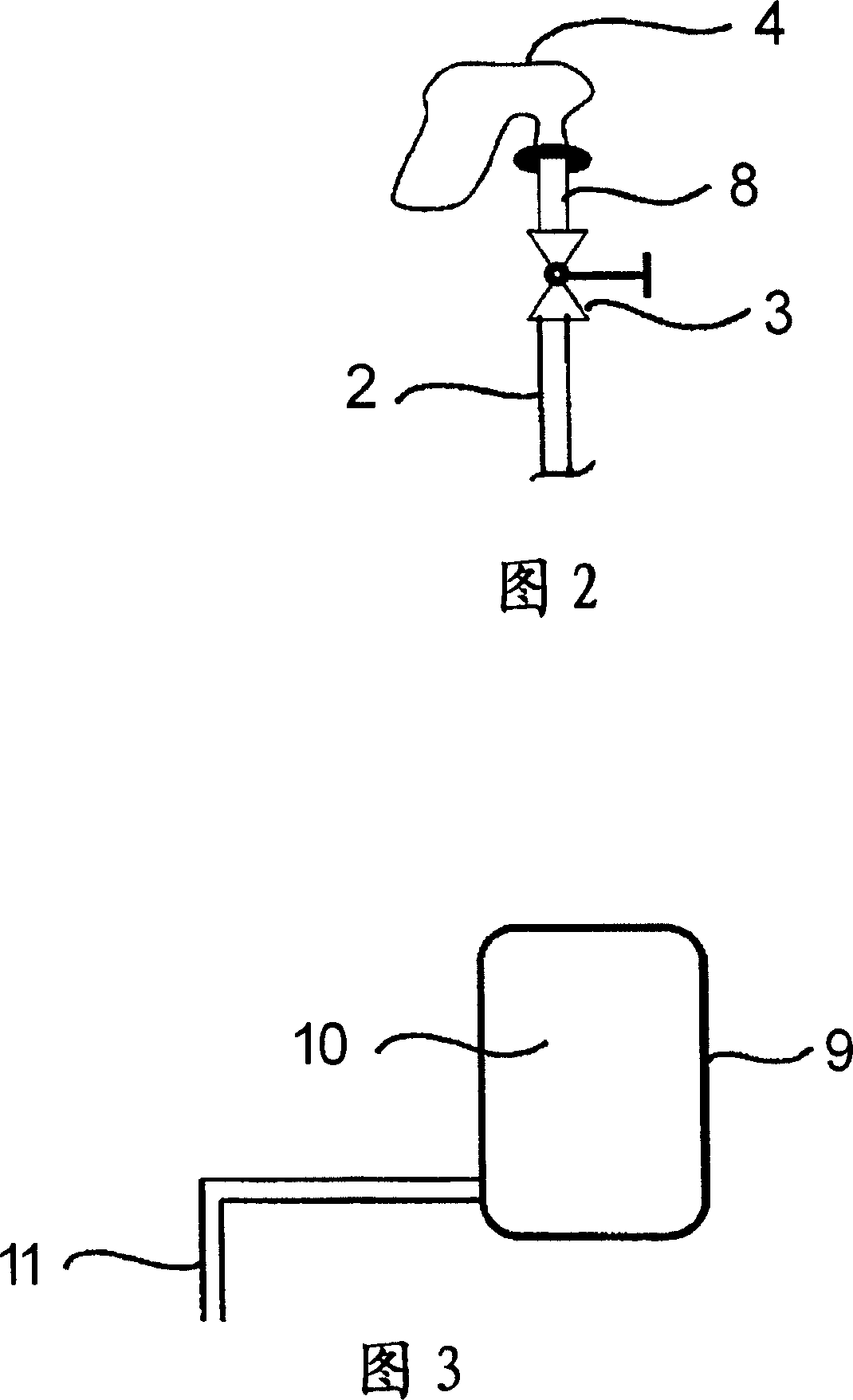

[0040] To determine the increase in density, a defined mass of argon from cylinder 4 is frozen to a precalculated container volume. To this end, a gas cylinder 4 is connected via a thin-walled tube 2 to a container 1 immersed in liquid nitrogen 7 . Once the air cylinder 4 has been emptied ( FIG. 2 ; showing in detail the emptied cylinder of the apparatus of FIG. 1 ), the shut-off valve 3 is closed and the container 1 can be removed from the liquid nitrogen bath. The pressure increase in the test vessel 1 due to the warming of the cold argon can be monitored using a pressure gauge 5 . The final pressure corresponding to the filling mass is reached after complete warming to ambient pressure.

[0041] FIG. 2 shows the situation w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com