Composite partile, nickel-hydrogen secondary cell negative-pole and cell and method for making same

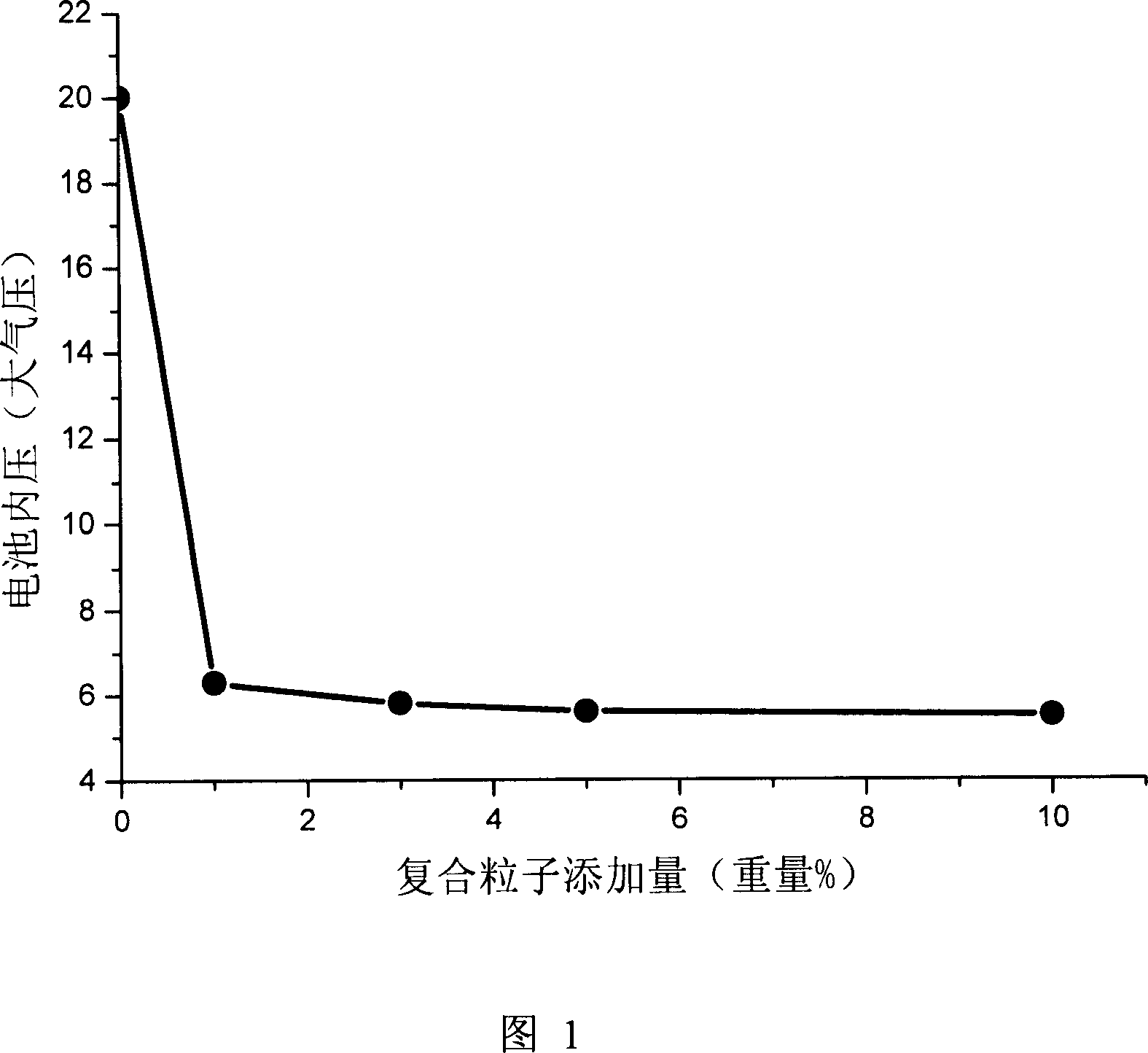

A composite particle, negative electrode conductive technology, applied in battery electrodes, alkaline storage battery electrodes, alkaline storage batteries, etc., can solve problems such as poor internal pressure performance of nickel-metal hydride secondary batteries, and achieve the effect of improving internal pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the composite particle provided by the invention comprises oxidizing the surface of the cobalt monoxide particle into tricobalt tetroxide in an oxidative atmosphere of 80°C-150°C.

[0022] Wherein, the oxidizing atmosphere can be various conditions that can oxidize cobalt monoxide into tricobalt tetroxide. For example, preferably, the cobalt monoxide particles are heated to 80°C-150°C in the presence of oxygen, and the surface of the particles Cobalt monoxide is oxidized to tricobalt tetroxide to obtain composite particles having tricobalt tetroxide formed on the surface. By controlling the reaction time, the amount of tricobalt tetroxide on the surface of the composite particles can be controlled. For example, the reaction time is 0.2-6 hours, preferably 0.5-5 hours. Therefore, in the obtained composite particles, based on the total weight of the composite particles, the content of tricobalt tetroxide is 2-60% by weight, preferably 5-50% by we...

Embodiment 1

[0040] This example is used to illustrate the composite particle provided by the present invention and its preparation method.

[0041] Cobalt monoxide particles with an average particle size of 3 microns were placed in an oven at 120°C and heated for 2 hours, and the oven was connected to the atmosphere. According to X-ray diffraction analysis, the surface of composite particles has formed Co 3 o 4 .

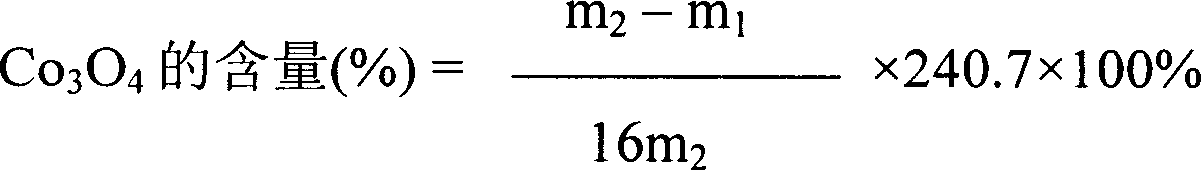

[0042] Measure the weight m of cobalt monoxide particles respectively 1 and the weight of the composite particle m 2 , calculate Co according to 3 o 4 The content in the composite particles is 10% by weight.

[0043]

Embodiment 2

[0045] This example is used to illustrate the composite particle provided by the present invention and its preparation method.

[0046] Cobalt monoxide particles with an average particle size of 0.2 microns were placed in an oven at 90° C. for 4 hours and heated for 4 hours, and the oven was connected to the atmosphere. According to X-ray diffraction analysis, the surface of composite particles has formed Co 3 o 4 . Determination of Co according to the same method as in Example 1 3 o 4 The content in the composite particles is 45% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com