Falling ball impact test machine

A technology of impact testing machine and falling ball, which is applied in the direction of testing the strength of materials, measuring devices, instruments, etc. by using one-time impact force. It can solve the problems of difficult control of height, cumbersome operation, and steel balls are easy to rebound and hurt people, so as to prevent human errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

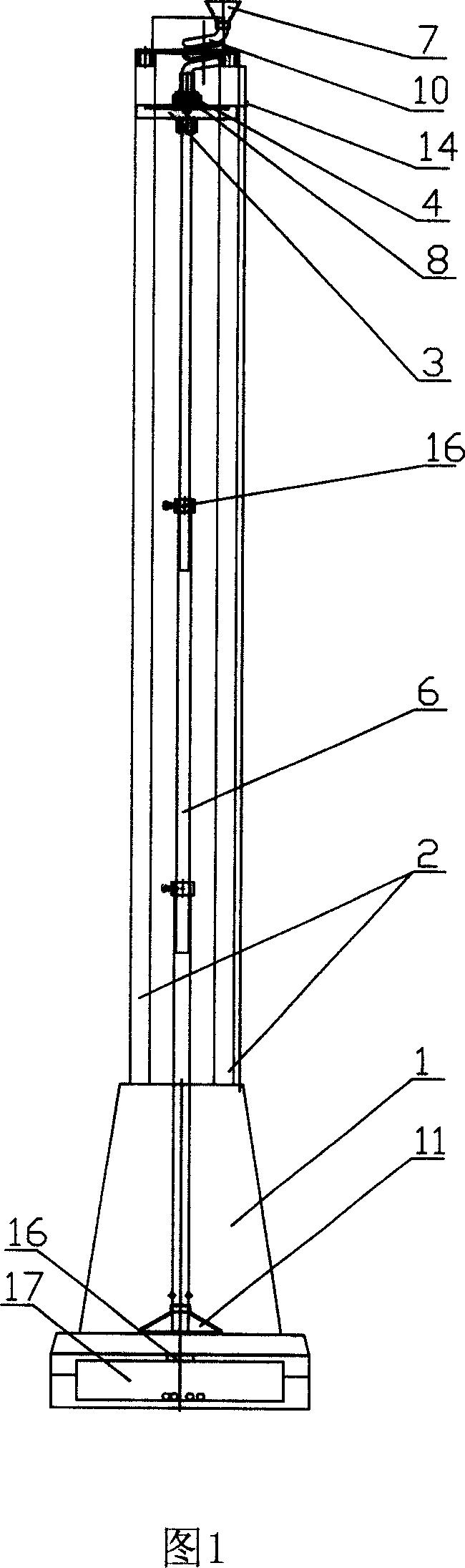

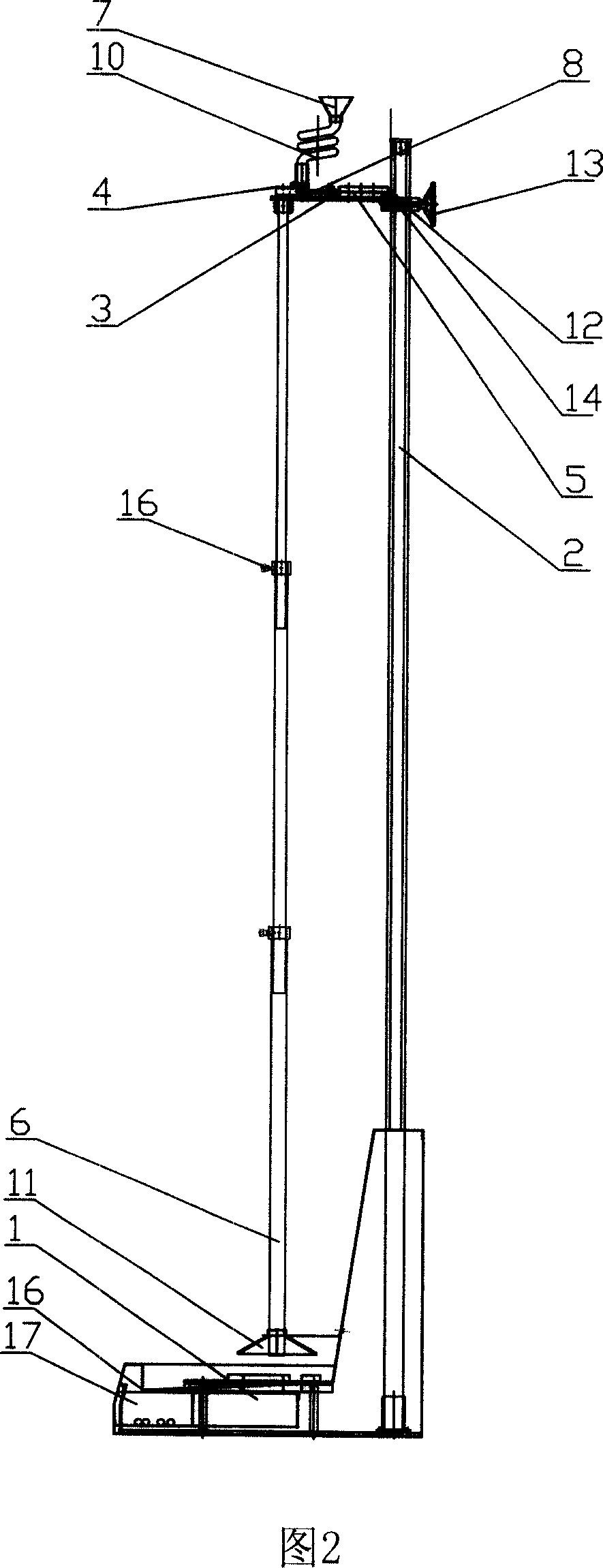

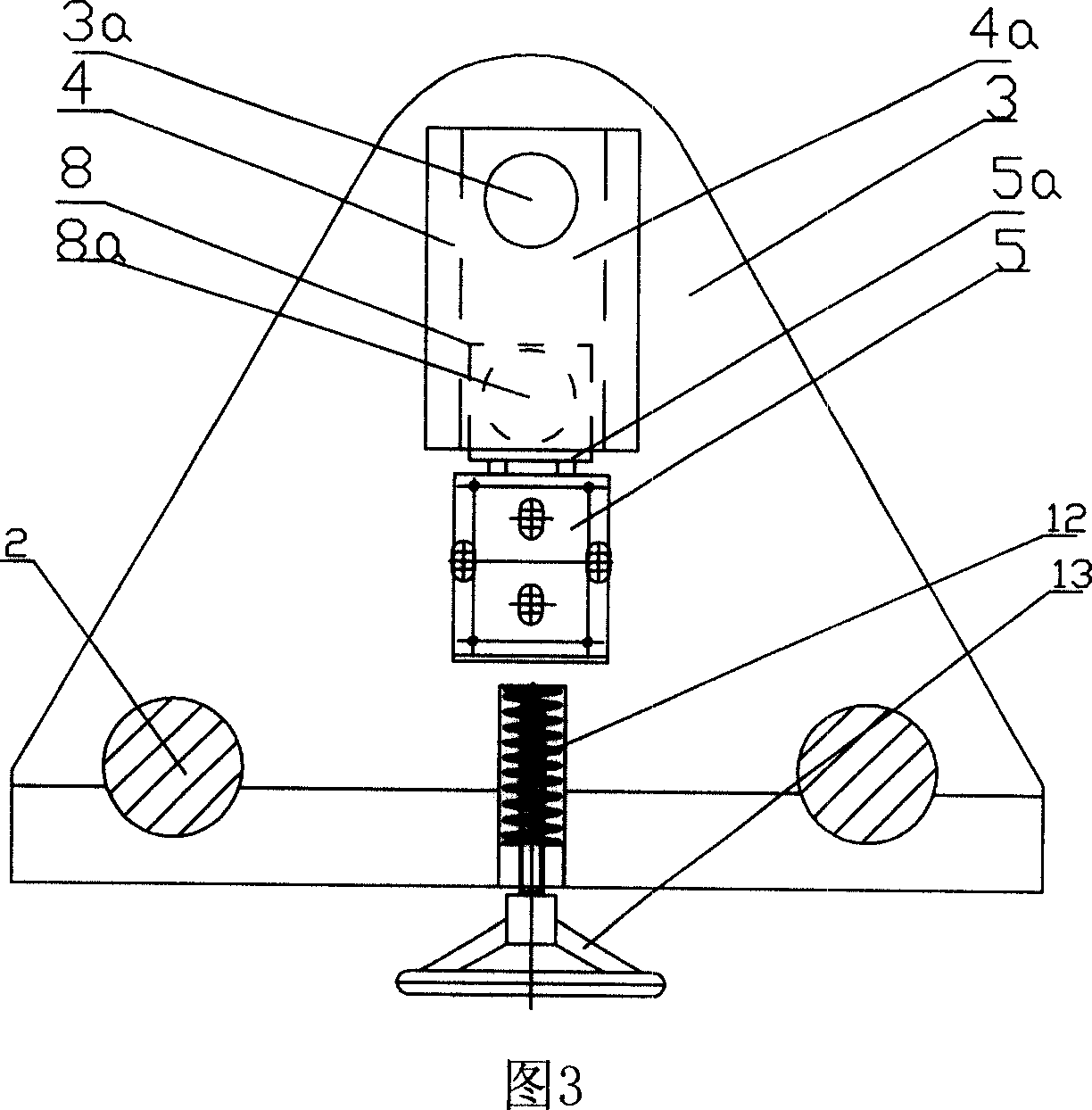

[0024] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5: a falling ball impact testing machine includes a column 2 installed on the base 1, and a lifting platform 3 set on the column 2, the lifting platform 3 and column 2 are fixed by bolt 12, and the outer end of bolt 12 is fixed with handwheel 13;

[0025] As shown in Figure 3: the bolt 12 is covered with a spring to abut against the lifting platform 3, and the hand wheel 13 is turned to adjust the tightness between the lifting platform 3 and the column 2, so that the lifting platform 3 can slide up and down on the column 2.

[0026] Said lifting platform 3 is screwed with "冂" shaped block 4 and cylinder 5, wherein between "冂" shaped block 4 and lifting platform 3 forms rolling ball channel 4a; The ball window 4b is connected to the funnel 7; the lifting platform 3 at the other end of the rolling ball chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com