Monolithic integrated sensor chip for measing three parameters of pressure difference, absolute pressure and temperature and its making process

A sensor chip, monolithic integration technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, semiconductor/solid-state device components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., to achieve performance Effects of stabilization, improved precision, and extended functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

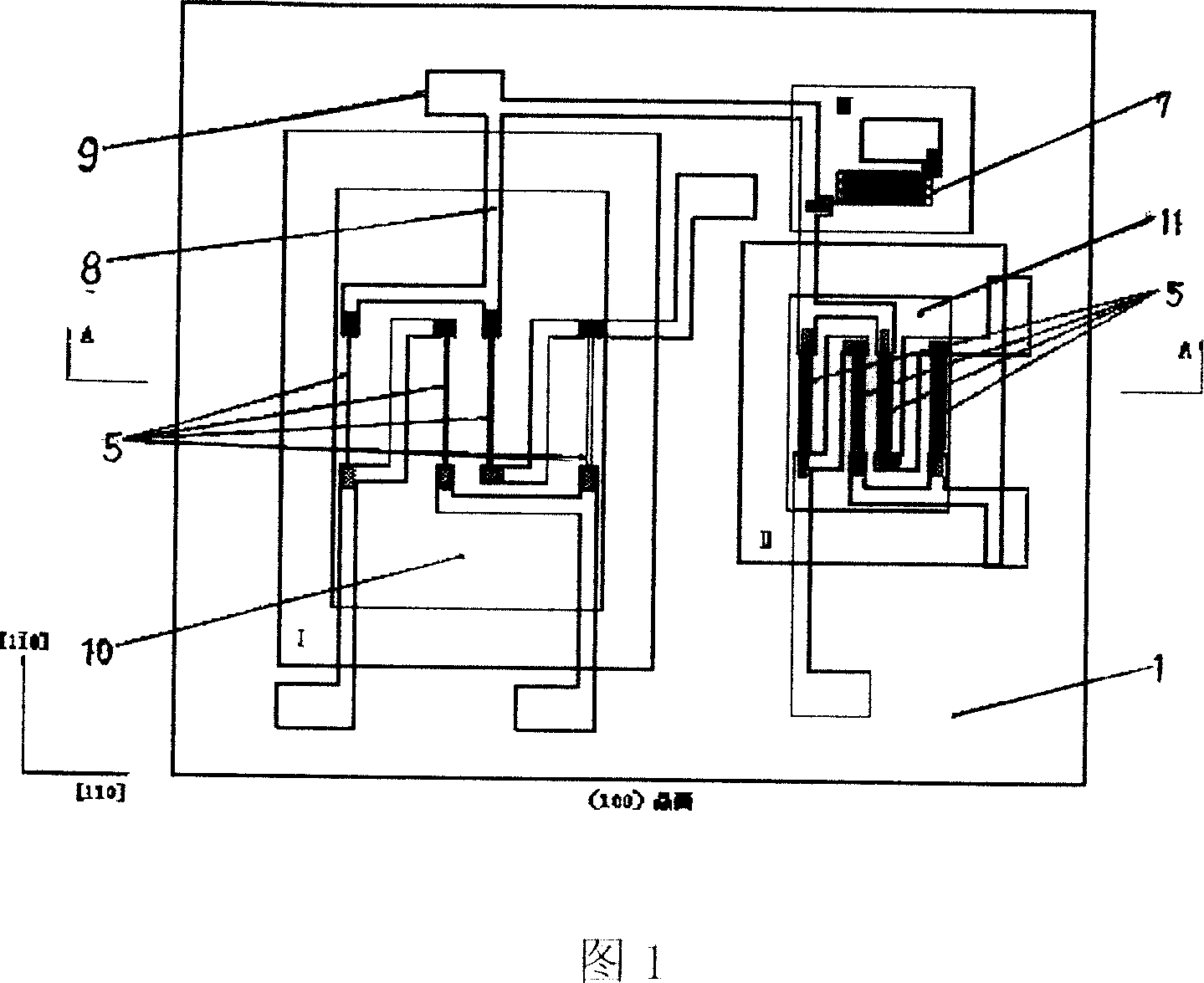

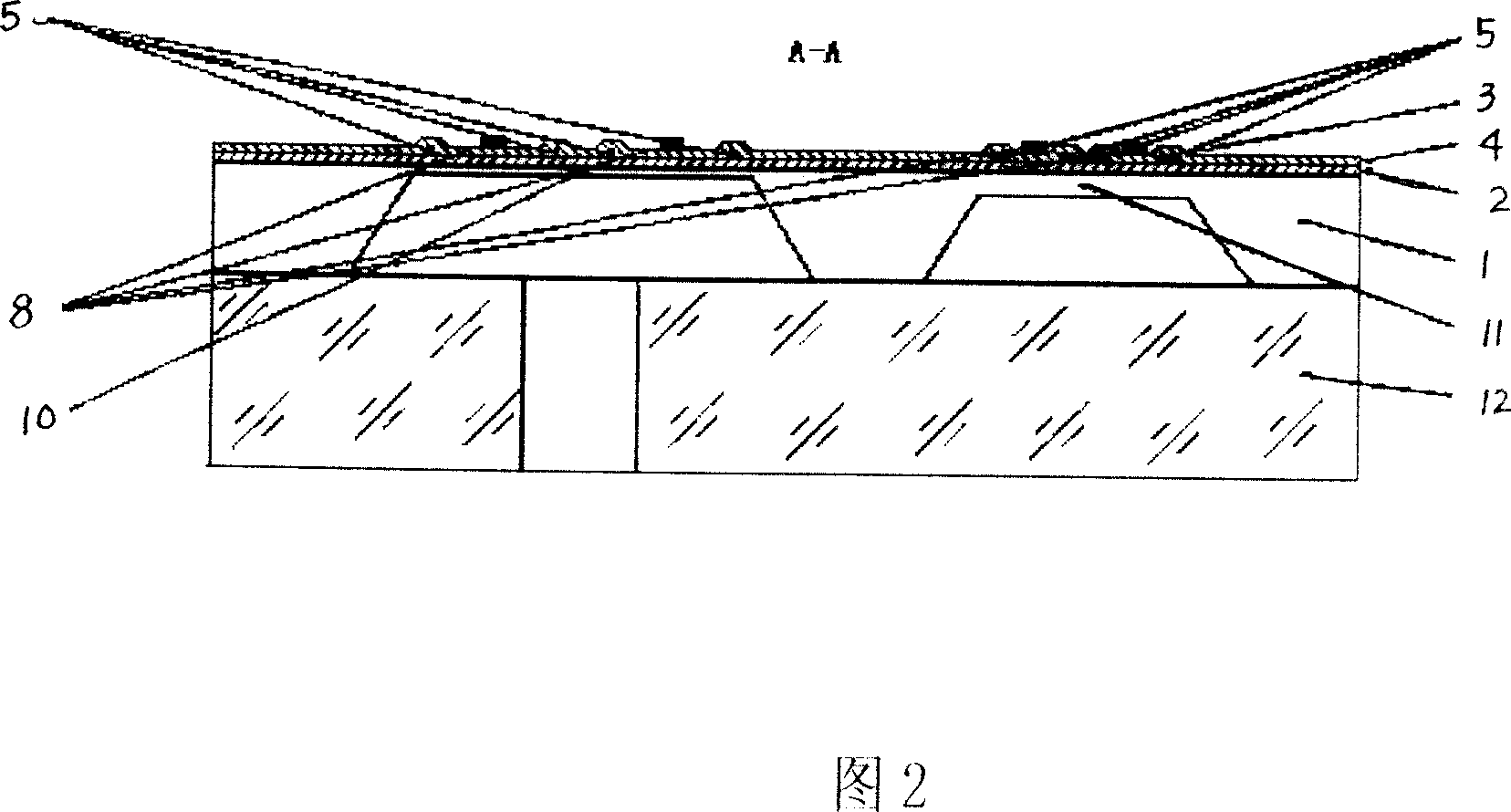

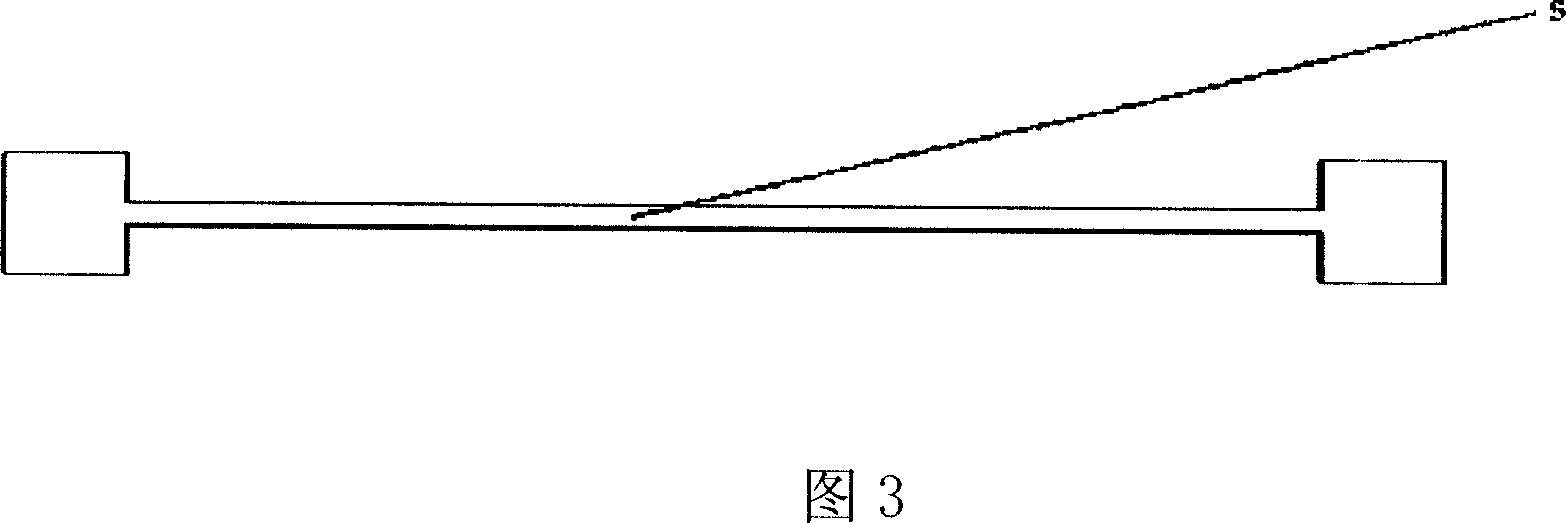

[0019] With reference to the drawings, the structure of the monolithic integrated sensor chip with three parameters of differential pressure / absolute pressure / temperature of the present invention is: adopting SOI (100) crystal plane double-polished silicon monolithic wafer, as shown in Figure 1-3, with an area of 3.5×4.0mm 2 The middle part of the substrate of the silicon sensitive chip 1 forms two relatively independent differential pressure sensitive membrane cavity areas and absolute pressure sensitive diaphragm cavity areas: one area is made of four independent P-type silicon resistors on the front side as differential pressure The sensitive resistor 5 is distributed on the differential pressure sensitive diaphragm 10 formed by anisotropic corrosion technology along the [110] crystal direction stress concentration. The thickness of the diaphragm is 10-100um. The two ends of the resistance strip of the differential pressure sensitive resistor 5 are insulated A lead hole is op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com