Soldering iron with replaceable tip

A soldering iron tip, soldering iron technology, applied in soldering irons, manufacturing tools, welding positions, etc., can solve the problem of high operating cost of composite heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

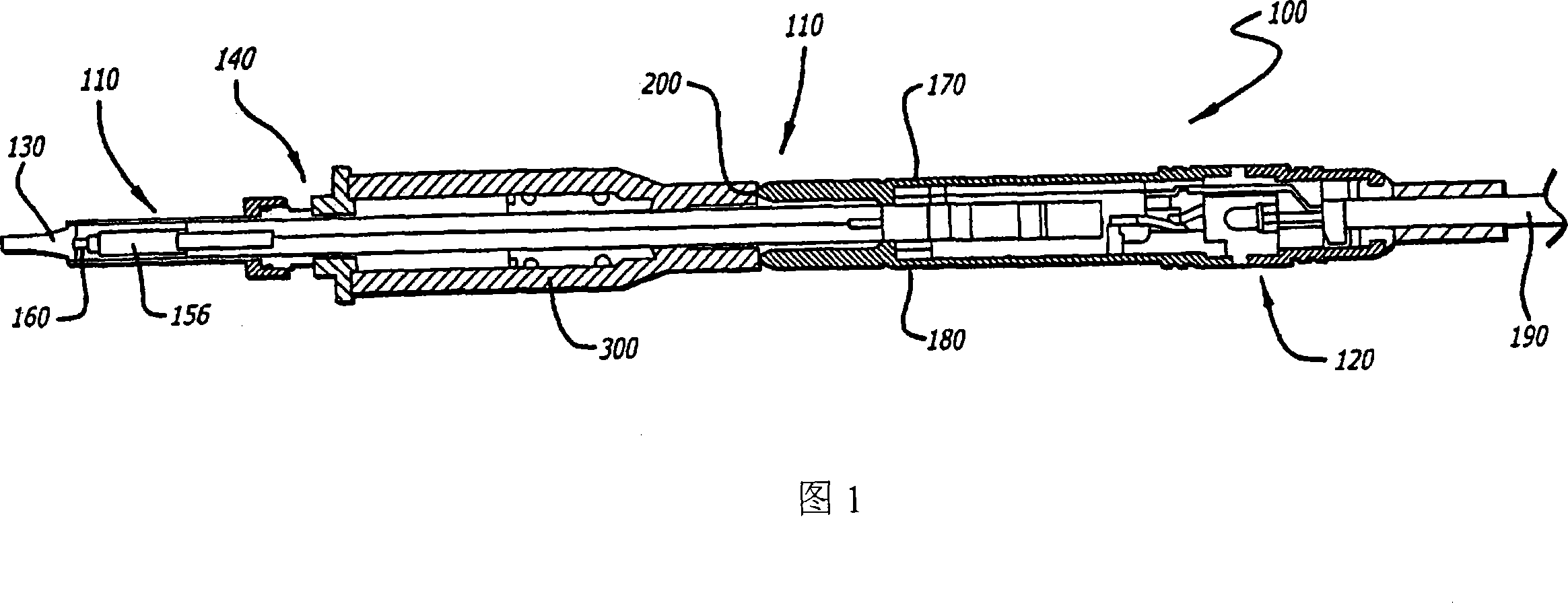

[0073]Referring to FIG. 1 , a soldering iron of the present invention is generally indicated at 100 . The soldering iron 100 includes a heating assembly 110 (or heating unit), shown generally at 110, a connection assembly 120, a replaceable tip cap 130, and a copper or copper alloy 154 removably retaining the tip cap 130 to the heating assembly 110. Retention assembly 140 on conical working head 150 . The heating assembly 110 may also include a heating unit 156 and a temperature sensor 160 . The heating assembly 110 is detachable from the connection assembly 120 for replacement purposes. The heating assembly 110 is snap-fitted to the front end of the connection assembly 120 and retained therein, for example by an O-ring 170 . Soldering iron 100 of FIG. 1 and its structure, components, and operation may perhaps be described from U.S. Patent Application Serial No. 10 / 264,718, filed October 4, 2002, entitled "Soldering Iron Tip and Soldering Iron" (US 2004 / 0065653), and 2002 F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com