A MOS FET tube and its manufacturing method

A technology of field effect transistors and substrates, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting the speed performance of digital circuits and reduce the intrinsic performance of transistors, so as to improve speed performance and reduce gate leakage Overlap capacitance, effect of reducing gate-drain fringe capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

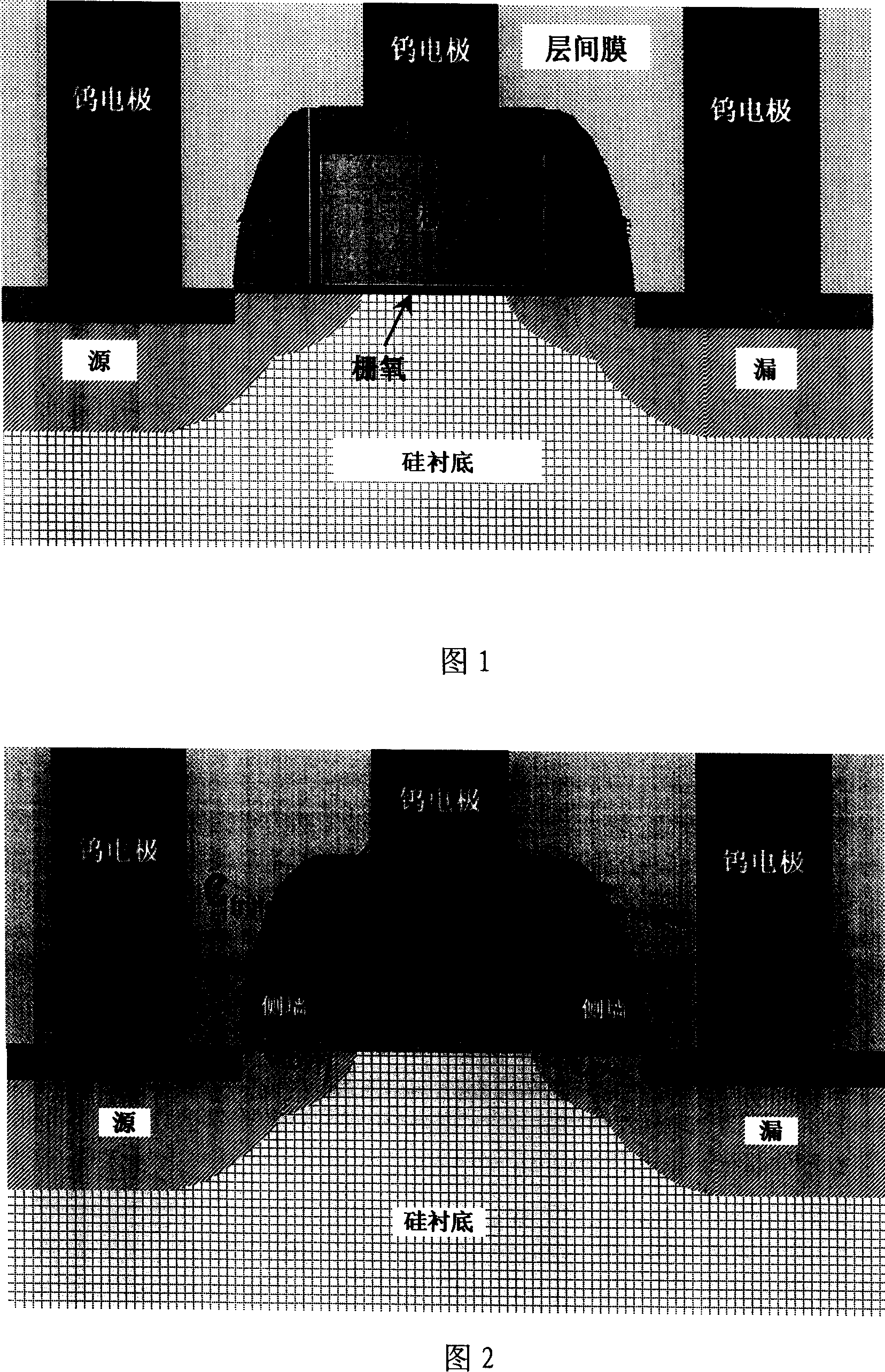

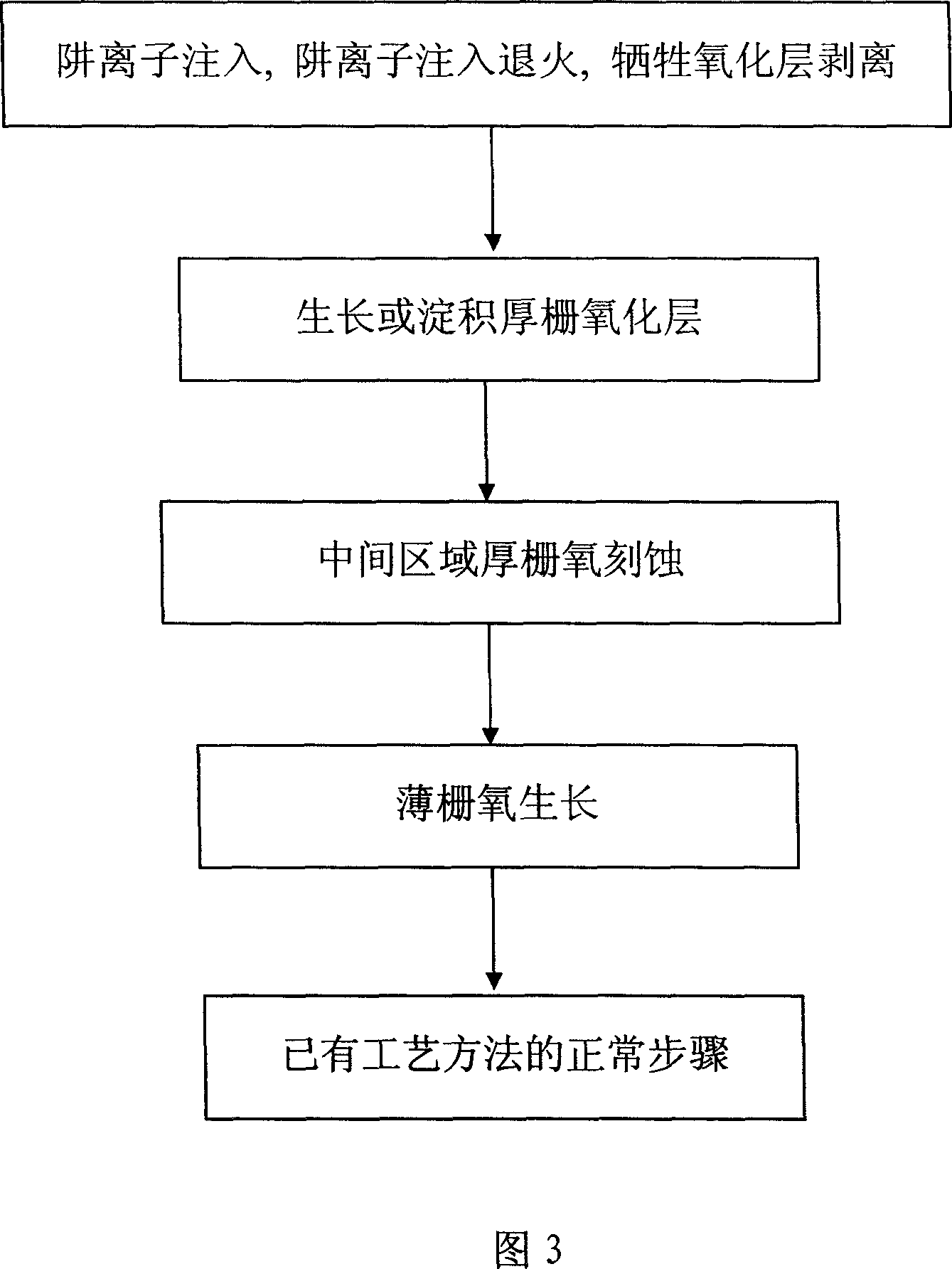

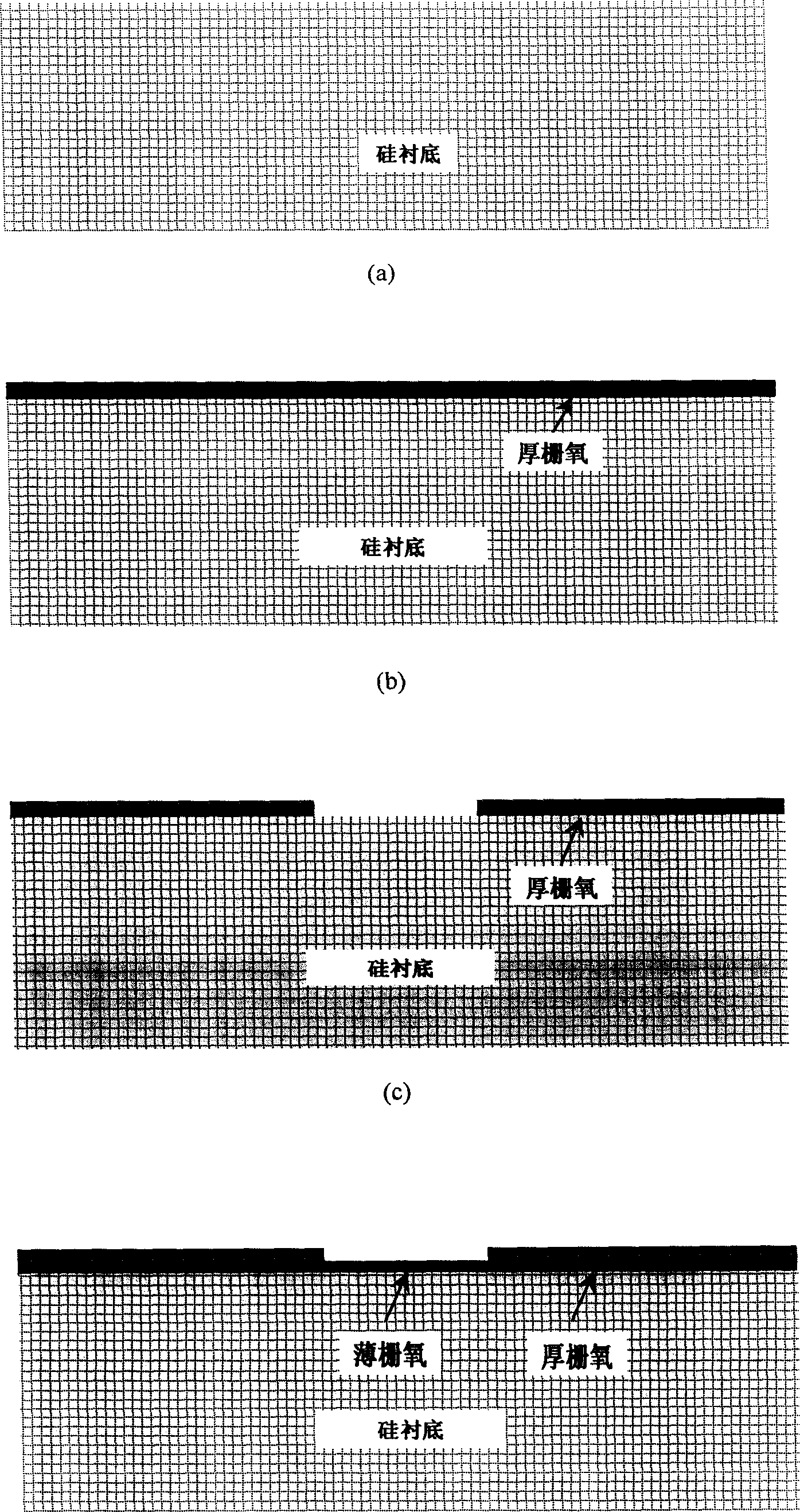

[0016] As shown in Figures 3 and 4, a method for manufacturing a MOS field effect transistor includes the following steps. First, the well ion implantation, the well ion implantation annealing, and the stripping of the sacrificial oxide layer are completed in the conventional process flow, as shown in Figure 4 ( a); The second step is to thermally grow or deposit a thick gate oxide layer. The thickness of the thick gate oxide should be 2 to 5 times the thickness of the thin gate oxide grown in the subsequent process, see FIG. 4(b). Within the above range, the specific thickness of the thick gate oxide is optimally selected and determined according to the electrical characteristics of the transistor and related process conditions. The third step is to completely etch away the thick gate oxide in the middle region, see Figure 4(c). The edge of the thick gate oxide etching region is between the source / drain-substrate PN junction and the edge of the gate in the subsequent process....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com