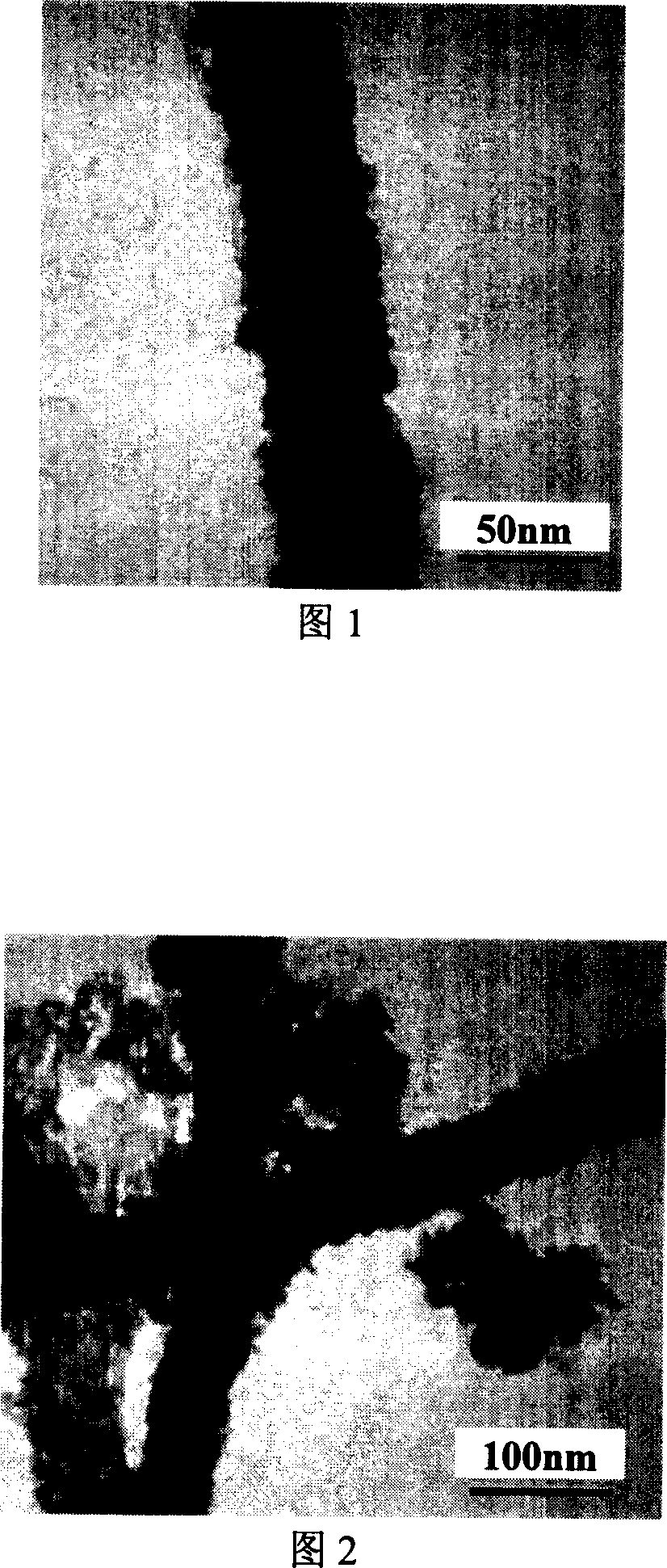

Preparing method of nano-Fe3O4 coating carbon nanotube magnetic composite material

A technology of ferroferric oxide and carbon nanotubes, applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve problems such as long reaction time, undiscussed magnetic properties of composite materials, and difficulty in controlling Fe, etc., to achieve light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) At room temperature, add 3 g of carbon nanotubes with a diameter of 10-20 nanometers into 150 ml of concentrated nitric acid, stir and mix for 30 minutes at a speed of 500 rpm, and ultrasonically disperse for 30 minutes. Medium reflux reaction for 4 hours, then lower the temperature of the reflux reaction mixture to 25°C, filter with a 0.85 μm filter membrane, wash and filter with deionized water until the pH is 7, and obtain carbon with functional groups such as carbonyl, hydroxyl, and carboxyl on the surface. Nanotubes and carbon nanotubes are not dried;

[0031] (2) Put the carbon nanotubes with functional groups such as carbonyl, hydroxyl, and carboxyl on the surface obtained in step (1) into deionized water, ultrasonically disperse for 30 minutes, stir and disperse for 30 minutes, so that the weight percent concentration of the suspension is 0.5%;

[0032] (3) ferrous chloride salt and ferric chloride are respectively made into the aqueous solution of appropria...

Embodiment 2

[0036](1) At room temperature, add 5 g of carbon nanotubes with a diameter of 20-40 nanometers into 200 ml of concentrated nitric acid, stir and mix for 30 minutes at a speed of 500 rpm, and ultrasonically disperse for 30 minutes. Medium reflux reaction for 4.5 hours, then lower the temperature of the reflux reaction mixture to 25°C, filter with a 0.85 μm filter membrane, wash and filter with deionized water until the pH is 6.5, and obtain carbon with functional groups such as carbonyl, hydroxyl, and carboxyl on the surface. Nanotubes and carbon nanotubes are not dried;

[0037] (2) Put the carbon nanotubes with functional groups such as carbonyl, hydroxyl, and carboxyl on the surface obtained in step (1) into deionized water, and carry out ultrasonic or stirring dispersion, so that the concentration by weight of the suspension is 1%;

[0038] (3) ferrous chloride salt and ferric chloride are respectively made into the aqueous solution of appropriate concentration, by ferrous ...

Embodiment 3

[0042] (1) At room temperature, add 2.5 g of carbon nanotubes with a diameter of 40-60 nanometers into 150 ml of concentrated nitric acid, stir and mix for 1 hour at a speed of 500 rpm, and ultrasonically disperse for 30 minutes. Reflux reaction in the bath for 4.5 hours, then lower the temperature of the reflux reaction mixture to 25°C, filter with a 0.85 μm filter membrane, wash and filter with deionized water until the pH is 7, and obtain carbonyl, hydroxyl, carboxyl and other functional groups on the surface Carbon nanotubes, carbon nanotubes are not dried;

[0043] (2) Put the carbon nanotubes with functional groups such as carbonyl, hydroxyl, and carboxyl on the surface obtained in step (1) into deionized water, and carry out ultrasonic or stirring dispersion, so that the concentration by weight of the suspension is 2%;

[0044] (3) ferrous chloride salt and ferric chloride are respectively made into the aqueous solution of appropriate concentration, by ferrous chloride:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com