Submarine oil pipeline and dedicated connector therefor

A technology for oil pipelines and special connections, which is applied in the direction of pipeline connection layout, pipes/pipe joints/fittings, pipes, etc., which can solve the problems of being easily corroded by seawater, low efficiency, and easy breakage of pipelines, so as to avoid overhead breakage and ensure safety , delivering smooth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

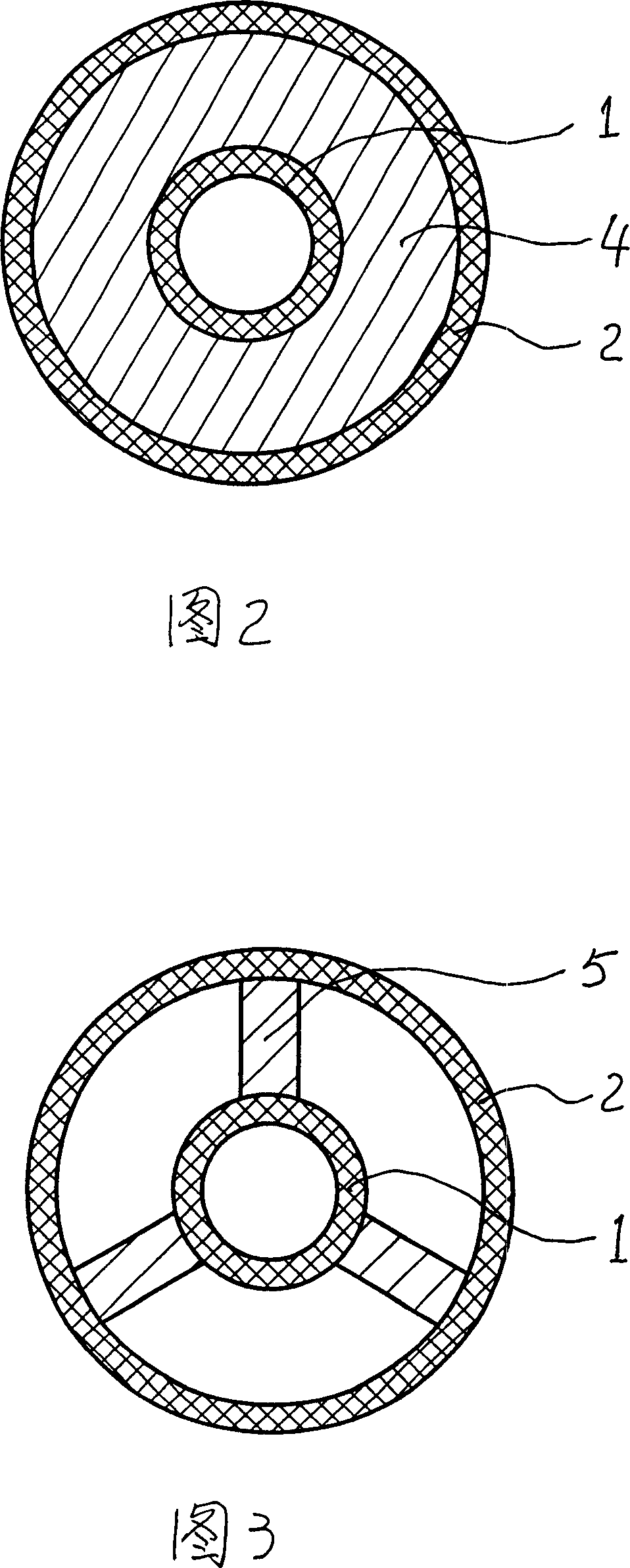

[0015] The structure and operating principle of the subsea oil pipeline and its connection end provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] As shown in Fig. 1, the structure schematic diagram of the subsea oil pipeline provided by the present invention and its fixed connection end includes an inner rubber hose 1 for transporting oil and an outer rubber hose 2 at a certain distance therefrom, and the inner, The outer rubber hose is made of rubber material. In order to form a certain space between the inner and outer rubber hoses, several annular support frames 4 (as shown in Fig. 2 ) forming independent sealed material chambers 3 are evenly arranged between the two. In order to increase the weight of the oil pipeline, some counterweights 5 such as gravel and iron sand are added in the independent sealed chamber 3 . In addition, in order to improve the insulation performance of the oil pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com