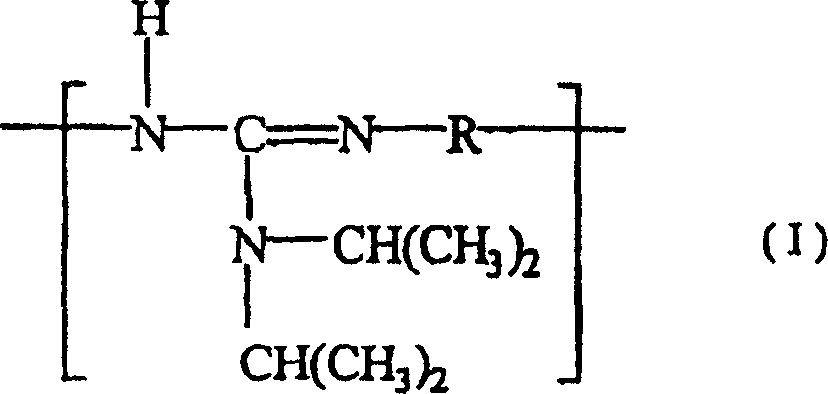

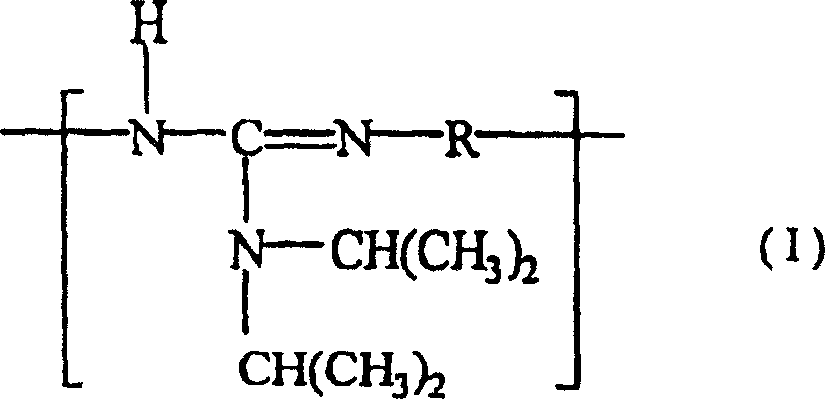

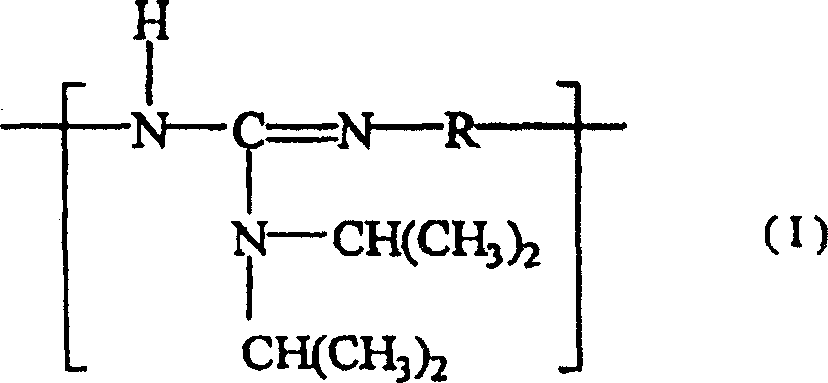

Modified polycarbodiimide composition and modified polycarbodiimide

A polycarbodiimide and carbodiimide technology, applied in the field of modified polycarbodiimide groups, can solve the problems of poor reactivity, adhesion, poor heat resistance, corrosion, etc., and achieve excellent heat resistance and adhesion. The effect of cohesiveness and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0140] Next, the present invention will be described in more detail by way of examples.

[0141] [Synthesis of aromatic polycarbodiimide]

Synthetic example 1

[0143] Into a 1-liter four-necked flask, 70.0 g of 4,4'-diphenylmethane diisocyanate (hereinafter referred to as MDI), 74.0 g of PTMG1000 (manufactured by Sanyo Chemical Industry Co., Ltd.), 320.0 g of toluene as a solvent, and methyl ethyl ketone ( MEK) 180.0g, which was immersed in a 90°C oil bath, and heated and stirred for 2 hours.

[0144] Then, 0.12 g of 3-methyl-1-phenyl-2-phosphorolene (hospholen)-1-oxide (hereinafter referred to as "carbodiimidization catalyst") was added, and the temperature was raised to 110°C. Carbodiimide reaction was performed for 5 hours to obtain a polycarbodiimide copolymer solution.

Synthetic example 2

[0146] In a 1-liter four-necked flask, 70.0 g of toluene diisocyanate (2,4-toluene diisocyanate: 2,6-toluene diisocyanate = 80:20 mixture, hereinafter referred to as TDI), PTMG1400 (Sanyo Chemical Industry Co., Ltd.) production) 50.0 g, which was immersed in an 80° C. oil bath, and heated and stirred for 3 hours. Then add 500.0 g of cyclohexanone as a solvent to form a uniform solution, add 0.16 g of a carbodiimidization catalyst, heat up to 130 ° C, and perform a carbodiimidization reaction for 6 hours to obtain polycarbodiimidization Amine Copolymer Solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com