Method and device for charging of blowing-in blast furnace without bell

A technology of charging and measuring method for opening a furnace, applied in the field of blast furnace ironmaking, can solve the problems of long measuring time, complicated measuring process, visual error, etc., and achieve the effect of saving material and manpower and accurate measuring data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

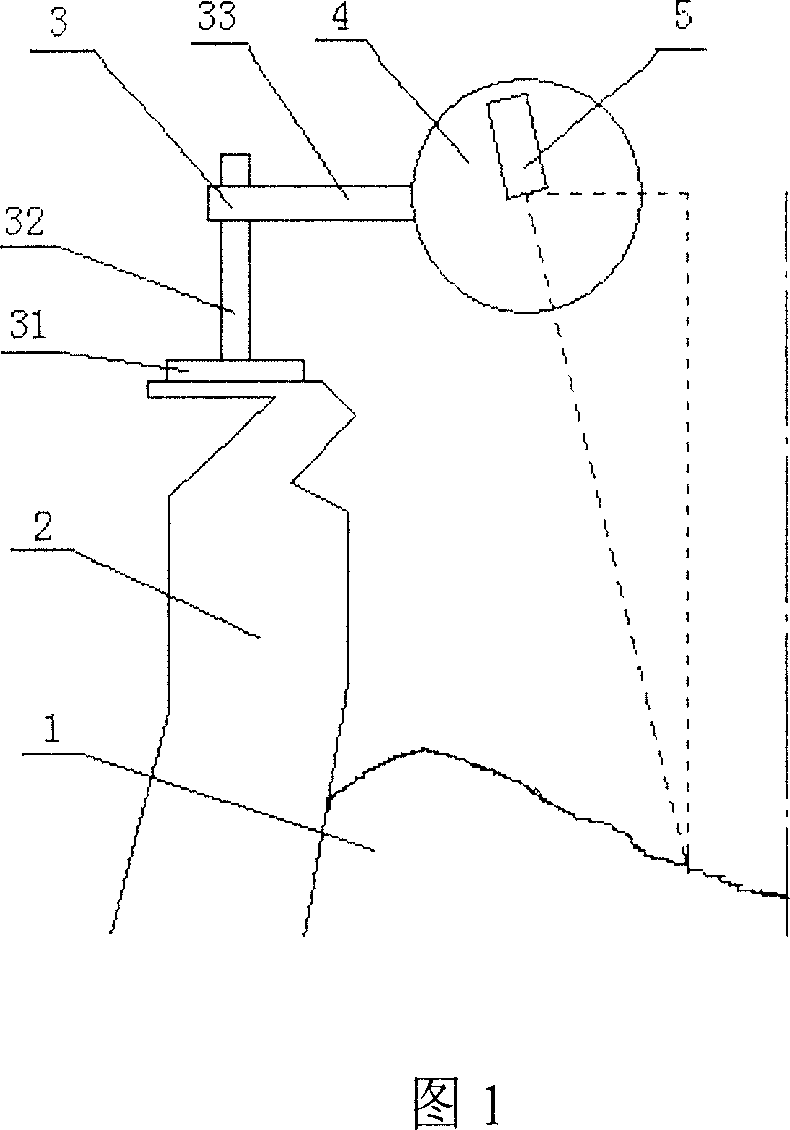

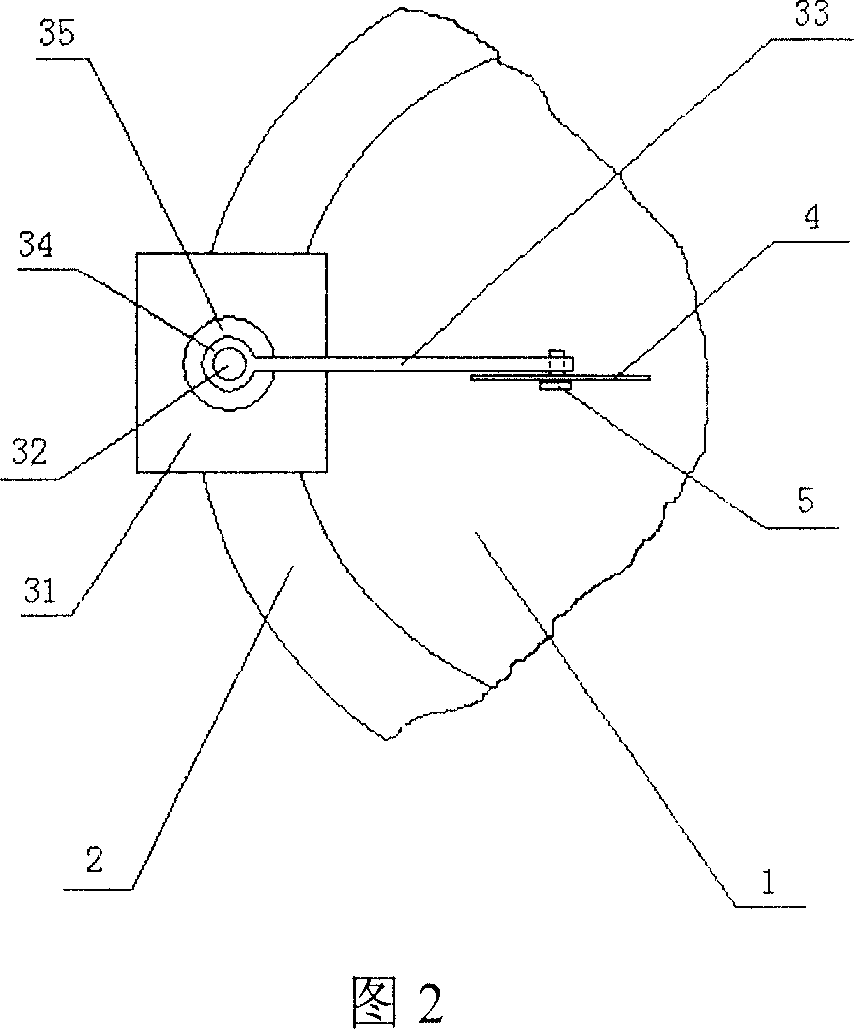

[0020] As shown in Figure 1, before measuring, first determine the reference point at the lower edge of the large manhole on the furnace top according to the elevation, then fix the measuring bracket 3, and then refer to the furnace throat steel brick rotating support beam, align it with the furnace throat diameter direction and lock it , turn on the switch of the laser rangefinder 5 on the dial 4, rotate its angle, and scan from one end of the furnace wall 2 to the other end. Simultaneously record the distance measured by the laser rangefinder 5 and the corresponding angle on the dial. After the measurement of one diameter direction is completed, the measuring device can be switched to the next reference point and the data of different diameter directions can be measured in the same way. It is also possible to adjust to the next position for measurement by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com