Zirconium dioxide loaded microsphere type silica gel superstrong acid catalyst

A technology of catalysts and small balls, applied in the direction of physical/chemical process catalysts, catalyst activation/preparation, preparation of organic compounds, etc., can solve problems such as the trouble of separating catalysts, and achieve the effects of protecting the environment, increasing the reaction temperature, and increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

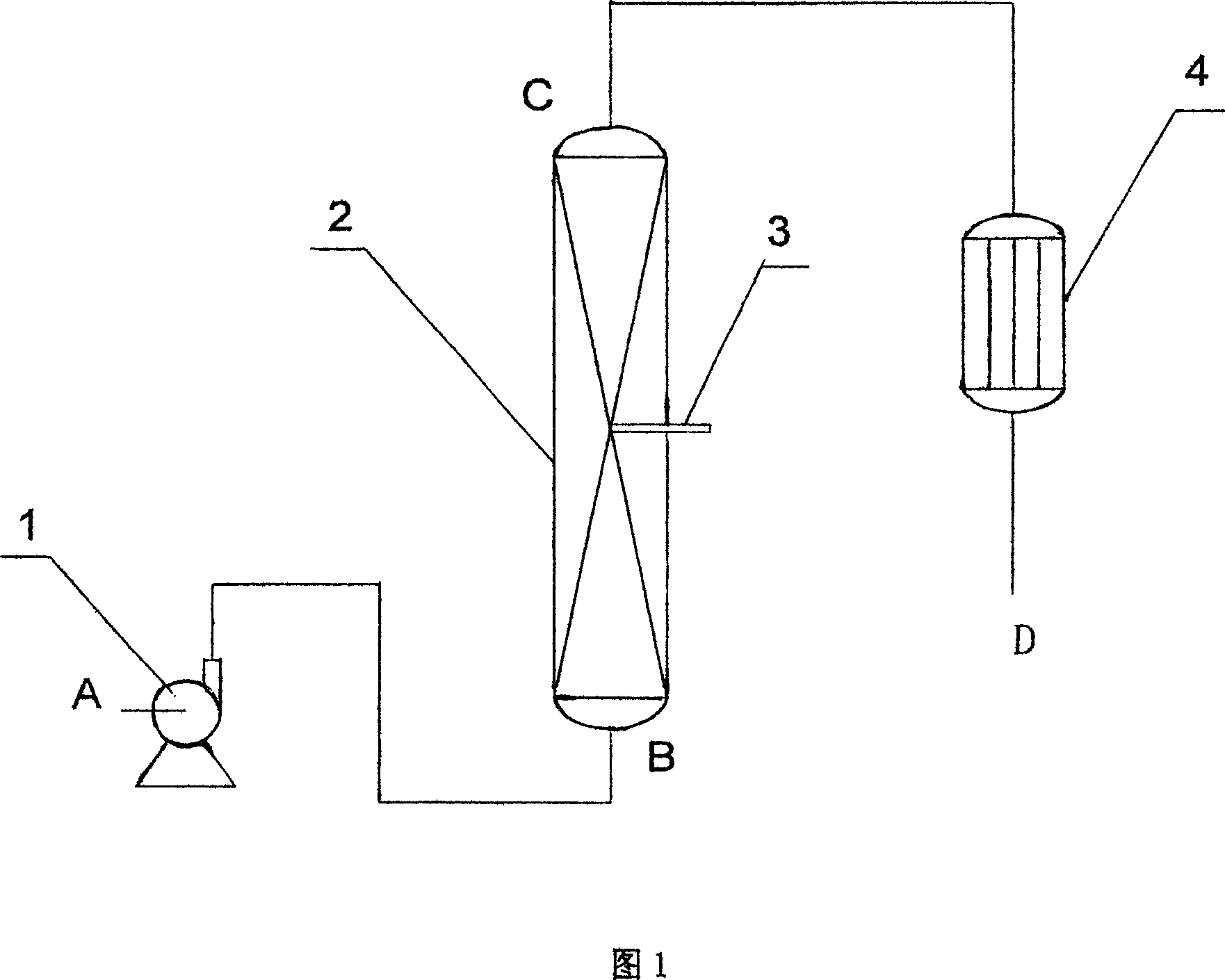

Image

Examples

Embodiment 1

[0032] Vacuum-dry the macroporous finished silica gel pellets and put them into a buffer solution composed of C.P grade glacial acetic acid, C.P grade ammonium acetate and pure water for hole expansion. The pH value of the buffer solution is equal to 4.9-5.1. The buffer solution and silica gel pellets The volume ratio is 2:1. Under nitrogen bubbling, keep warm at 45°C. After 72 hours, filter out the silica gel pellets and dry them in vacuum. (2) Put the dried silica gel pellets into the zirconium tetrachloride solution. The solution is prepared by mixing C.P grade concentrated hydrochloric acid and C.P grade zirconium tetrachloride, and their weight ratio is 2.0:1. Stand at normal temperature and pressure for 70 hours, stir once an hour, and filter out the pellets. (3) Put the filtered pellets into ammonia water with a concentration of 1.0-2.0% by weight, add ice cream to the ammonia water, and the volume ratio of ammonia water to pellets is 10:1. Then add concentrated ammo...

Embodiment 2

[0034] Except that the volume ratio of buffer solution and silica gel pellets in step (1) is 1.87: 1, the weight ratio of C.P grade concentrated hydrochloric acid to C.P grade zirconium tetrachloride is 1.5: 1 in step (2), and the sulfuric acid in step (4) Except that the solution concentration is 1.5N, all the other reaction steps and reaction conditions are the same as in Example 1. As a result, the small spherical solid superacid catalyst has physical and chemical indicators: the acid strength Hammett function Pka value is -15.05, and the specific surface area is 160--190m 2 / g, the pore volume is 0.546cm 3 / g, the most likely pore diameter D is equal to 112.5 Ȧ, the particle size is 4.5-5.8mm, and the internal pressure strength (average value) is ≥6kg / particle.

Embodiment 3

[0036] Except that the volume ratio of buffer solution and silica gel pellets in step (1) is 1.95: 1, the weight ratio of C.P grade concentrated hydrochloric acid and C.P grade zirconium tetrachloride in step (2) is 1.8: 1, and sulfuric acid in step (4) Except that the solution concentration is 1.5N, all the other reaction steps and reaction conditions are the same as in Example 1. As a result, the small spherical solid superacid catalyst has physical and chemical indicators: the acid strength Hammett function Pka value is -15.05, and the specific surface area is 160--190m 2 / g, the pore volume is 0.560cm 3 / g, the most likely pore diameter D is equal to 118.5 Ȧ, the particle size is 4.5-5.8mm, and the internal pressure strength (average value) ≥ 6kg / particle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com