A filter of direct coupling triangle substrate integral waveguide cavity

A cavity filter and triangular base technology, applied in the field of filters, can solve the problems of high cost, bulky, difficult integration, etc., and achieve the effect of low cost, strong anti-interference ability, and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

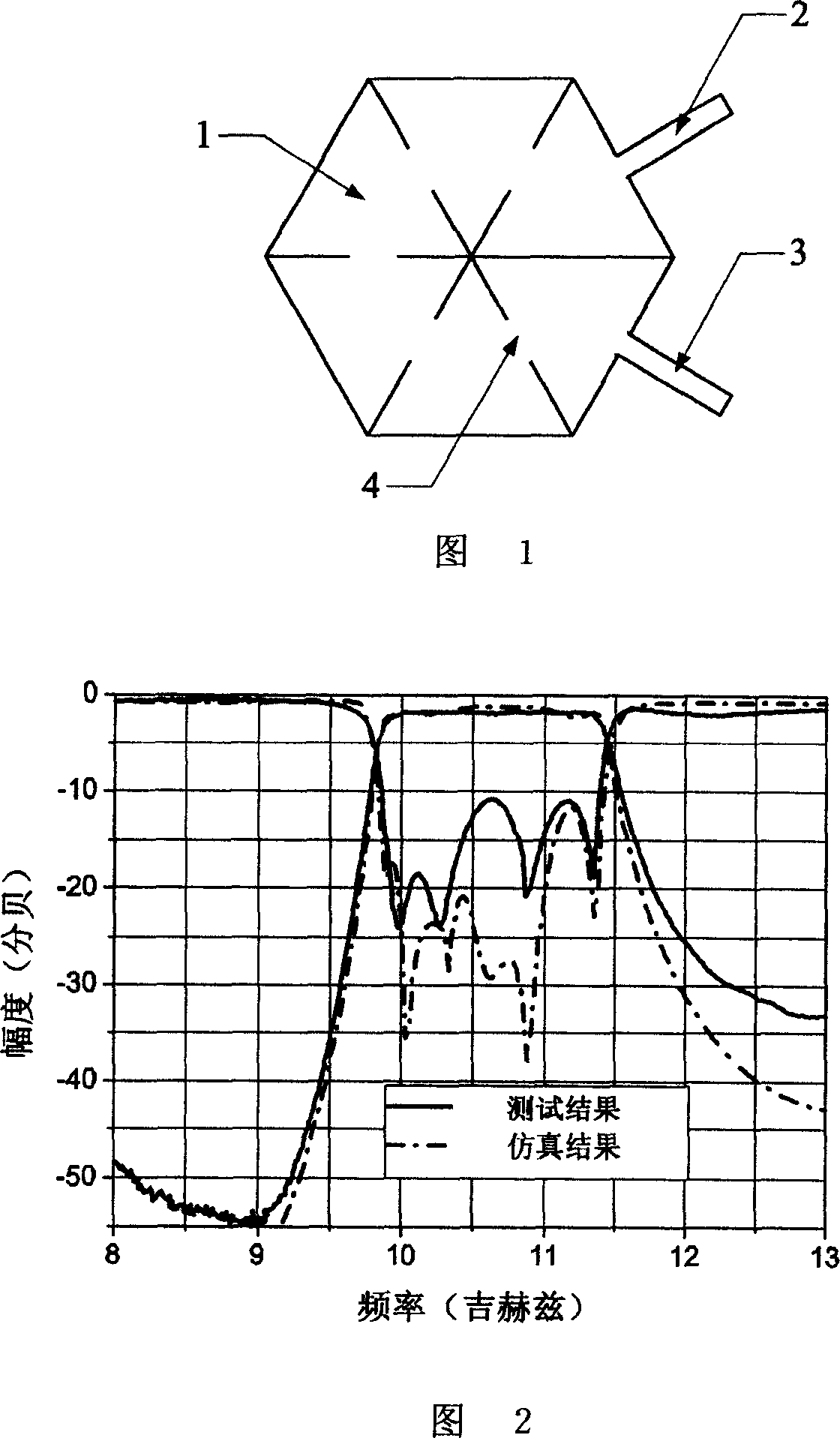

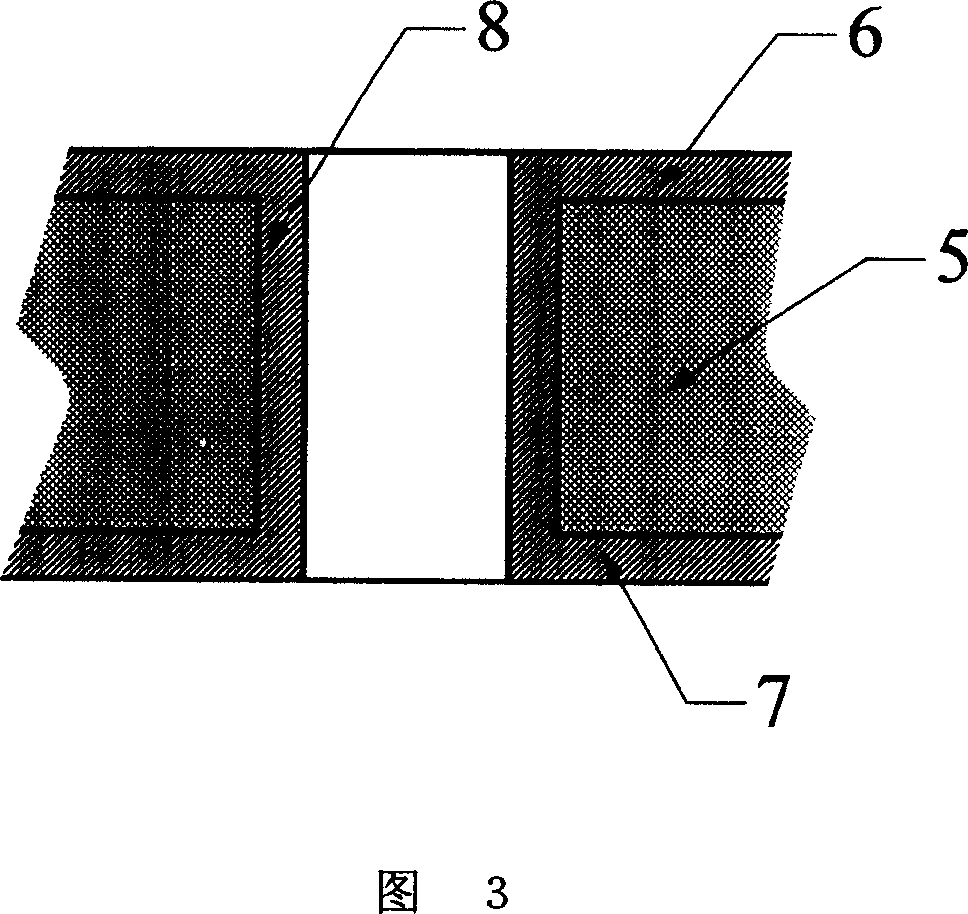

[0017] A direct-coupled triangular substrate integrated waveguide cavity filter, referring to Figure 1, includes isosceles triangular cavities 1, each isosceles triangular cavity 1 is arranged in sequence to form a regular polygon, wherein any two adjacent isosceles triangular cavities The bodies are the start cavity and the end cavity respectively. The input port 2 and the output port 3 are respectively provided on the start cavity and the end cavity, and a coupling is provided between the start cavity and its adjacent cavity. Window 4, a coupling window is provided between the end cavity and its adjacent cavity, a coupling window is provided between adjacent cavities and the adjacent cavity is located between the start cavity and the end cavity Among them, the above-mentioned isosceles triangular cavity is composed of metallized through holes on the dielectric substrate 5 covered with metal foils 6 and 7 on both sides, and the metallized through holes are arranged in an isosc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com