Method for measuring minute angle based on self-commix interference of laser and apparatus thereof

A self-mixing interference and micro-angle technology, applied in the field of laser measurement, can solve the problems of low measurement accuracy and complex devices of the self-collimation method, and achieve the effect of simple structure and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

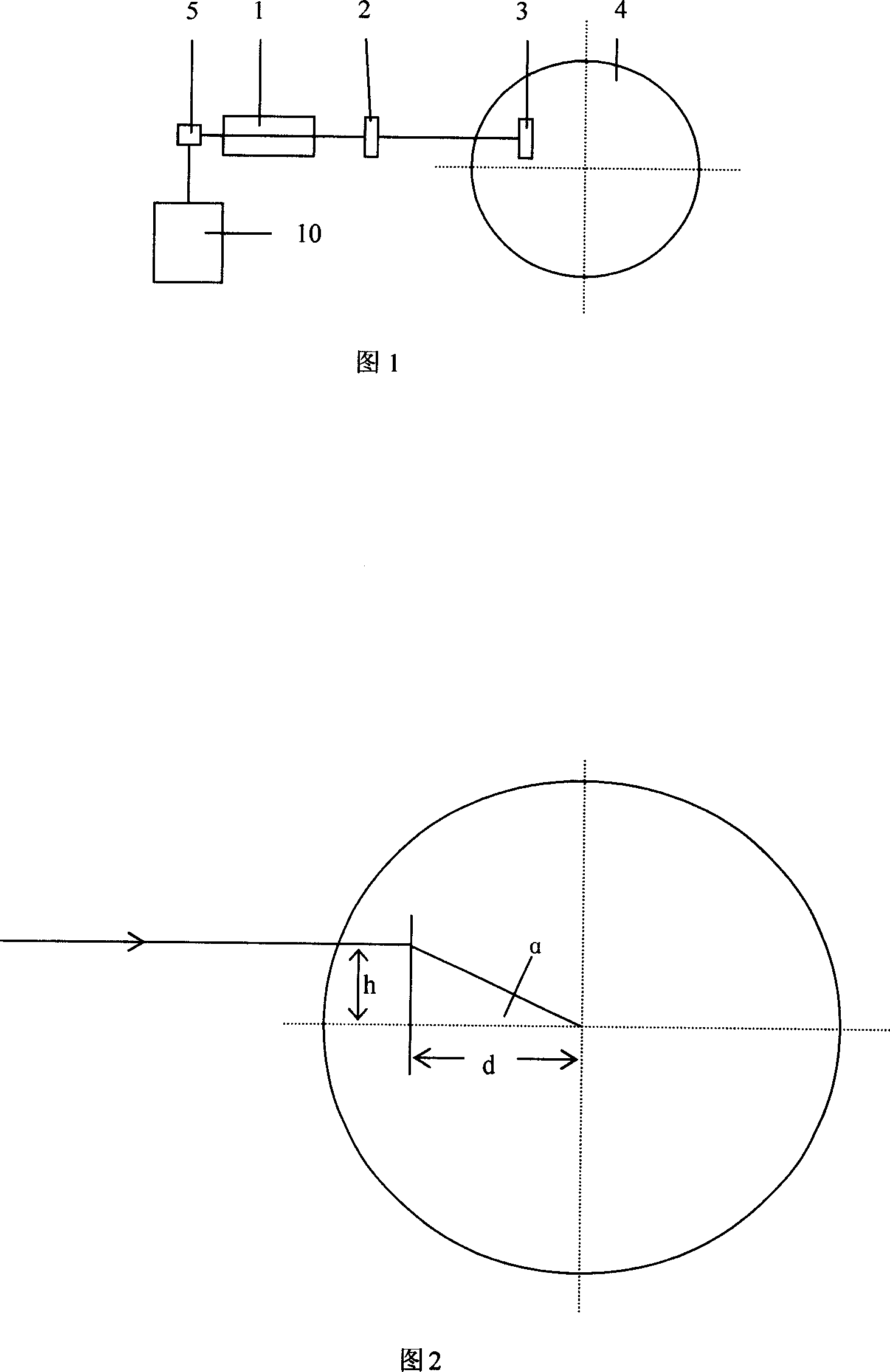

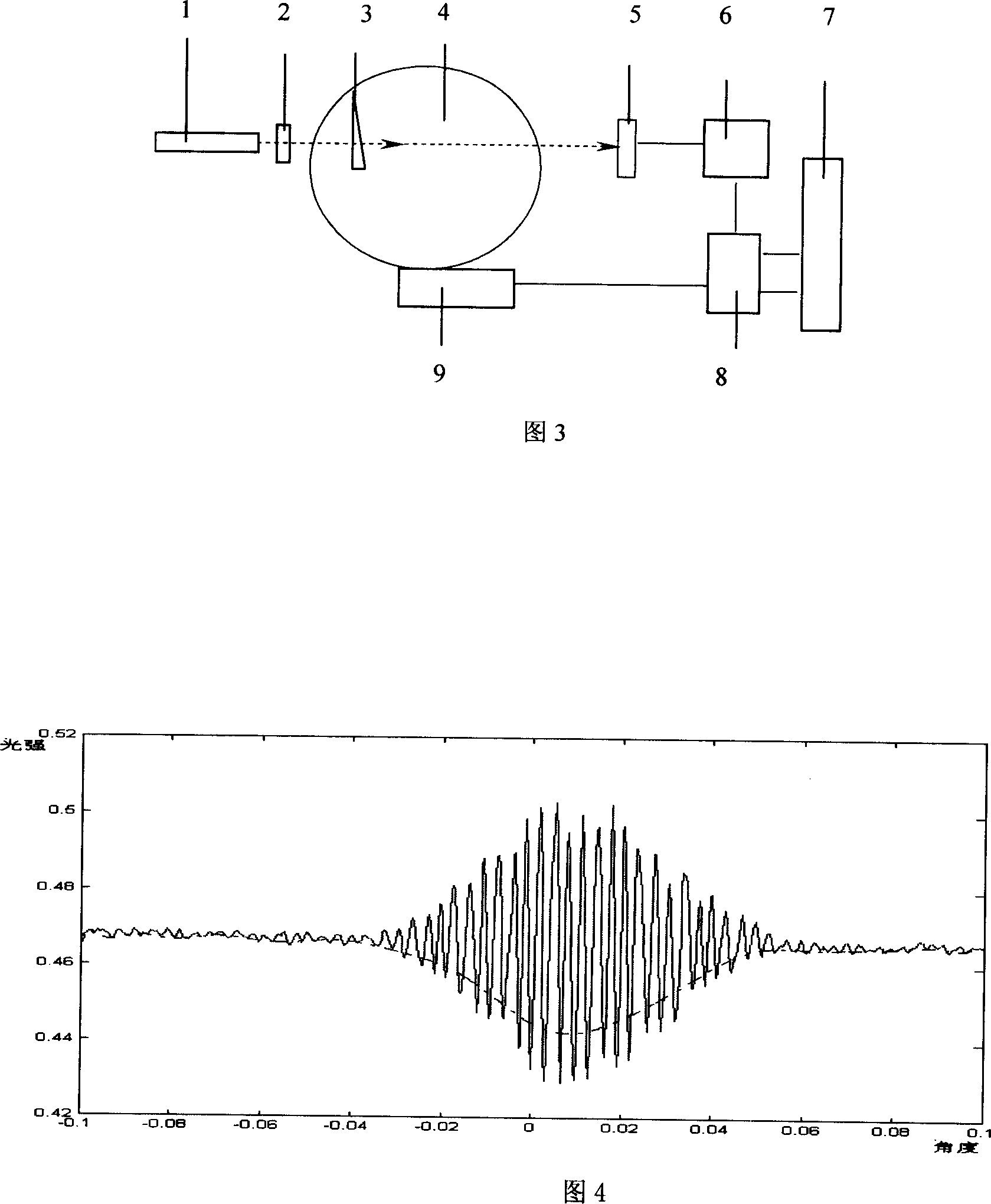

[0029] As shown in Figure 3, the laser 1 adopts a helium-neon laser with a cavity length of 250 millimeters and an output power of 3 milliwatts; a transparent optical wedge reflector 3 is fixed on the rotary table 4, and adopting the optical wedge as the reflector can avoid the distortion of the plane reflector. The reflected light from the two surfaces is fed back into the laser cavity at the same time, so that only the reflected light from one surface can be fed back into the laser cavity. The reflectivity of the transparent wedge mirror is about 4%, forming a weak feedback mode; the laser beam deviates from the measured object by 4 The distance d=0.75mm from the angular rotation center, and the distance h=1.5cm from the wedge reflector 3 to the angular rotation center. A silicon photocell 5 is used to detect the light beam energy passing through the optical wedge. The silicon photocell 5 converts the optical signal into an electrical signal and then amplifies it through the ...

Embodiment 2

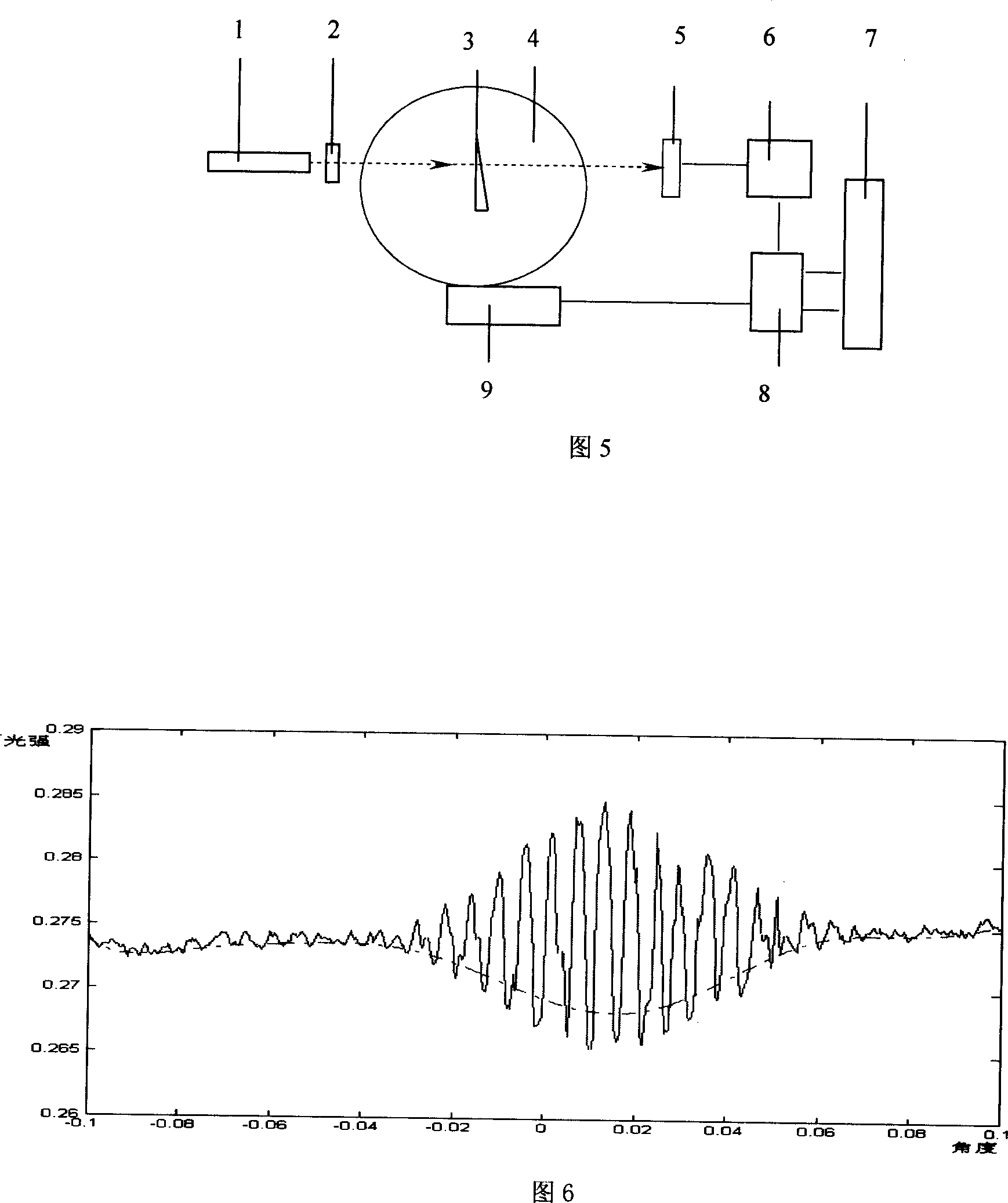

[0032] Among Fig. 5, difference with embodiment 1 is that, laser device 1 adopts the semiconductor laser device that output power is 5 milliwatts, and the distance h=3mm that laser beam deviates from measured object 4 angular rotation centers, the reflective surface of optical wedge reflector 3 The plane on which passes through the angular rotation center.

[0033] Fig. 6 is a curve of measured optical power changing with angle. In the figure, the dotted line is the curve fitting line, through which the maximum amplitude of the interference fringes can be found, and the corresponding angle here is taken as the zero reference angle for angle measurement. Through the pre-calibrated angle value corresponding to each change of a fringe period and the fringe subdivision technology, the measurement of the small rotation angle of the measured object can be realized by using Figure 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com