Production method of nano-carbon tube

A technology of carbon nanotubes and a growth method, which is applied in the field of carbon nanotube growth, can solve problems such as inability to grow fine-structure carbon nanotubes, cumbersome manufacturing process, and large catalyst layer particles, and achieve shortened total reaction time, increased solubility, and improved manufacturing process. simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

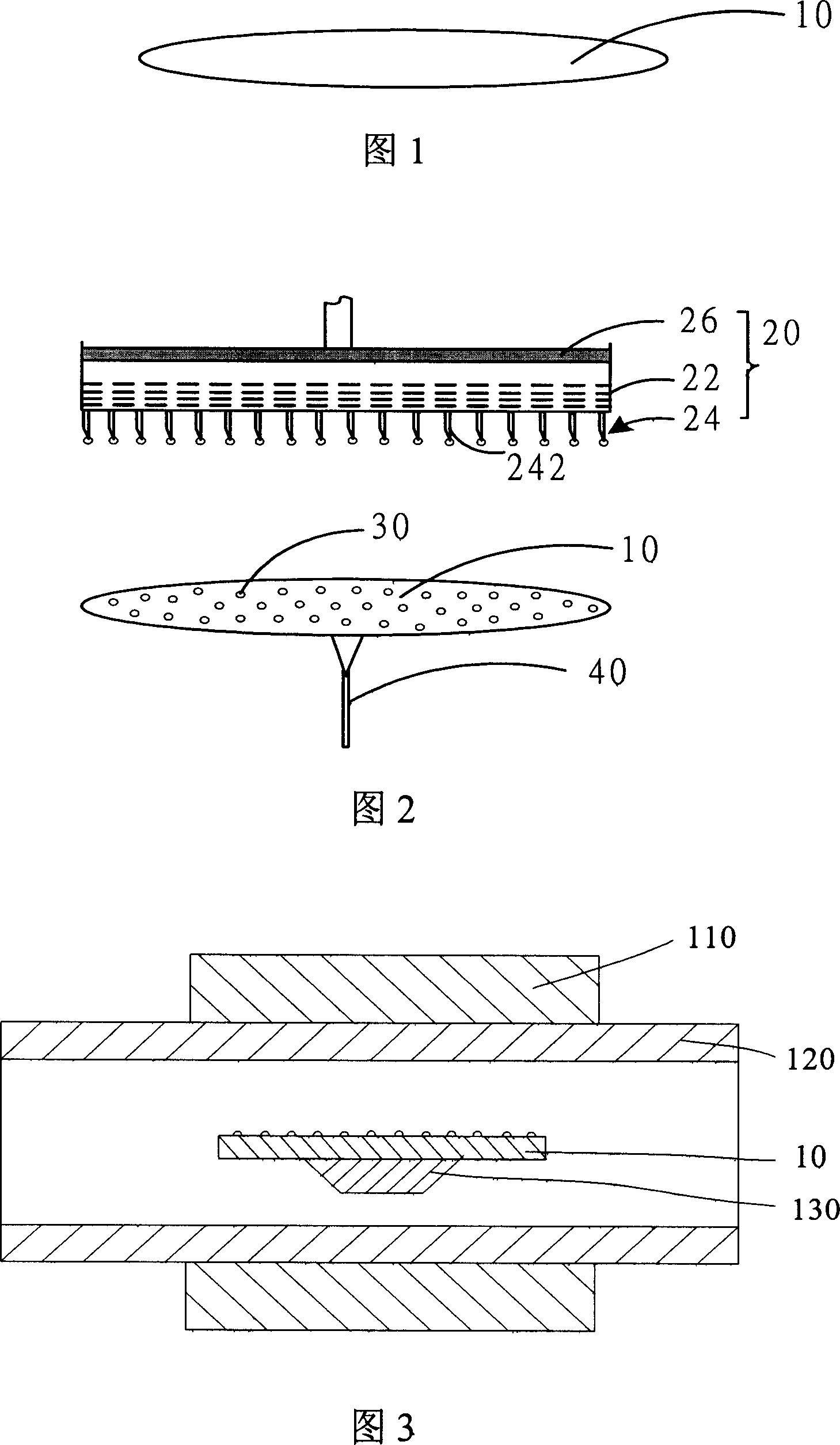

[0015] The growth method of described carbon nanotubes comprises the steps:

[0016] The first step is to provide a substrate 10, as shown in Figure 1, which can be glass, silicon wafer or quartz wafer, etc.;

[0017] The second step is to prepare a nano-catalyst solution with a certain viscosity.

[0018] The catalyst of this embodiment can be nano-scale metal iron, cobalt, nickel, or alloys of metal iron, cobalt or nickel, or oxides of metal iron, cobalt or nickel, and the nano-catalyst is prepared in a solution to facilitate the subsequent formation of a catalyst layer.

[0019] Give an example below to illustrate the preparation method of the nano-catalyst solution with a certain viscosity:

[0020] 8.6 g FeCl 2 Tetrahydrate with 23.5 g FeCl 3 The hexahydrate was dissolved in distilled water. Then add 20-50 milliliters of ammonia water, heat the aqueous solution to 80°C under vigorous stirring, and obtain magnetite (Fe 3 o 4 ) nanoparticles precipitate.

[0021] A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com