Method for belt pre-conditioning, method for pelletizing urea and pelletizing plant

A technology of granulation and pretreatment, which is applied to urea compound fertilizer, granulation on endless conveyor belts, nitrogen fertilizer, etc. It can solve the problems of high equipment and energy costs, and achieve the effect of good washing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

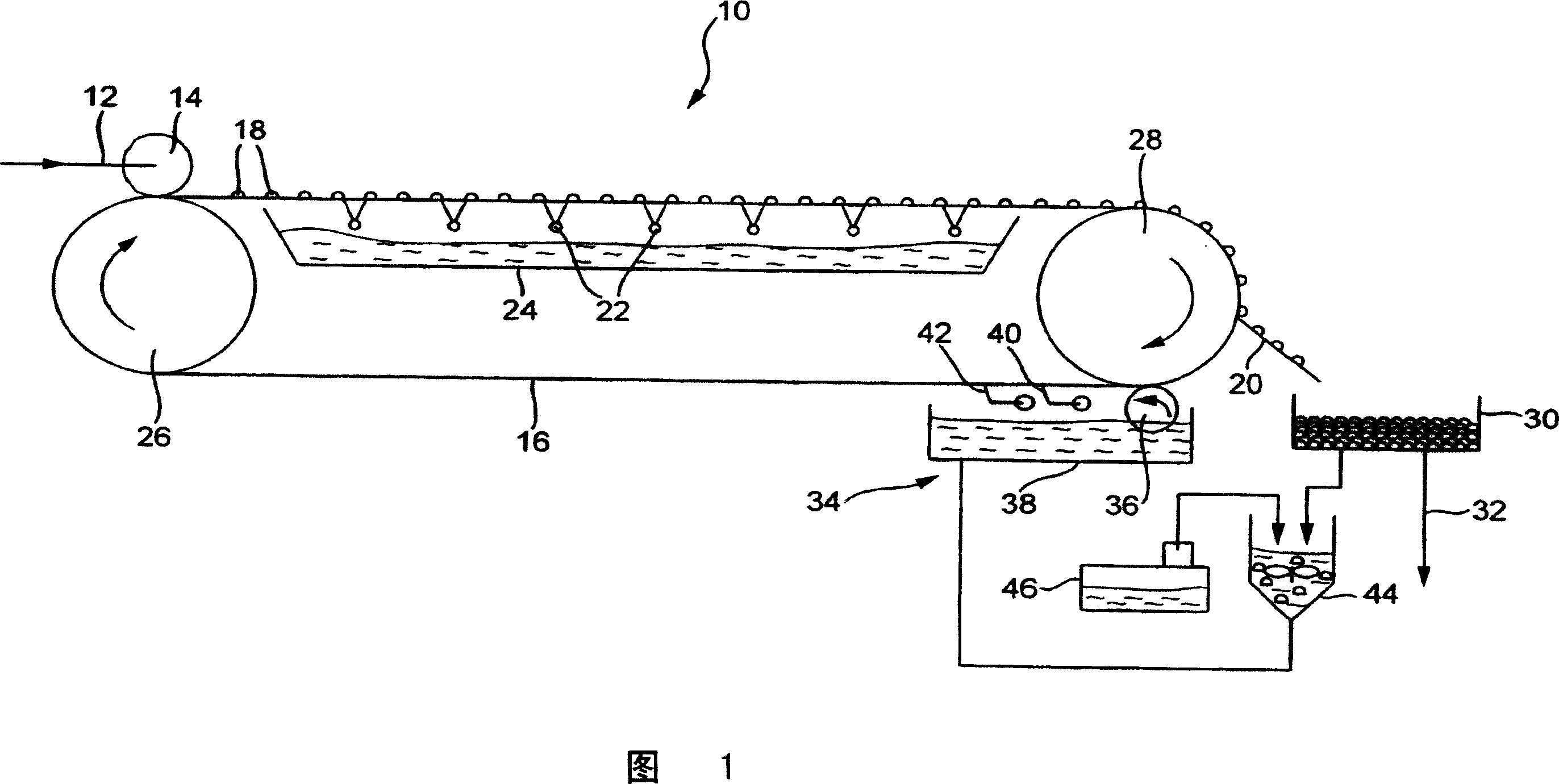

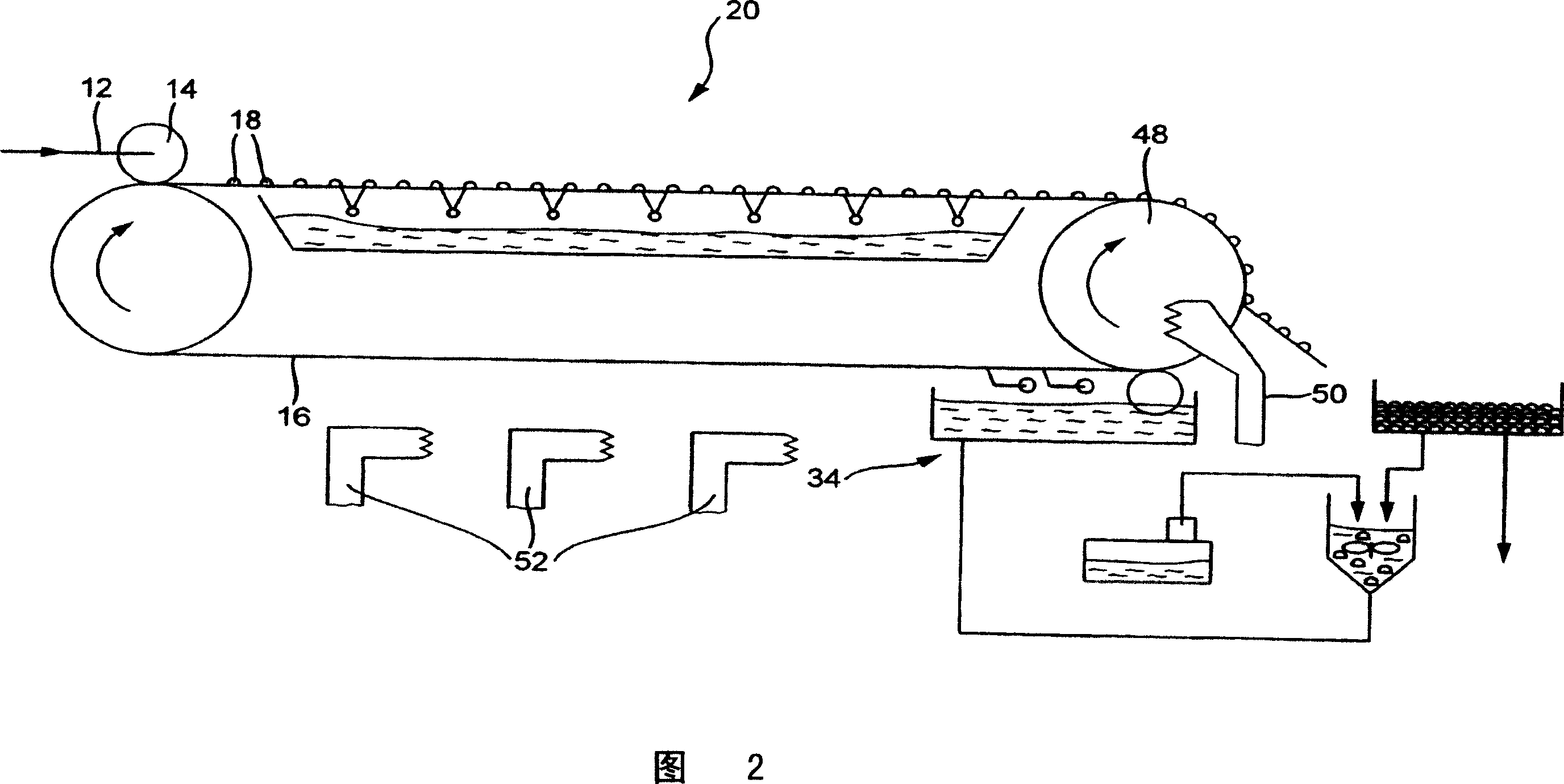

[0040] In the schematic diagram of FIG. 1 a pelletizing plant 10 for pelletizing urea is shown. Urea is a meltable product, but has hygroscopic properties not only in the solidified state but also in the molten form. Urea pellets are used, for example, in the manufacture of fertilizers.

[0041] On conventional granulation plants with a surrounding steel belt, due to the hygroscopic properties of urea there is the danger that the molten urea dripping on the steel belt in the form of droplets absorbs moisture and the droplets will become flat. As a result, large cake-shaped granules are formed after solidification, which in extreme cases can even be displaced with adjacent droplets. Large cake-shaped droplets are very unfavorable for storage and reprocessing of urea.

[0042] A urea melt is fed to a granulation plant 10 in a known manner via a supply line 12 to a so-called rotary shaper 14 . The rotary shaper 14 consists of a fixed heated inner shell and an outer tube equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com