Scriber for controlling pressure by magnetic force

A scriber, pressure technology, applied in the direction of manufacturing tools, glass manufacturing equipment, planer/slotting machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

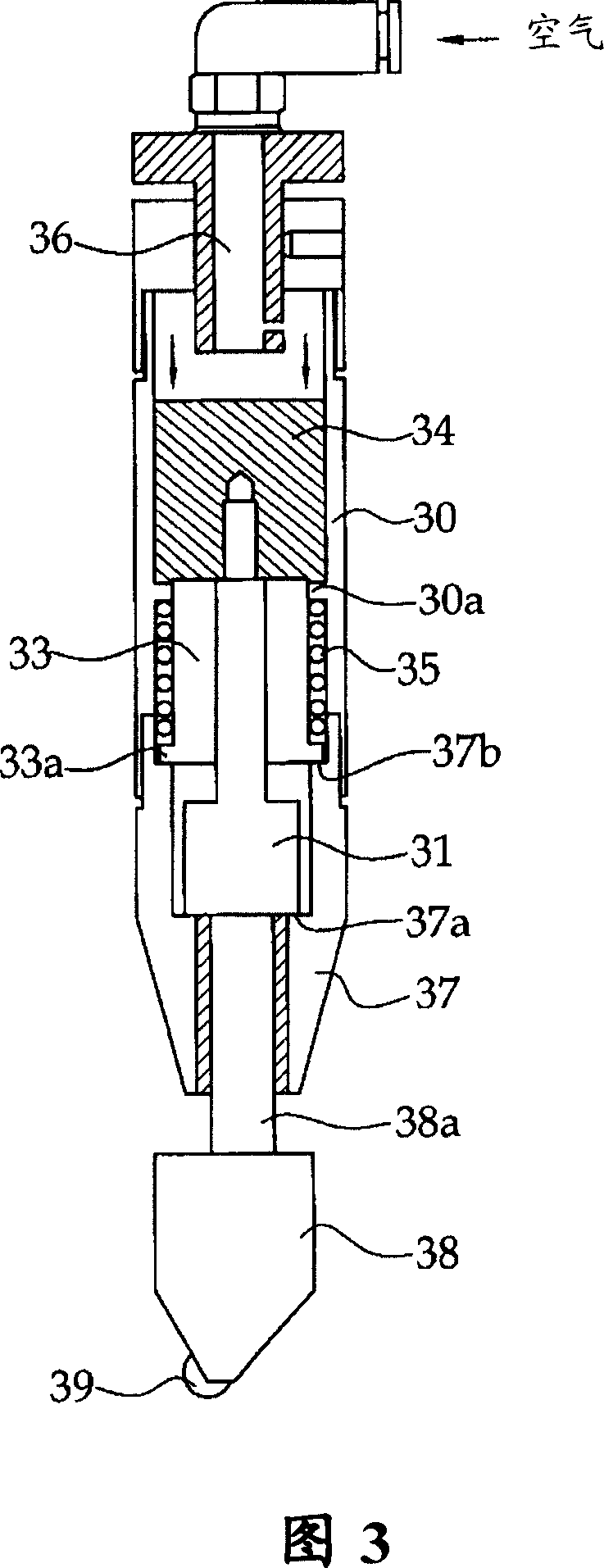

[0058] As shown in FIG. 4 , the scribe using magnetic force to control pressure according to the first embodiment of the present invention includes: a head 40 including a pressure applying magnet 46 for a permanent magnet; a movable head 50 including a permanent The pressure of the magnet receives the magnet 52, the movable head 50 is movably connected to the lower end of the head 40; and the wheel holder 56, which is mounted at the movable head 50.

[0059] Head 40 includes housing end 43 , pressure device 44 , and housing 42 . The housing end 43 is formed at the lower end of the head 40 and is connected to the movable head 50 so that the movable head 50 is movable within a certain range. The pressure device 44 has a hollow so that the pressure applying magnet 46 can be positioned. The housing 42 has a hollow to accommodate the pressure device 44 .

[0060] The movable head 50 includes a wheel holder connecting portion 54 , a pressure receiving portion shaft 53 , and a pres...

no. 2 example

[0066] As shown in FIG. 5 , the scriber using magnetic force to control pressure according to the second embodiment of the present invention includes: a head 60 including a pressure applying magnet 66 for the electromagnet; a movable head 70 including a permanent The pressure of the magnet receives the magnet 70, the movable head 70 is movably connected to the lower end of the head 60; and the wheel holder 76, which is mounted at the movable head 70.

[0067] Head 60 includes housing end 63 , pressure device 64 , and housing 62 . The housing end 63 is formed at the lower end of the head 60 and is connected to the movable head 70 so that the movable head 70 is movable within a certain range. The pressure device 64 has a hollow so that the pressure applying magnet 66 can be positioned. The housing 62 has a hollow portion so that the pressure device 64 can be accommodated.

[0068] An electromagnet as the pressure applying magnet 66 is electrically connected to a power supply d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com