A measuring device and measuring method for the effective impact radius of a gas drainage borehole

A technology that affects radius and gas extraction. It is used in mining devices, gas discharge, safety devices, etc. It can solve the problems of inability to track and observe, no, and pressure inconsistencies, and achieve high test success rate, high measurement accuracy, and accurate assurance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

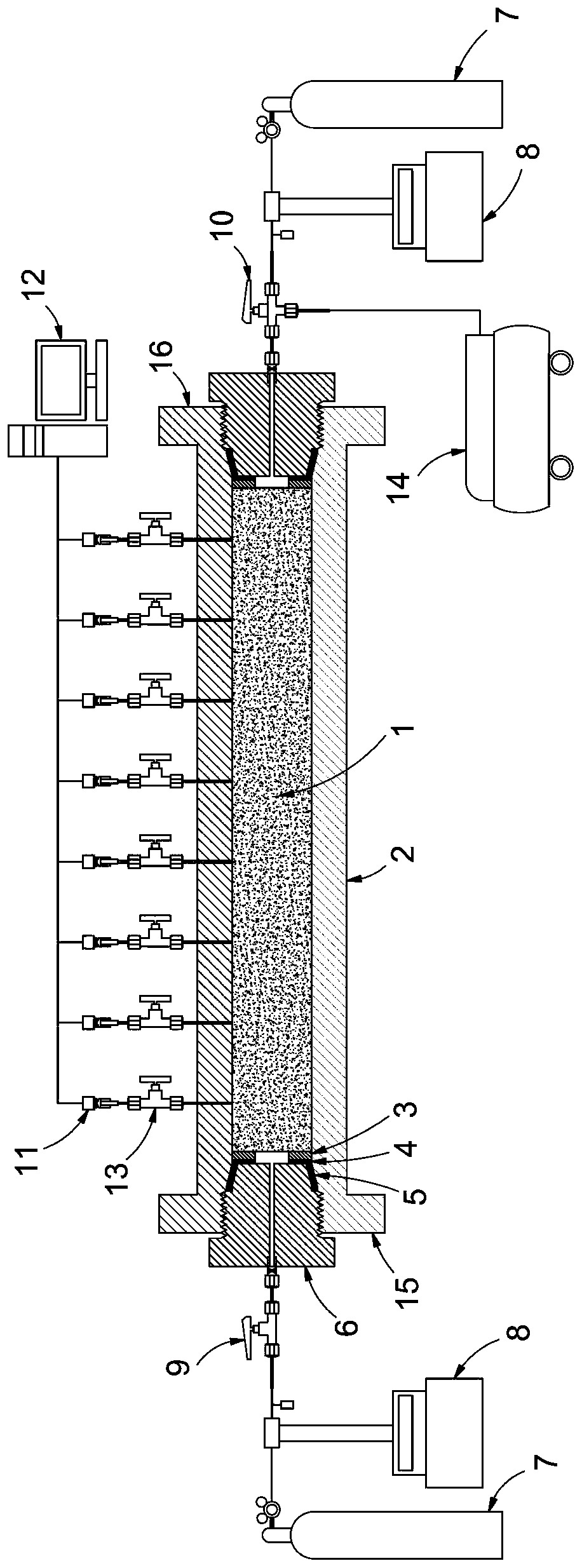

[0033]The coal core holder includes a cylinder body 2, a plug 6 and an annular gasket assembly; the cylinder body 2 is a cylindrical structure, and the two ends of the cylindrical structure along its axial direction are the pressure stabilizing end 15 and the negative pressure end 16. The outer surface of the cylindrical structure is provided with a plurality of uniformly distributed pressure measuring ports along the axial direction, and the pressure measuring ports penetrate the wall of the cylindrical structure along the radial direction of the cylindrical structure. In terms of accuracy, the number of pressure measuring ports is not less than 5; the plug 6 is set in two pieces, and the two pieces of plug 6 are respectively sealed and fixed on the pressure stabilizing end 15 and the negative pressure end 16. In the axial direction, there is a gas inlet and outlet channel through the plug 6; the number of annular gasket assemblies corresponding to the plug 6 is set to two set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com