System for heating spray head in spray-painting device

A technology for heating systems and inkjet printers, applied in typewriters, printing, etc., can solve the problems of increased electromagnetic interference, high system failure rate, and small diameter of heating pipes, and achieve the effects of strong automatic control, simple system structure, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

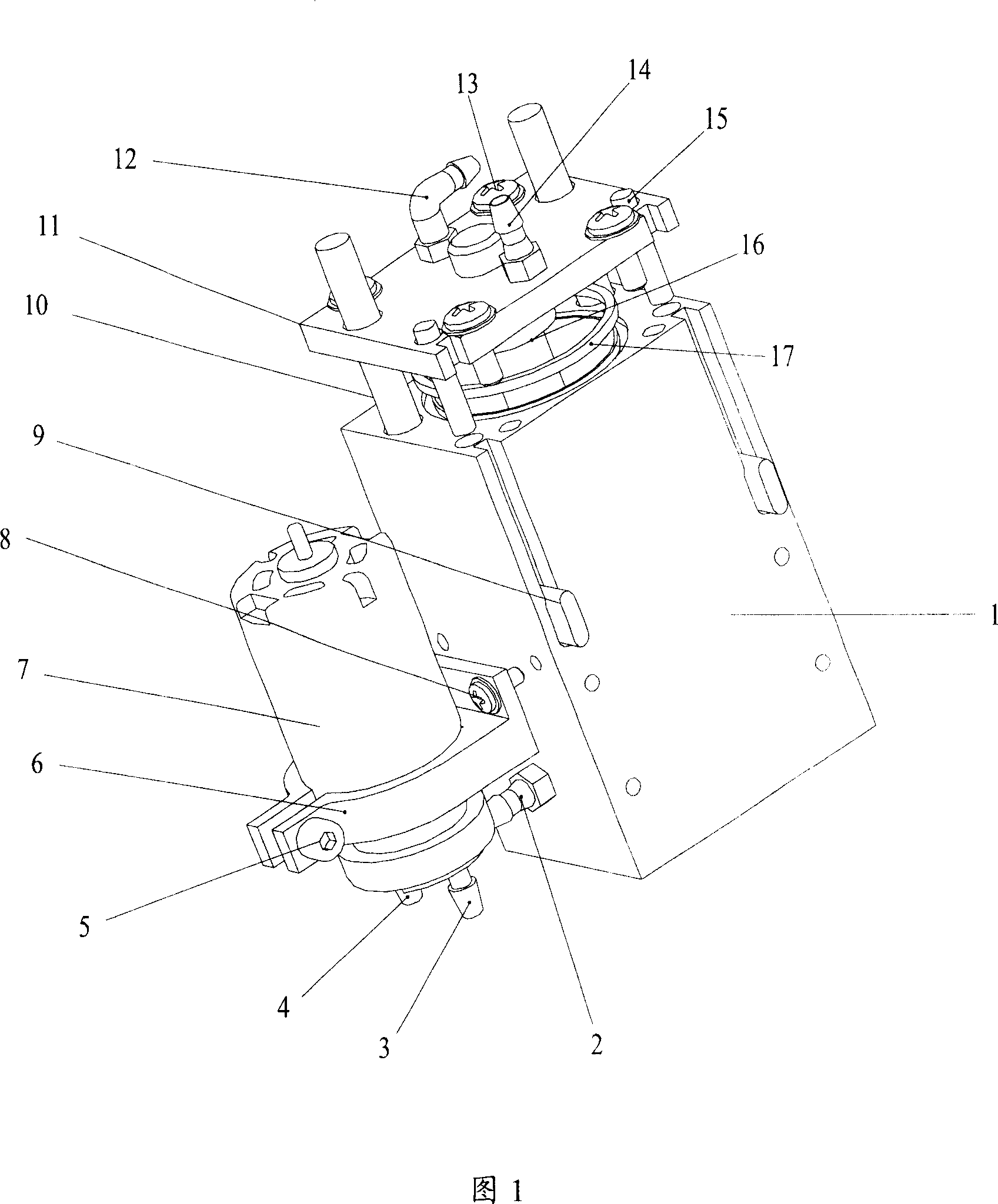

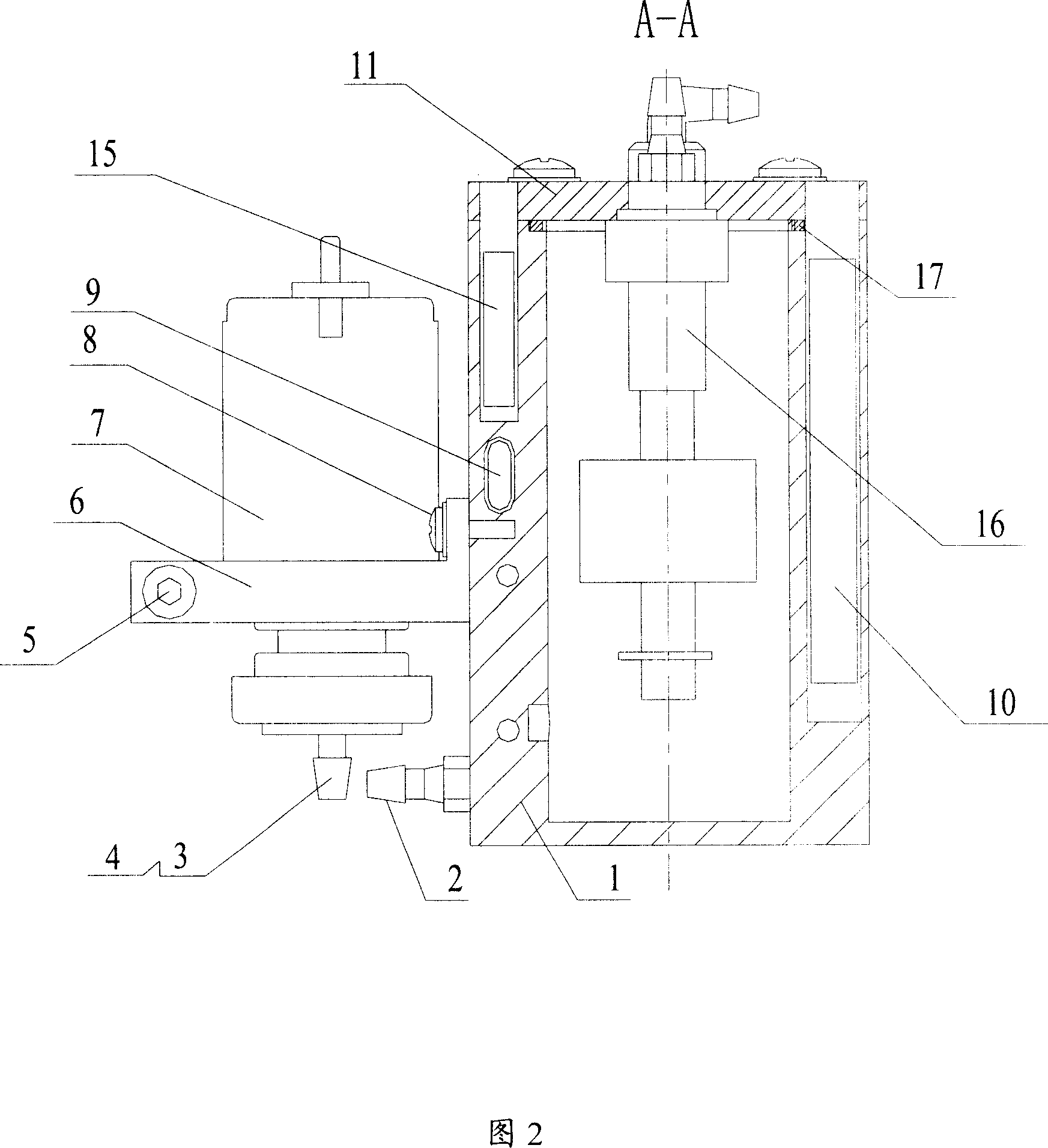

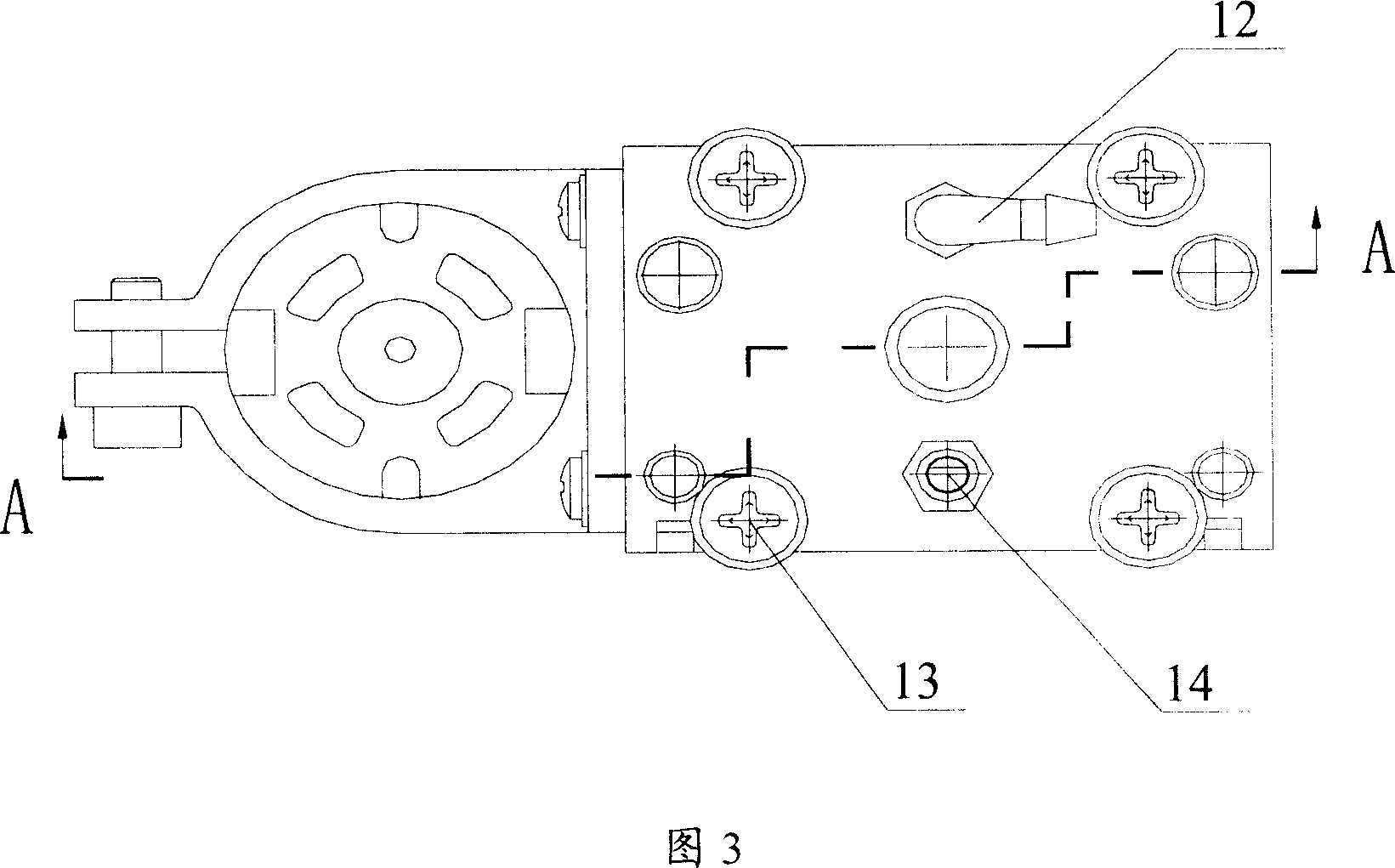

[0038] Aiming at the problems of poor heating effect, complicated wiring and high cost in the existing electric heating system, the present invention provides a nozzle heating system for inkjet printers. The heating system is extended from the electric heating system, but adopts a The heating system is very different.

[0039] The heating method of the nozzle heating system provided by the present invention is: the water heated to a certain temperature is pumped into the water pipe installed on the nozzle of the inkjet printer through the rotary vane pump, and the nozzle is heated by circulating water with a certain temperature, instead of the prior art In each nozzle, heating pipes, thermistors and overheating protectors are installed to directly heat the nozzles; among them, the nozzles of the inkjet printers themselves are equipped with nozzle water pipes.

[0040] It can be seen from the above analysis that the key point to realize the present invention is to design a devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com