Gas supplying unit and substrate processing apparatus

A substrate processing device and gas supply technology, applied in the direction of spraying devices, spraying devices, electrical components, etc., can solve the problems of heat generation affecting the temperature detection value, unstable temperature control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

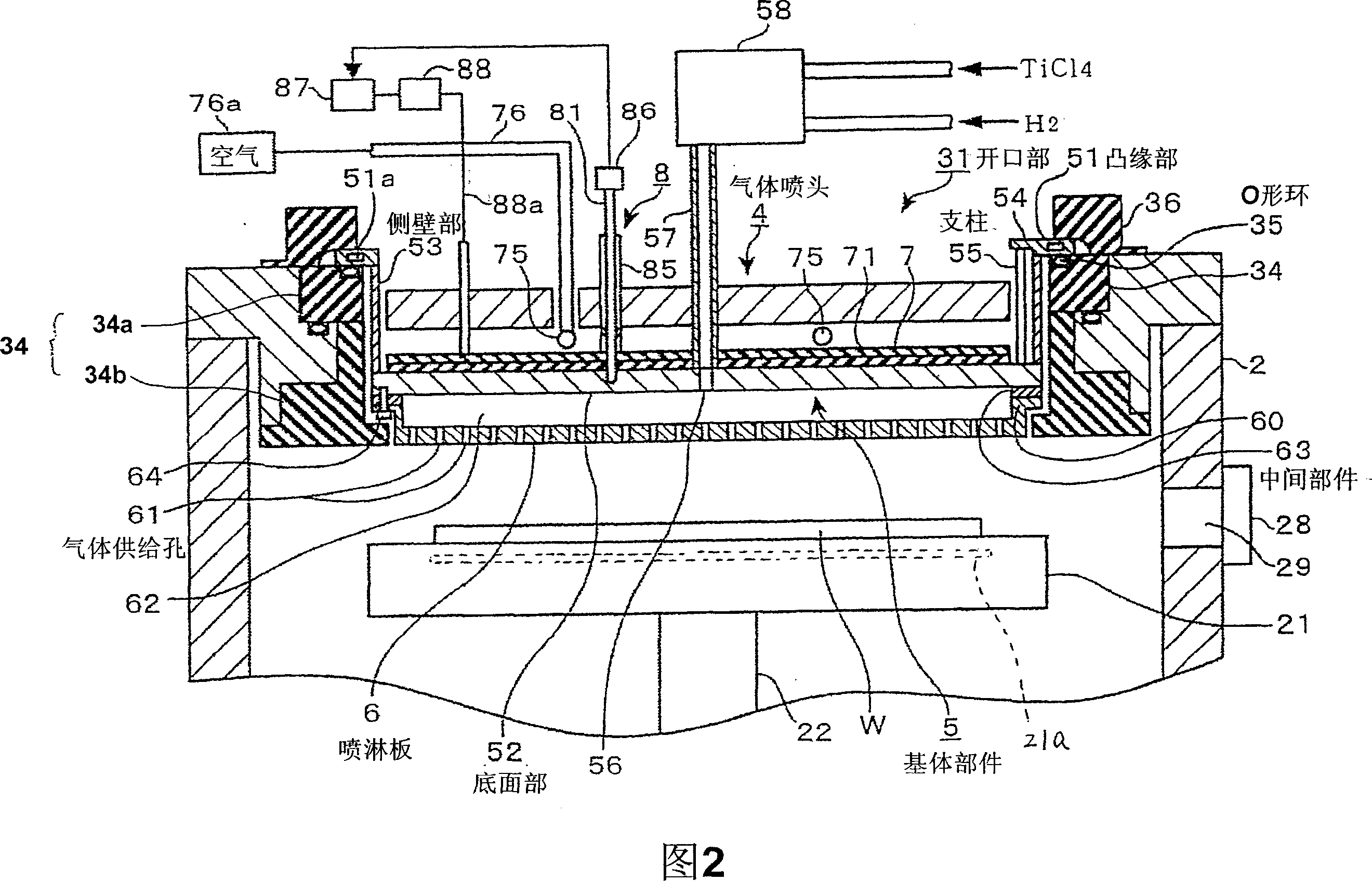

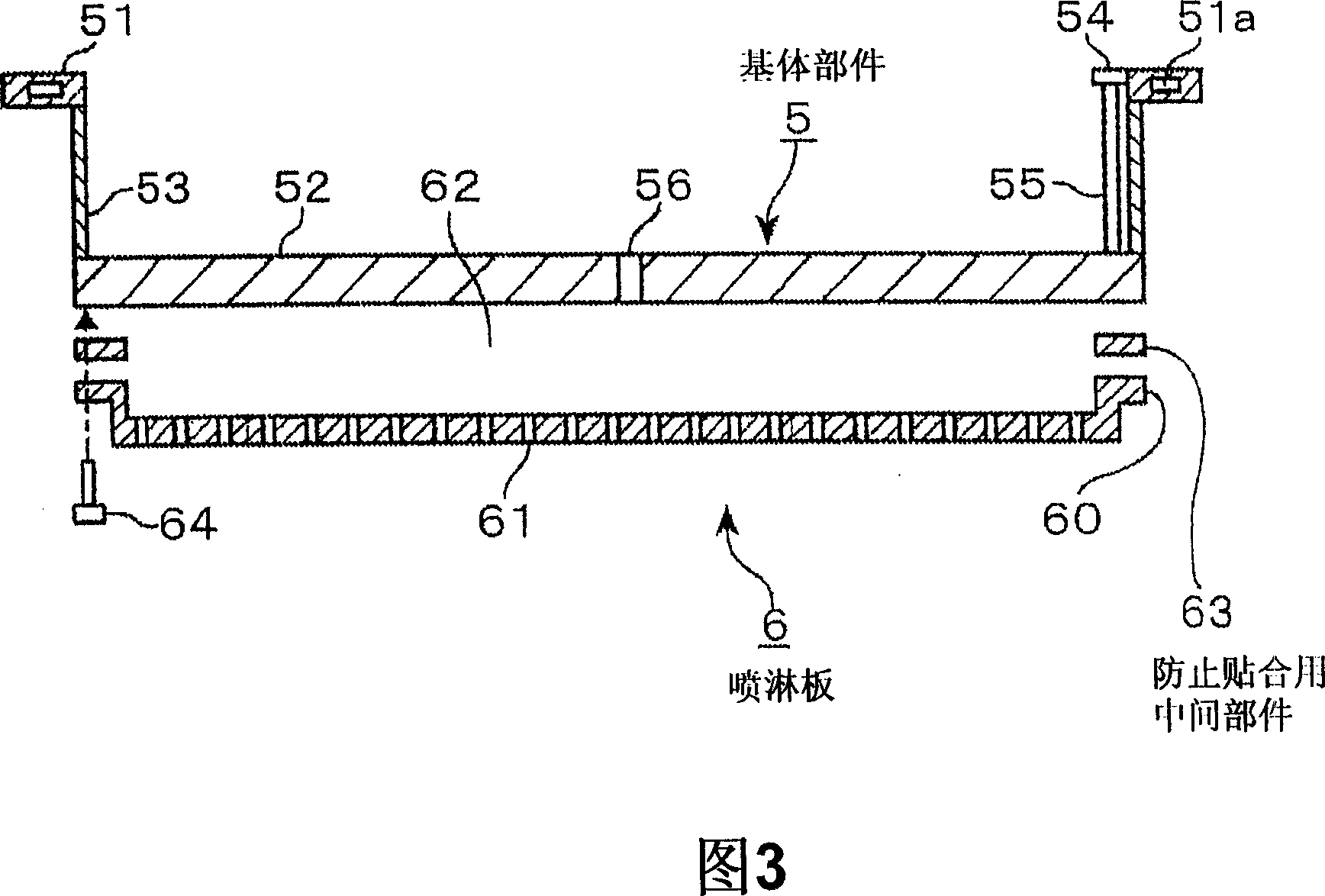

[0032] An embodiment in which the gas supply device of the present invention is incorporated in a film formation apparatus for film formation by plasma CVD will be described. First, the overall structure of the film forming apparatus will be briefly described based on the schematic diagram of FIG. 1 . In FIG. 1, 2 is a processing container as a vacuum chamber made of, for example, aluminum, and the processing container 2 is formed to be composed of an upper large-diameter cylindrical portion 2a and a lower small-diameter cylindrical portion 2b in communication with each other. The so-called mushroom shape is provided with an unillustrated heating mechanism for heating the inner wall. In the processing container 2, there is provided a stage 21 constituting a substrate mounting table for horizontally mounting, for example, a semiconductor wafer (hereinafter referred to as a wafer) W as a substrate. The stage 21 is supported by a support member 22 at the bottom of the small-diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com