Superhigh strength high conduction block pure copper material and preparation method

A high-conductivity, ultra-high-strength technology, applied in the field of bulk high-density nano-twinned metal pure copper and its preparation, achieves the effects of simple preparation method, excellent conductivity and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

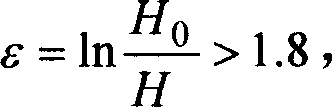

[0027] Using high-speed deformation technology to prepare high-strength, high-conductivity bulk high-density nano-twinned pure copper materials;

[0028] Equipment: Pneumatic high-speed deformation equipment;

[0029] Deformation strain rate: 1×10 2 the s -1 ;

[0030] Deformation strain: deformation 2.3 (5 deformations, each deformation of the first four deformations is 0.5, and the fifth deformation is 0.3);

[0031] Deformation temperature: -196°C;

[0032] Pure copper material: purity 99.95%, annealed at 700°C for 3 hours, grain size 150-200 microns.

[0033] A bulk high-density nano-sized twinned pure copper material is prepared, as shown in Figure 1. The main feature of its microstructure is bundle-shaped high-density nano-mechanical twins, with an average twin layer thickness of 30-50 nanometers and a length of 200-800 nanometers. The twin density is about 3×10 7 m 2 / m 3 . There are high-density dislocations in both the matrix and the twins, and the dislocatio...

Embodiment 2

[0035] Using high-speed deformation technology to prepare high-strength, high-conductivity bulk high-density nano-twinned pure copper materials;

[0036] Equipment: Pneumatic high-speed deformation equipment;

[0037] Deformation strain rate: 1×10 3 the s -1 ;

[0038] Deformation strain: deformation 2 (4 deformations, each deformation 0.5);

[0039] Deformation temperature: -100°C;

[0040] Pure copper material: purity 99.95%, annealed at 700°C for 3 hours, grain size 150-200 microns.

[0041] A bulk high-density nano-sized twinned pure copper material is prepared, as shown in Figure 1. The main feature of its microstructure is bundled high-density nano-mechanical twins, with an average twin layer thickness of 30-50 nanometers and a length of 100-600 nanometers. The twin density is about 1.5×10 7 m 2 / m 3 . There are high-density dislocations in both the matrix and the twins, and the dislocation density is 1.3×10 15 . Using a strain rate of 6 x 10 -3 the s -1 A ten...

Embodiment 3

[0043] Using high-speed deformation technology to prepare high-strength, high-conductivity bulk high-density nano-twinned pure copper materials;

[0044] Equipment: Pneumatic high-speed deformation equipment;

[0045] Deformation strain rate: 1×10 4 the s -1 ;

[0046] Deformation strain: deformation 2.5 (5 deformations, each deformation 0.5);

[0047] Deformation temperature: -20°C;

[0048] Pure copper material: purity 99.95%, annealed at 700°C for 3 hours, grain size 150-200 microns.

[0049] A bulk high-density nano-sized twinned pure copper material is prepared, as shown in Figure 1. The main feature of its microstructure is bundle-shaped high-density nano-mechanical twins, with an average twin layer thickness of 30-50 nanometers and a length of 200-800 nanometers. The twin density is about 1.5×10 7 m 2 / m 3 . There are high-density dislocations in both the matrix and the twins, and the dislocation density is 1×10 15 . Using a strain rate of 6 x 10 -3 the s -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deformation temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com