An organic field effect transistor and its manufacture method

A technology of transistors and organic fields, applied in the field of organic field effect transistors and their preparation, can solve the problems that the size and position of dispersed crystals cannot be artificially controlled, the mechanical properties of organic crystals are poor, and the use of ultrasonic dispersion is limited, so as to avoid damage and simple equipment , to avoid the effects of radiation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

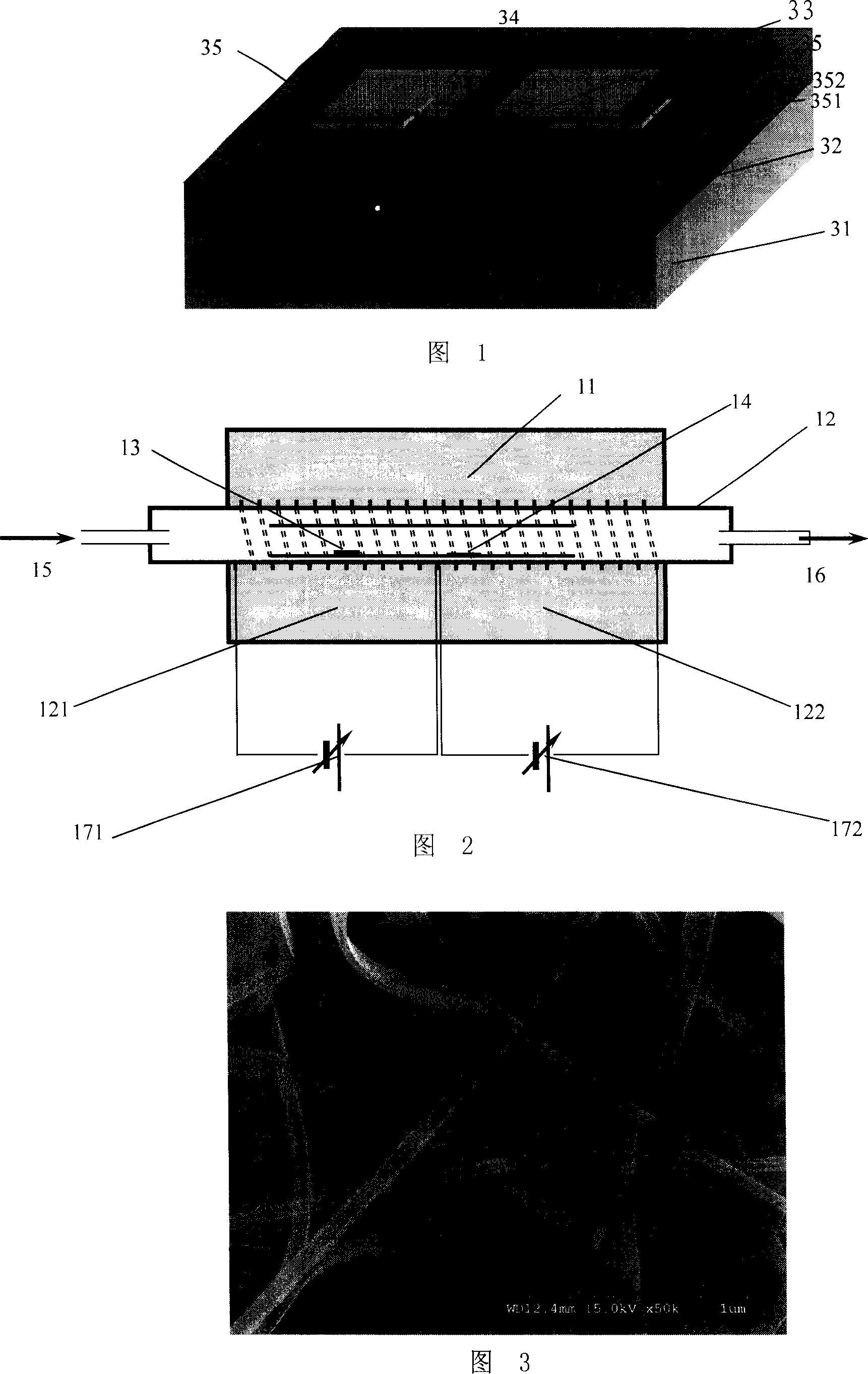

[0027] The structural representation of the field effect transistor of the present invention is as shown in Figure 1: two electrodes 35 (made up of a titanium layer 351 with a thickness of 5 nanometers and a gold layer 352 with a thickness of 70 nanometers) are laid on a substrate 31 with an insulating layer 32 in advance Above, these two electrodes serve as the source and drain of the transistor respectively, and the substrate 31 is also the gate of the transistor; the organic semiconductor single crystal micro / nano material 33 is located between the two electrodes 35, and its two ends pass through two metal films 34 are connected to two electrodes respectively, and the distance between the two metal layers can be adjusted to an appropriate level; according to the requirements of the device, the two metal layers can choose the same or different metal elements, only need to ensure that the metal film and the organic semiconductor It only needs to form ohmic contact between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com