2D levelness measuring method and apparatus thereof

A technology for levelness measurement and displacement measurement, which is used in measuring devices, height/level measurement, measuring instruments, etc., and can solve the problems of inability to achieve two-dimensional levelness measurement, high excitation current stability, and small excitation frequency drift. Reliable data, increased refraction angle, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

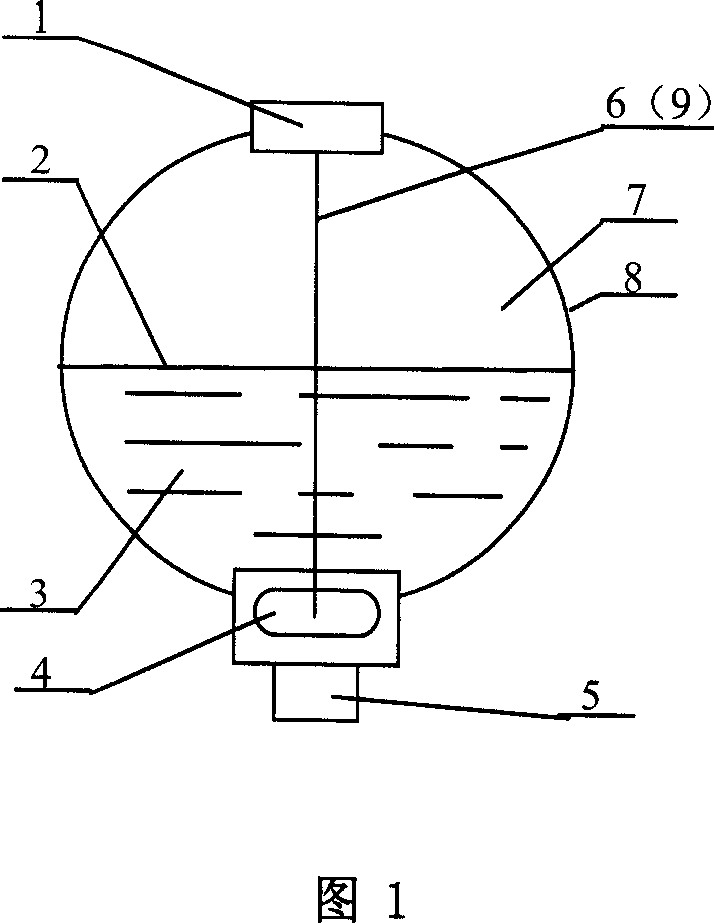

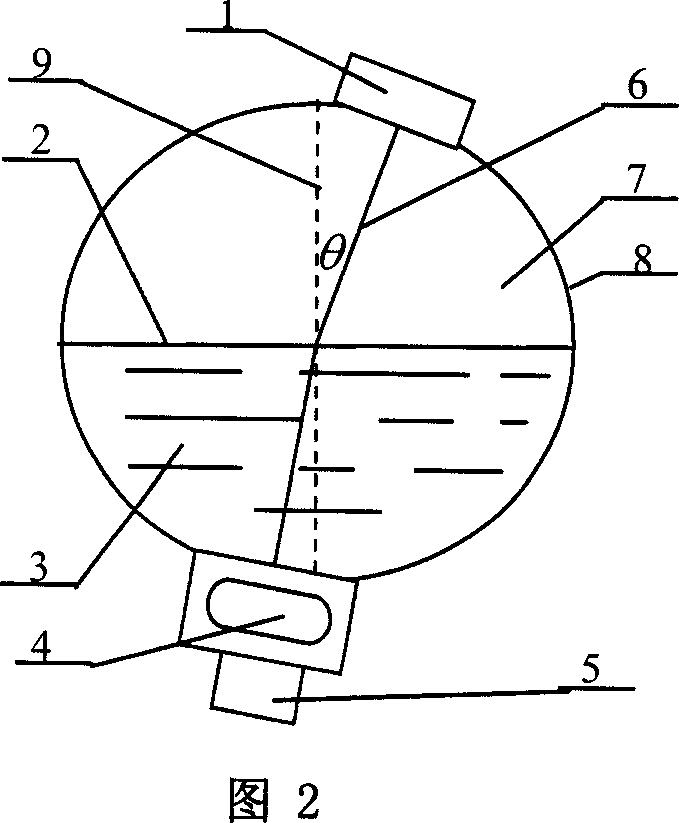

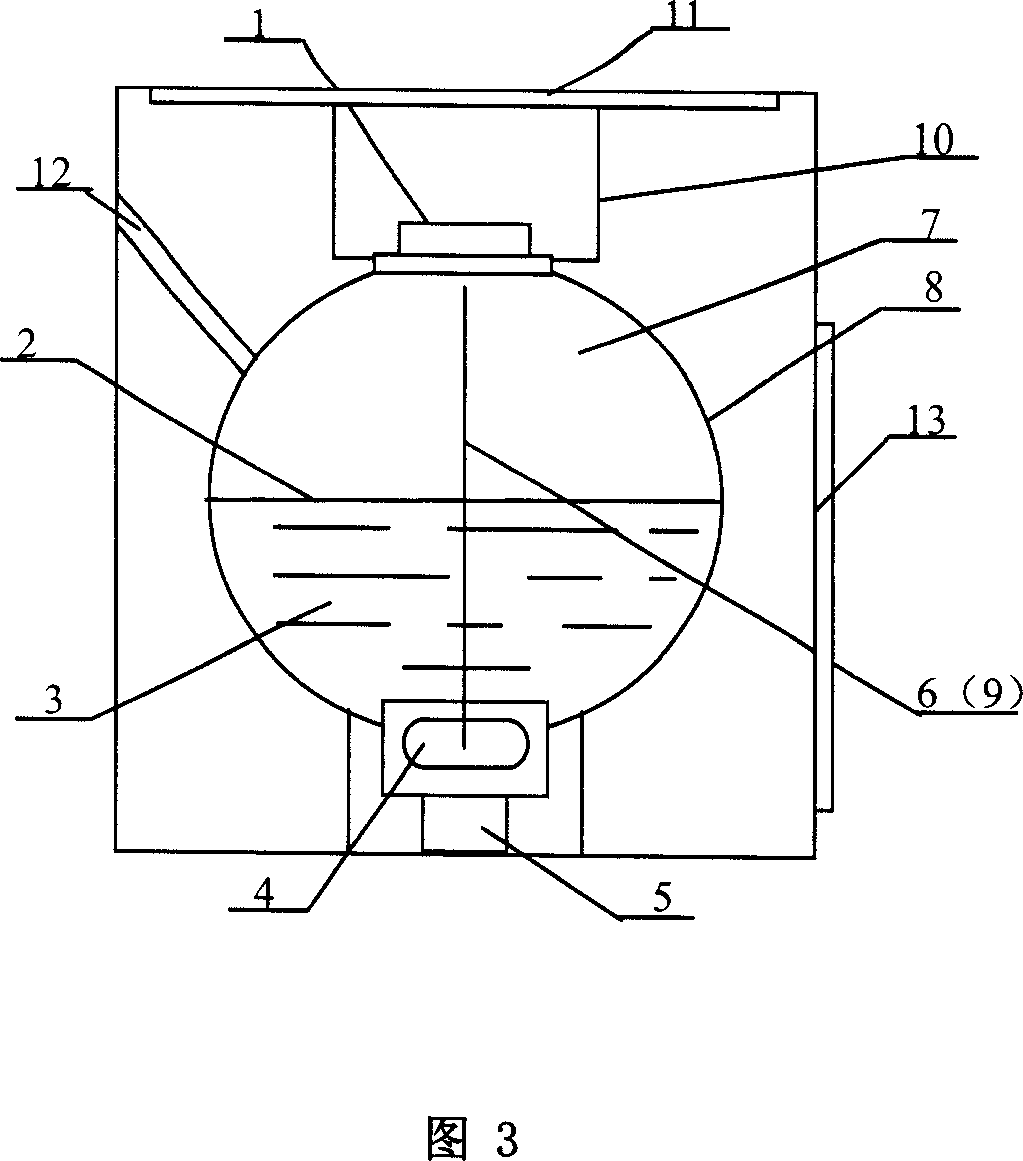

[0024] Referring to accompanying drawing 3, in this embodiment, a semiconductor laser diode 5 is used as the measuring light source, the power is <1 mW, and the laser beam is shaped and driven by the collimating optical lens 4 to form a pulsed modulation point light source with a diameter of 0.25 to 0.45 mm—— Measuring beam 6; a level sensor cavity 8 is injection-molded with black plastic, its inner cavity is a sphere with a diameter of 30mm, and its shape is a cylinder with a height of 50mm and a diameter of 40mm, and a liquid injection hole with a diameter of 1mm is designed on one side of the cylinder 12. A laser diode 5 and an optical lens 4 are installed on the bottom of the cylinder, and a spot displacement measuring device 1 is installed on the top of the cylinder. The displacement measuring device selected in this embodiment is a two-dimensional PSD position-sensitive sensor, and a four-operation anti-corrosion sensor is installed above it. Add a piece of protective gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com