Rod insertion pressure bearing type solar energy water heater

A solar water heater, pressure-bearing technology, applied in the direction of solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of water freezing in the tube, affecting heat transfer, and poor bathing comfort, so as to improve the heat conduction speed and avoid explosion. Tubes, the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

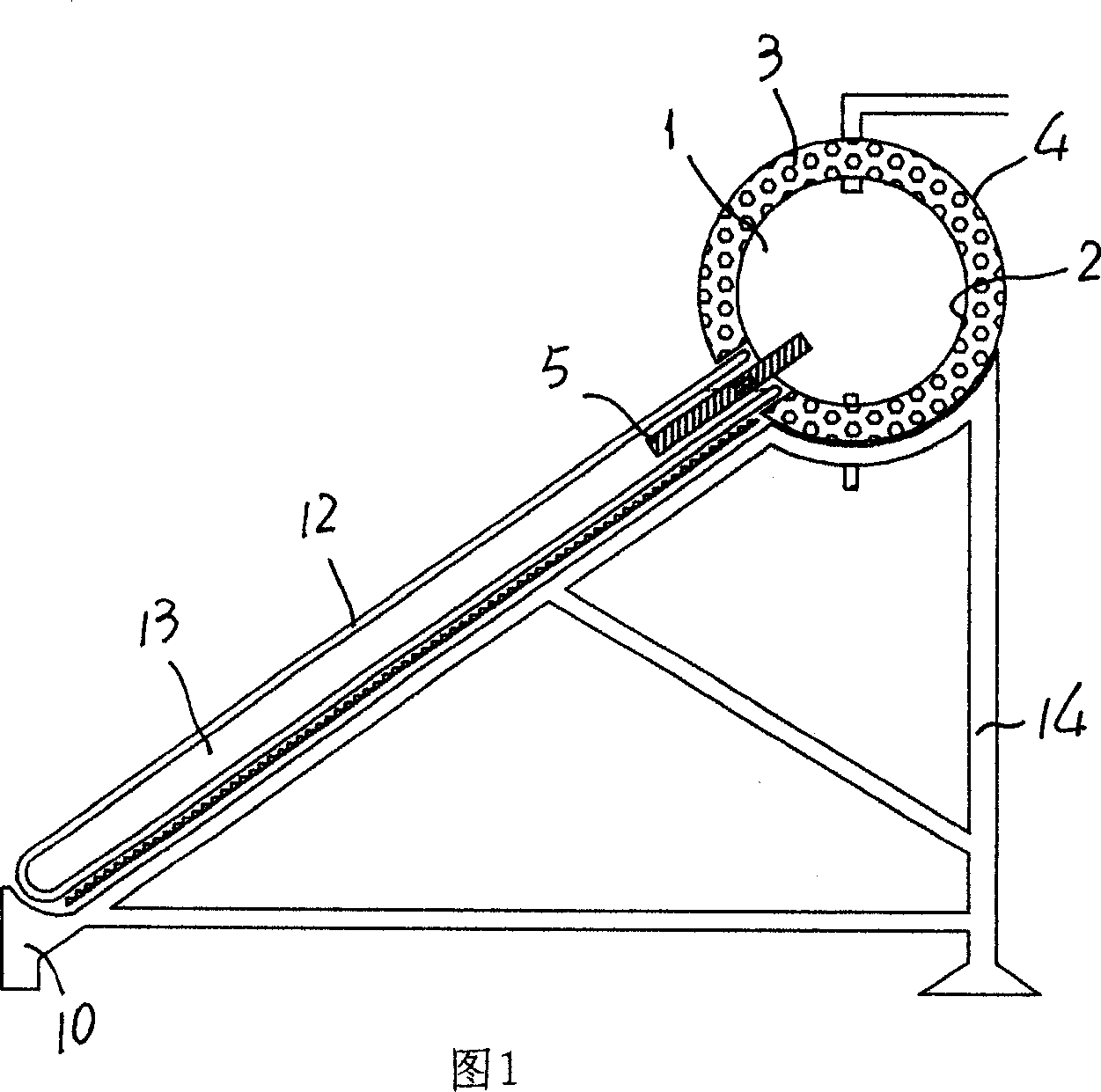

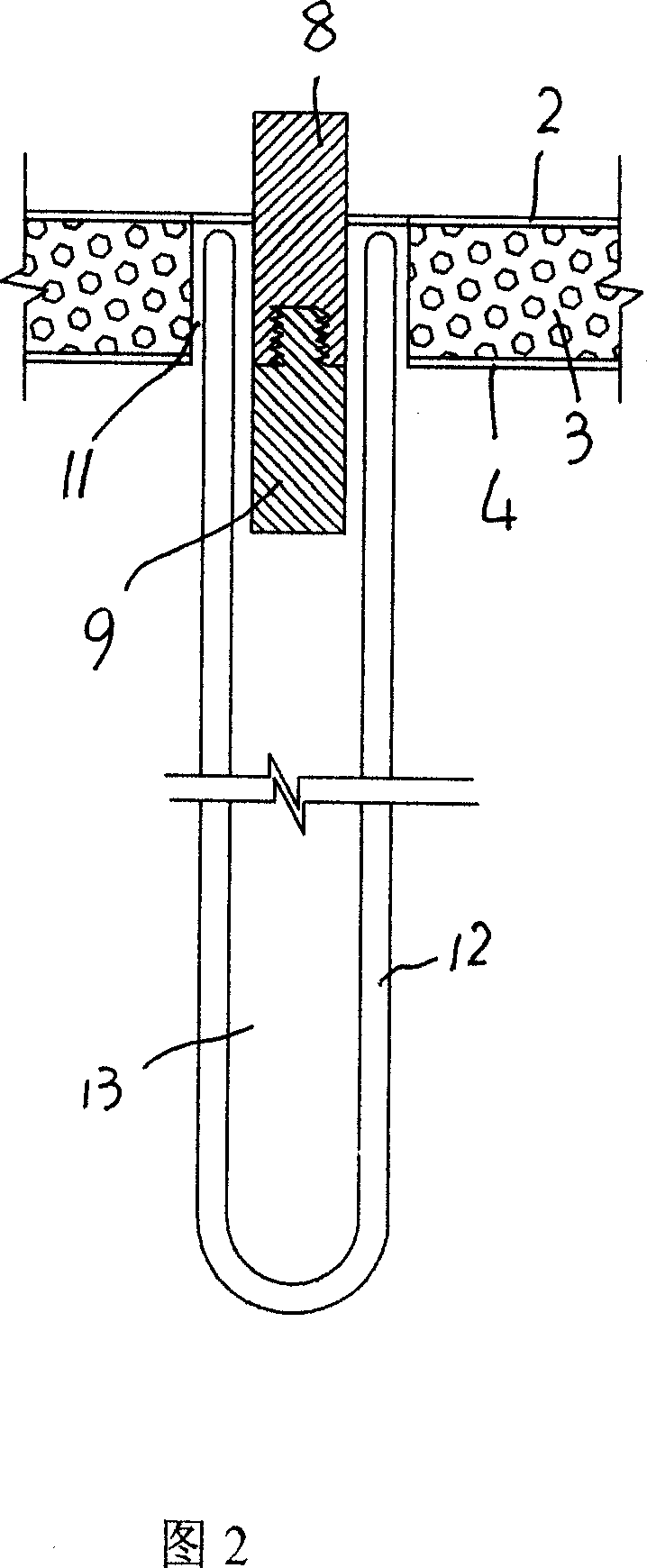

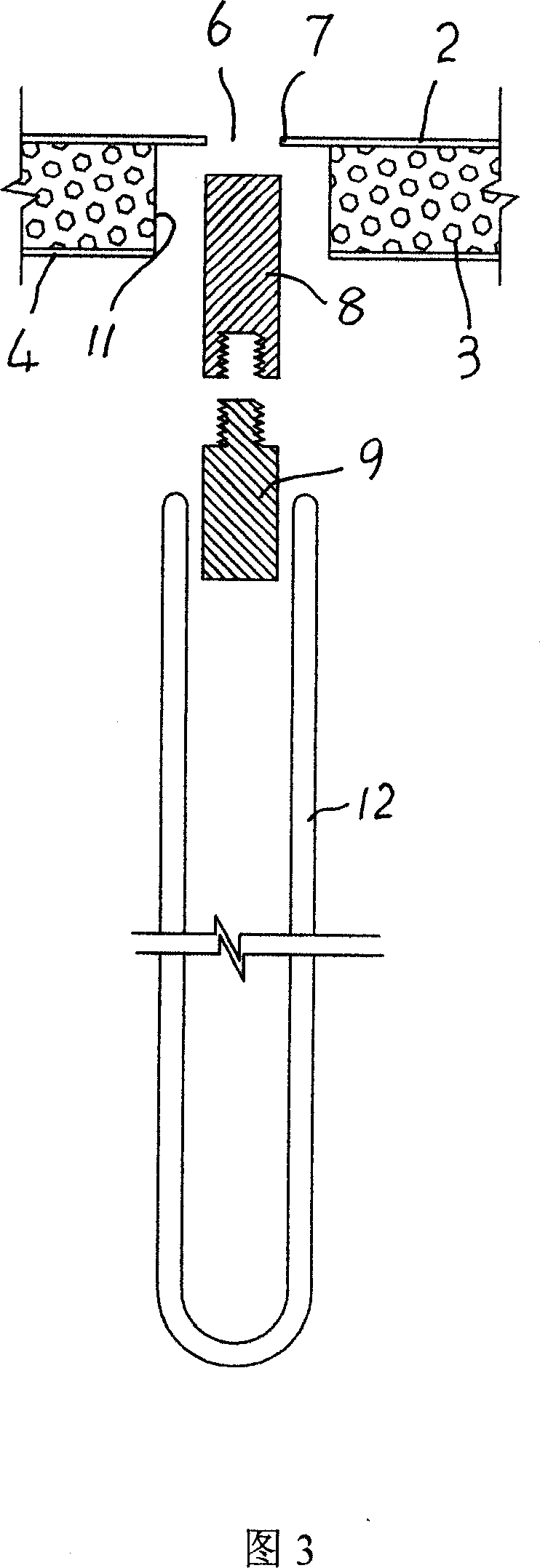

[0031] Referring to Fig. 1, a pressurized water tank 1 and a vacuum heat collecting tube 12 are adopted, and a metal heat conduction rod 5 is arranged, and the metal heat conduction rod 5 is embedded in the water tank liner 2 with its upper embedded section 8, and inserted with its lower extended section 9. In the vacuum heat collecting tube 12, the metal heat conducting rod 5 is used to block the metal heat conducting rod insertion port 6 on the water tank liner 2 at the position of the vacuum heat collecting tube 12, and the nozzle of the vacuum heat collecting tube 12 is placed in the pressurized water tank 1 In the reserved opening 11 of the water tank insulation layer 3 and the shell 4.

[0032] In specific implementation, the metal heat-conducting rod 5 seals the metal heat-conducting rod insertion port 6 on the water tank liner 2 by welding it to the water tank liner 2 .

[0033] In order to facilitate assembly and transportation, the embedded section 8 and the extensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com