Tray type excarvating contrary construction method

A construction method, basin-type excavation technology, which is applied in excavation, foundation structure engineering, building construction, etc., can solve the problems of reducing construction area, slow project progress, and large opening distance, so as to reduce excavation costs and ensure structural integrity. Quality and the effect of ensuring the safety of the foundation pit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

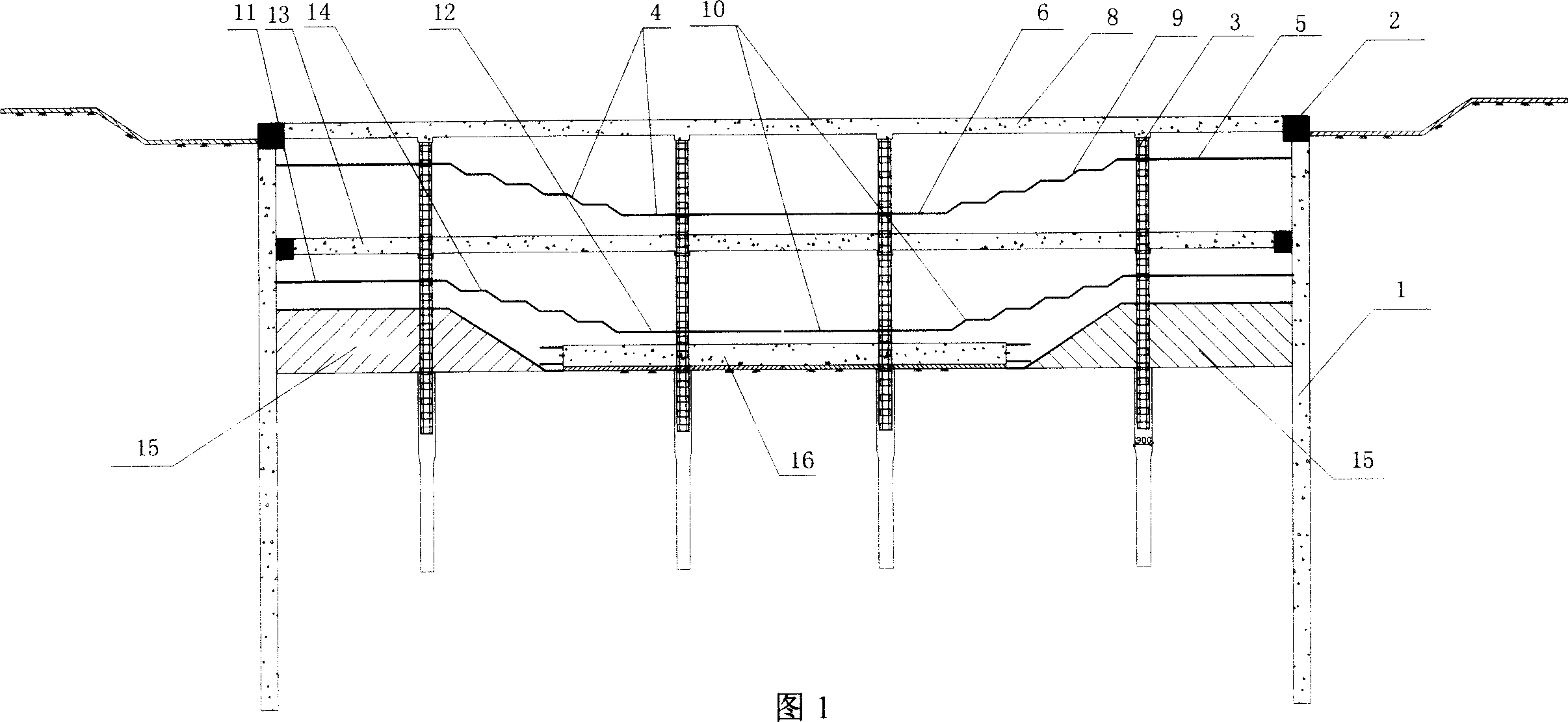

[0019] A project has a large foundation pit area of 40,000m 2 , with a depth of 12.6m, involving micro-confined water layers, and complex surrounding environmental conditions. In order to control the deformation of the foundation pit and increase the workload of open excavation, the reverse method of basin excavation was adopted. The specific construction steps of this method are as follows:

[0020] 1. Set up the enclosure structure 1 and purlin 2 around the site to be constructed, and set up the steel column 3;

[0021] 2. The first earthwork excavation: the first earthwork excavation starts from the edge of enclosure structure 1, and in order to reduce the impact of foundation pit excavation on the surrounding environment, unloading excavation is adopted to dig out a basin structure 4 , the elevation of basin top 5 is -5.00m, the elevation of basin bottom 6 is -7.50m, and then a cushion layer is laid on the basin structure 4 soil layer. The distance between the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com