Method for manufacturing polarizing plate, polarizing plate, optical film and image display device using them

An image display device, polarizing film technology, applied in optics, optical elements, optical elements, etc., can solve problems such as hindering the enlargement of polarizers, deviation of optical characteristics, etc. the benefits of a large effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Use a polyvinyl alcohol (PVA) film (manufactured by Kuraray Co., Ltd., degree of polymerization: 2400) with a thickness of 80 μm and a length of 2700 mm in the width direction. Stretched to 3 times in a 0.3 wt% iodine aqueous solution, then stretched in an aqueous solution of 4 wt% boric acid and 3 wt% potassium iodide to a cumulative draw ratio of 6 times, and immersed in a 3.5 wt% potassium iodide solution at 30°C for 10 seconds Thereafter, the film was dried at 30° C. for 4 minutes while maintaining the tension of the film to obtain a polarizing film having a length of 1340 mm in the width direction. Both ends in the width direction of the obtained polarizing film were cut off by 40 mm from the ends, respectively, to obtain a polarizing film having a length of 1260 mm in the width direction. Use the adhesive agent that fully saponified polyvinyl alcohol 5% aqueous solution is main component, on both sides of the polarizing film after cutting, stick the triacetyl cell...

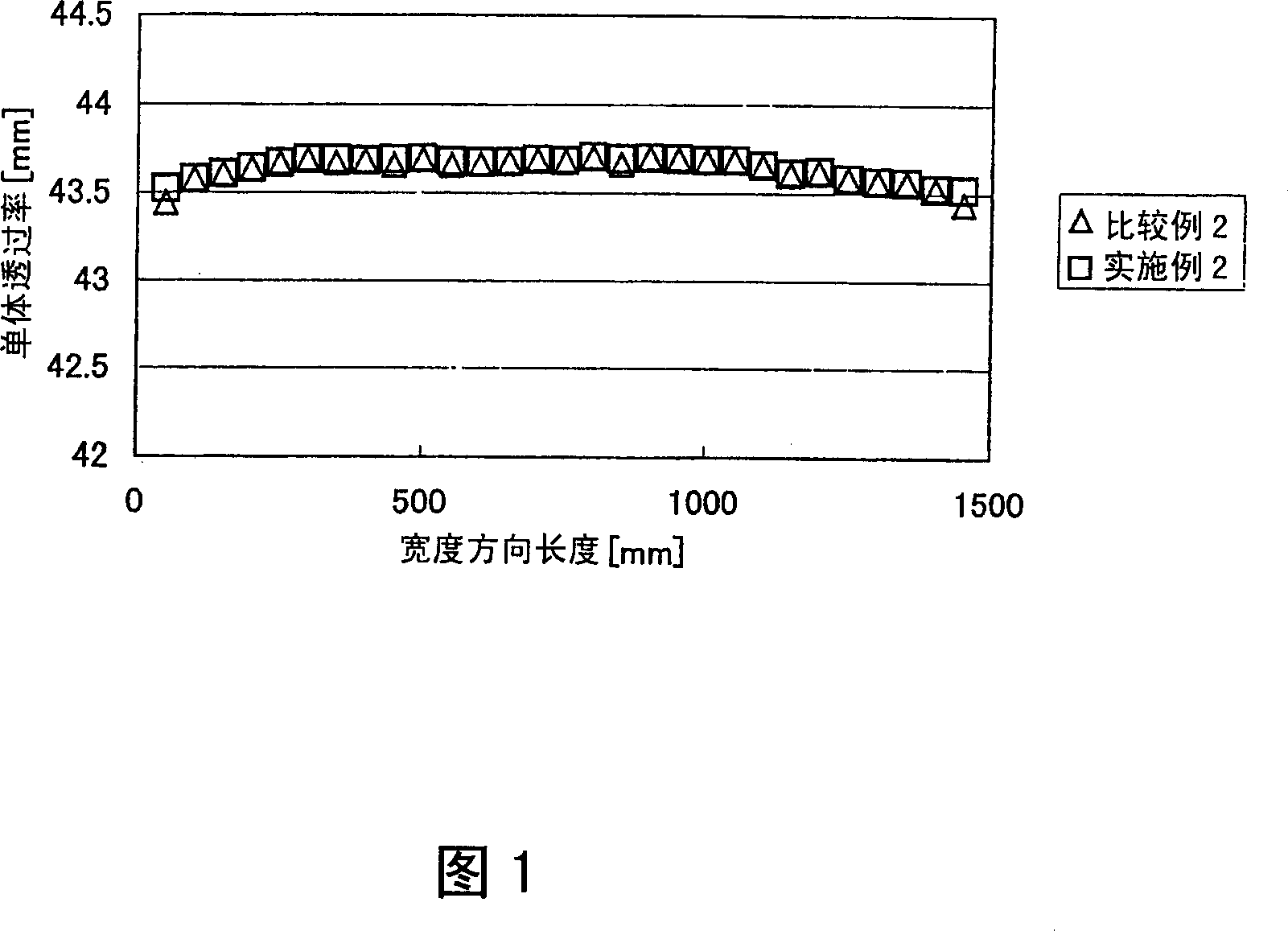

Embodiment 2

[0066] Using a polyvinyl alcohol (PVA) film with a thickness of 75 μm and a length of 3100 mm in the width direction (manufactured by Kuraray, degree of polymerization: 2400), a polarizing film was produced in the same manner as in Example 1 to obtain a polarizing film with a length of 1540 mm in the width direction. Both ends in the width direction of the obtained polarizing film were cut 40 mm from the ends, respectively, to obtain a polarizing film having a length of 1460 mm in the width direction. Use the adhesive agent that is main component with completely saponified polyvinyl alcohol 5% aqueous solution, on both sides of the polarized light film after cutting, stick the triacetyl cellulose (TAC) film (manufactured by Fuji Photo Film Co., Ltd.) of width direction length 1475mm: TDY80UL), by drying at 70° C. for 4 minutes to obtain a polarizing plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com