Device for fusing injection needle

An injection needle and fusing technology, which is applied in hypodermic injection devices, needles, medical science and other directions, can solve the problems of reduced use efficiency of electrode rollers, refractory damage and adhesion, and increased processing costs, so as to reduce processing costs and save money. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

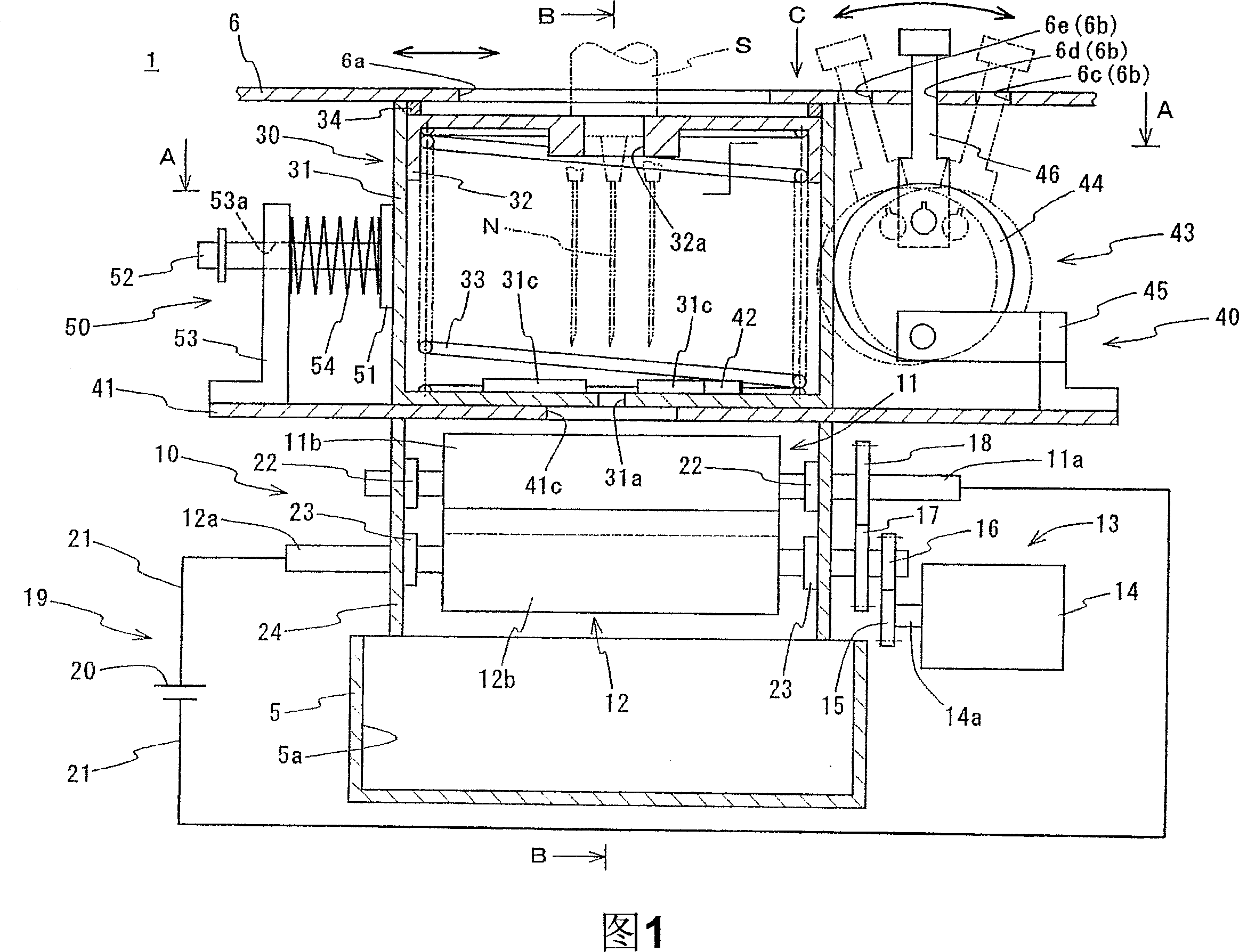

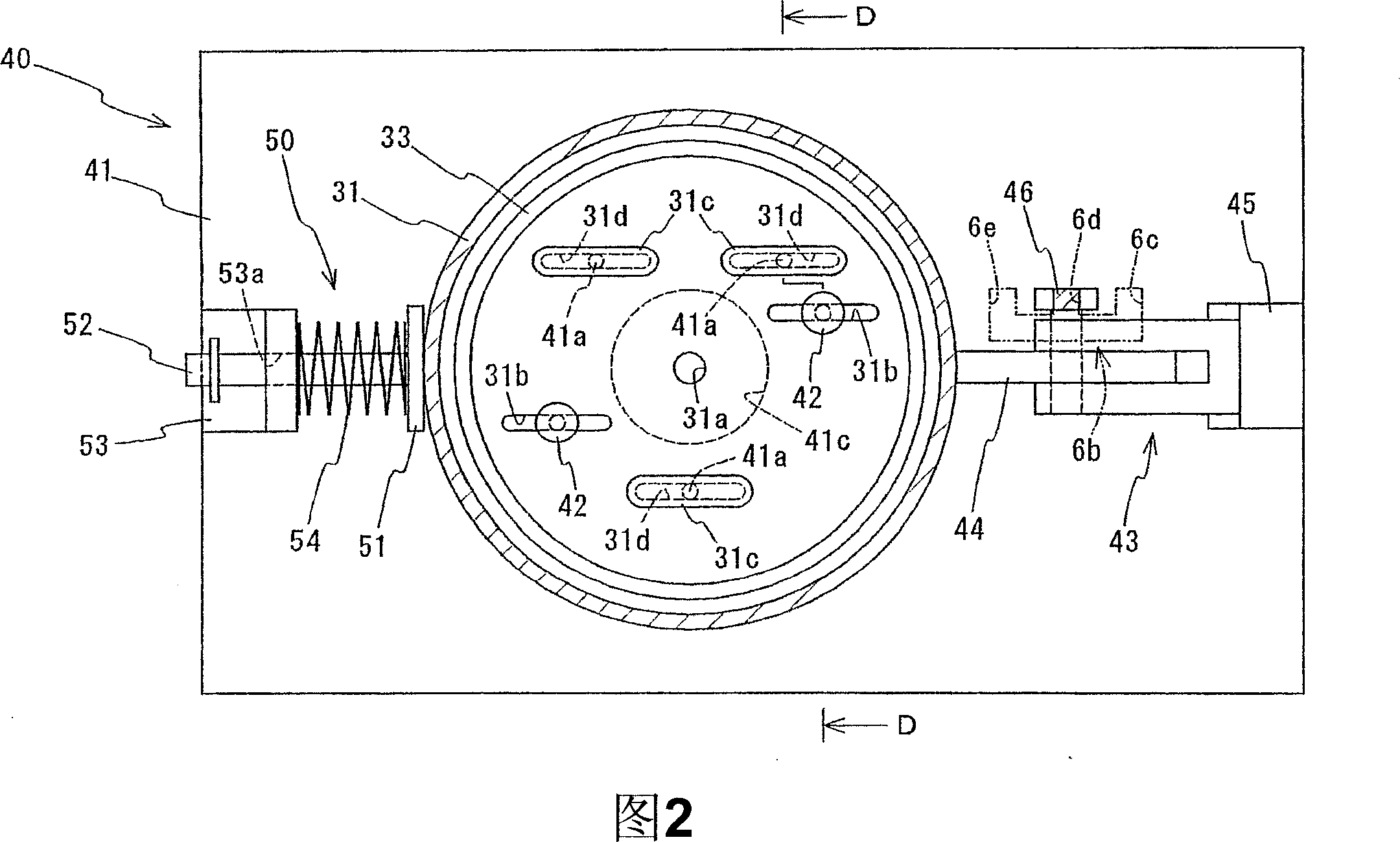

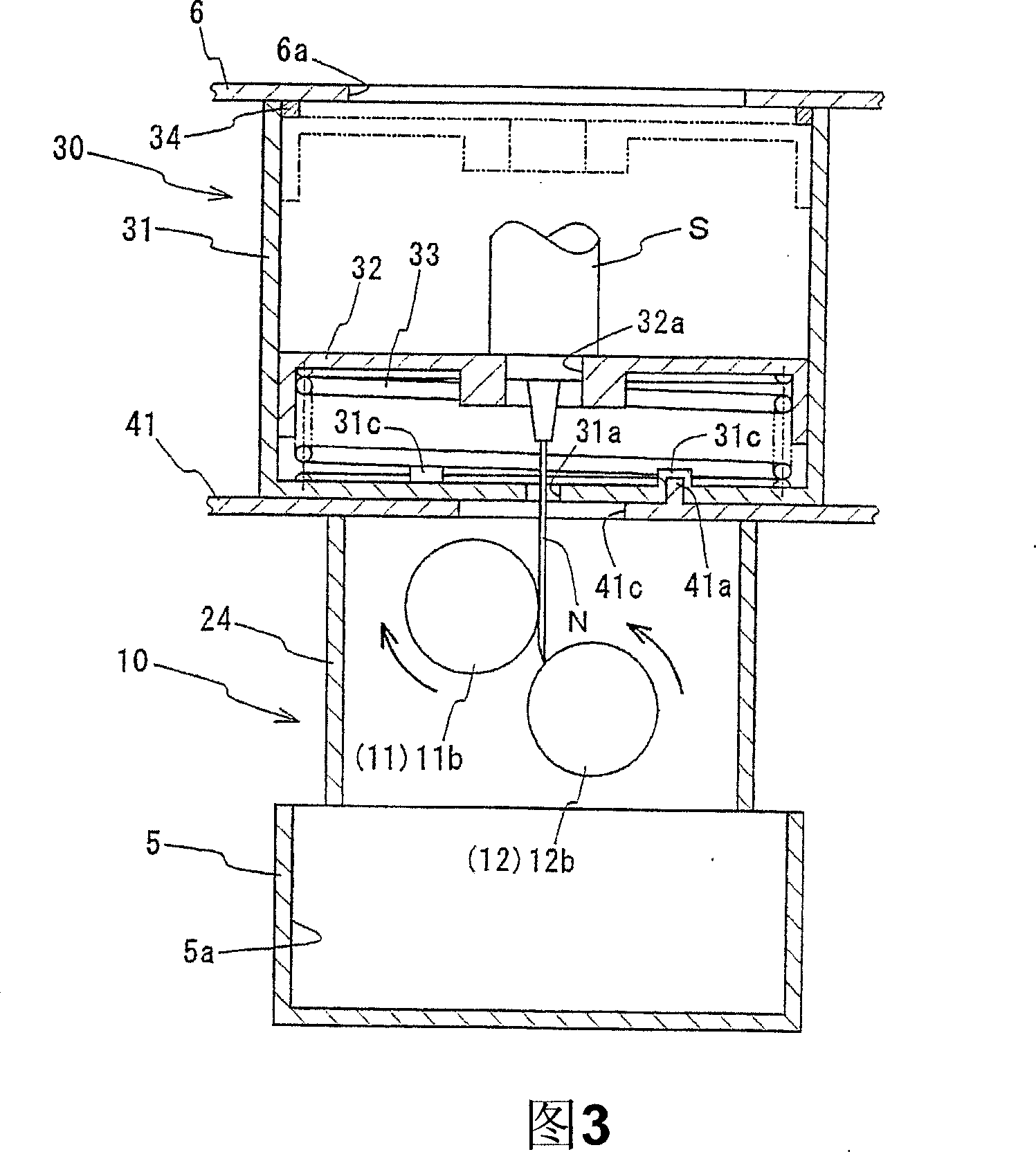

[0039] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. Among them, Fig. 1 is a cross-sectional view showing a schematic structure of an injection needle fuse device according to an embodiment of the present invention, Fig. 2 is a cross-sectional view in the direction of A-A indicated by an arrow in Fig. 1 , and Fig. 3 is a cross-sectional view indicated by an arrow in Fig. 1 . A cross-sectional view in the B-B direction is shown. In addition, FIG. 4 is a plan view in the direction C indicated by the arrow in FIG. 1 , and FIG. 5 is a cross-sectional view in the direction D-D indicated by the arrow in FIG. 2 .

[0040]As shown in Figures 1 to 5, the injection needle fusing device 1 of the present embodiment includes: a fusing mechanism 10 for fusing the injection needle N of the syringe S; a guide mechanism 30 for guiding the injection needle N to the fusing mechanism 10; adjusting the fusing mechanism 10 and The posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com