Multi-optical-fiber port platform and mfg. method

A multi-fiber, multi-fiber technology, applied in the direction of bundle optical fiber, light guide, optics, etc., can solve the problems of limited application scope, high cost, unsuitability, etc., and achieve the effect of wide application scope, simple manufacturing process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

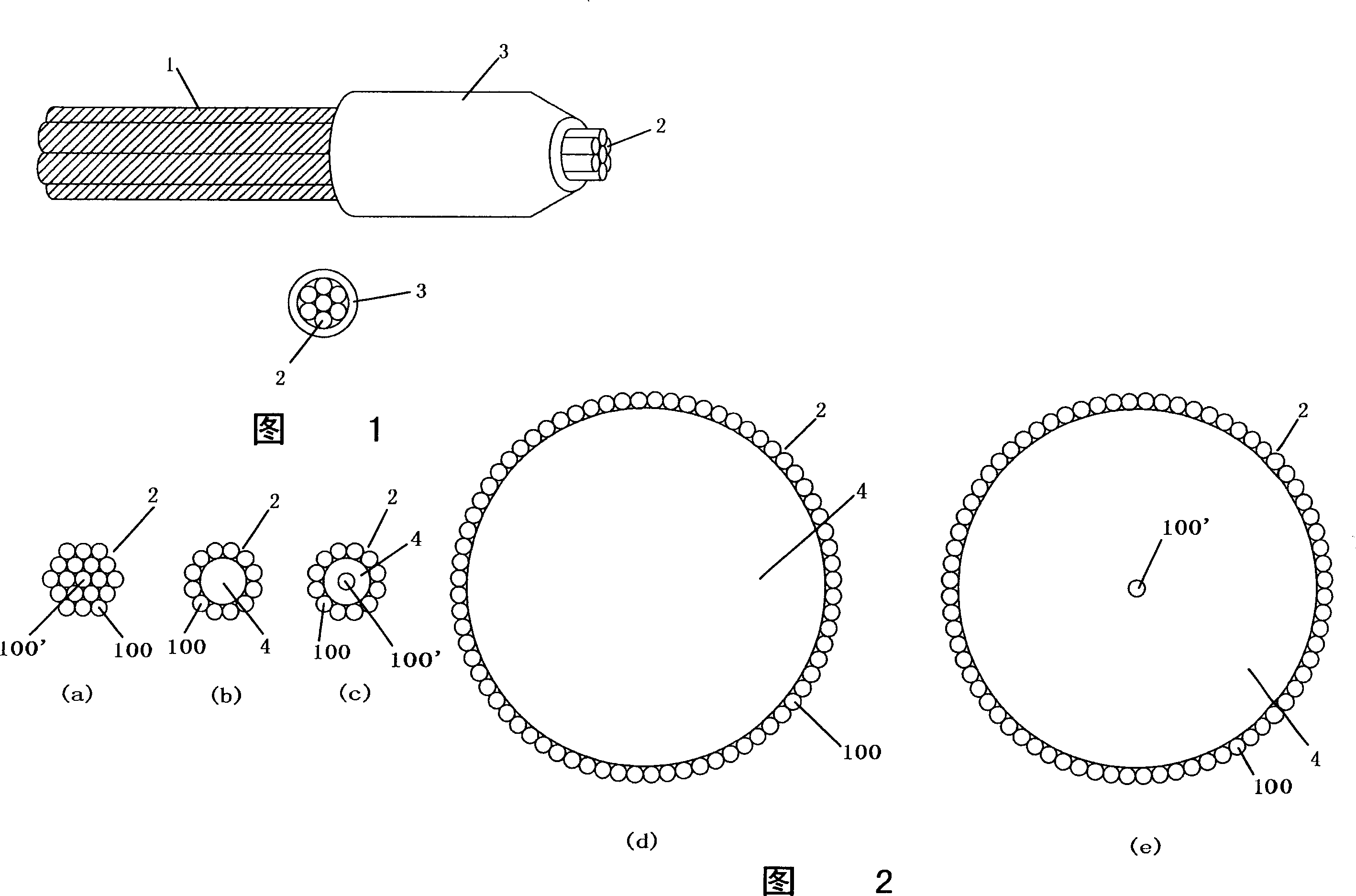

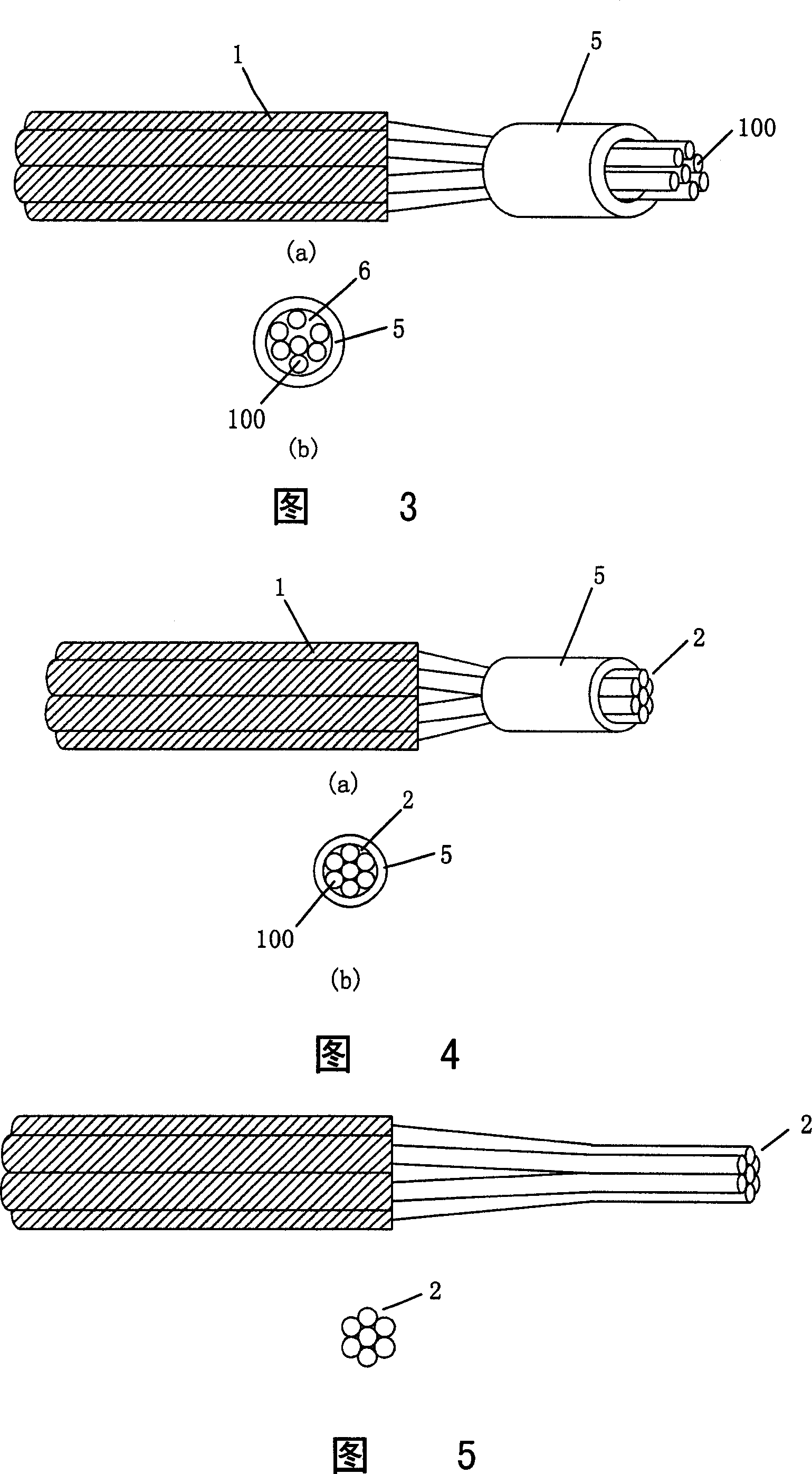

[0045] Fig. 1 has illustrated the multi-fiber port platform provided by the present invention, comprises the multiple optical fiber 1 that contains coating, comprises the optical fiber bundle 2 of the multiple optical fiber that removes coating at one end of multiple optical fiber 1 and ferrule 3, and optical fiber bundle 2 The gaps between the multiple optical fibers in the optical fiber bundle are sub-micron, the gap between the main body of the optical fiber bundle 2 is occupied by optical thermosetting glue or ultraviolet glue, the entire optical fiber bundle 2 is accommodated in the ferrule 3, and can be heated It is fixed in the ferrule 3 by means of solid glue or ultraviolet glue.

[0046]The fiber optic bundle 2 can have various cross-sectional shapes. In Fig. 2 (a), the optical fiber bundle 2 is formed by 18 optical fibers 100 surrounding the central optical fiber 100'; Material 4 can be glass rod, glass filament, silicon rod, silicon filament, ceramic rod or ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com