Damage-free detection system for strong conveying belt

A non-destructive testing, conveyor belt technology, applied in the use of radiation for material analysis, etc., can solve the problems of adverse reactions, long detection time, low efficiency, etc., to achieve image contrast and definition enhancement, spatial resolution improvement, system resolution high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

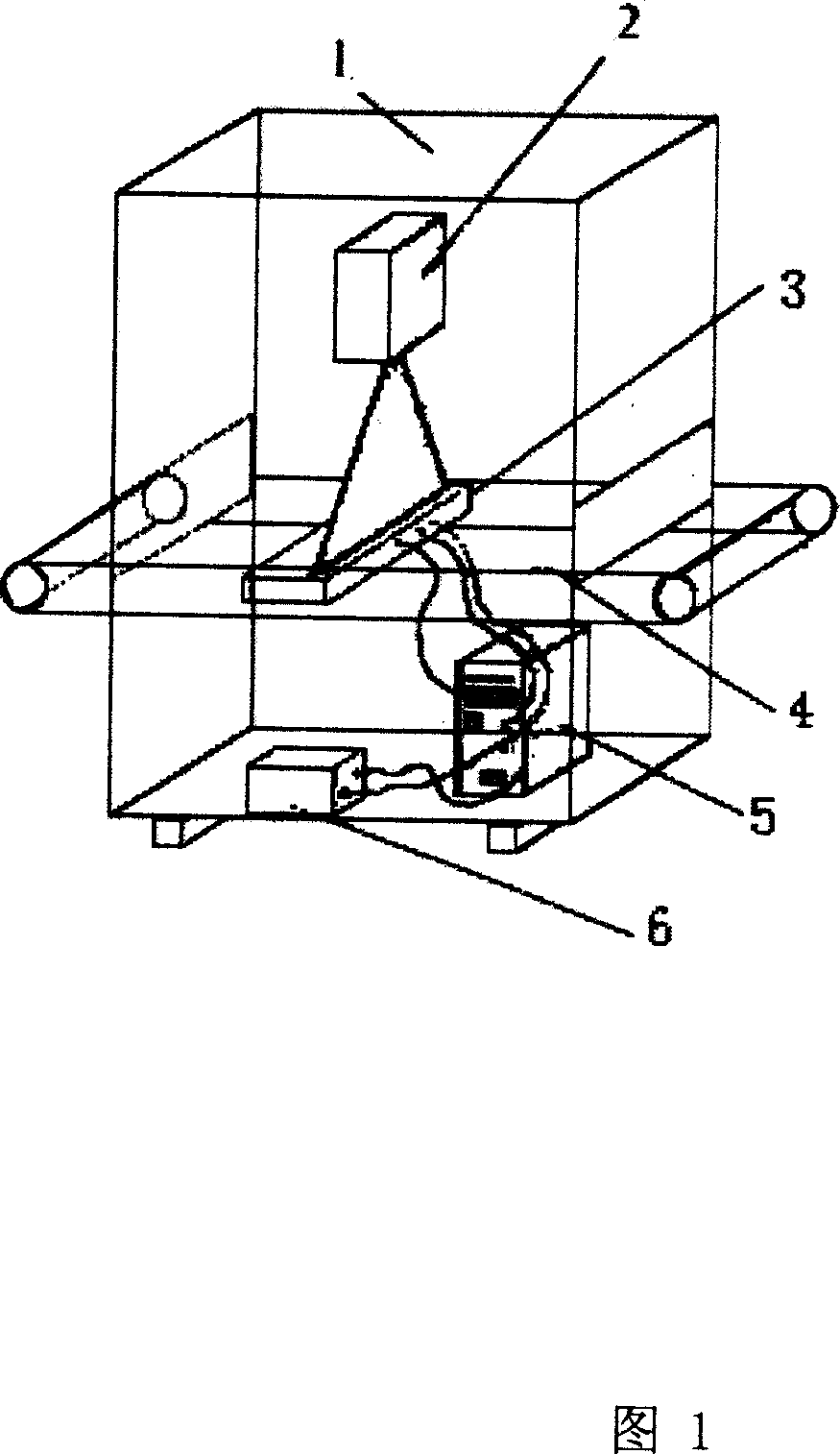

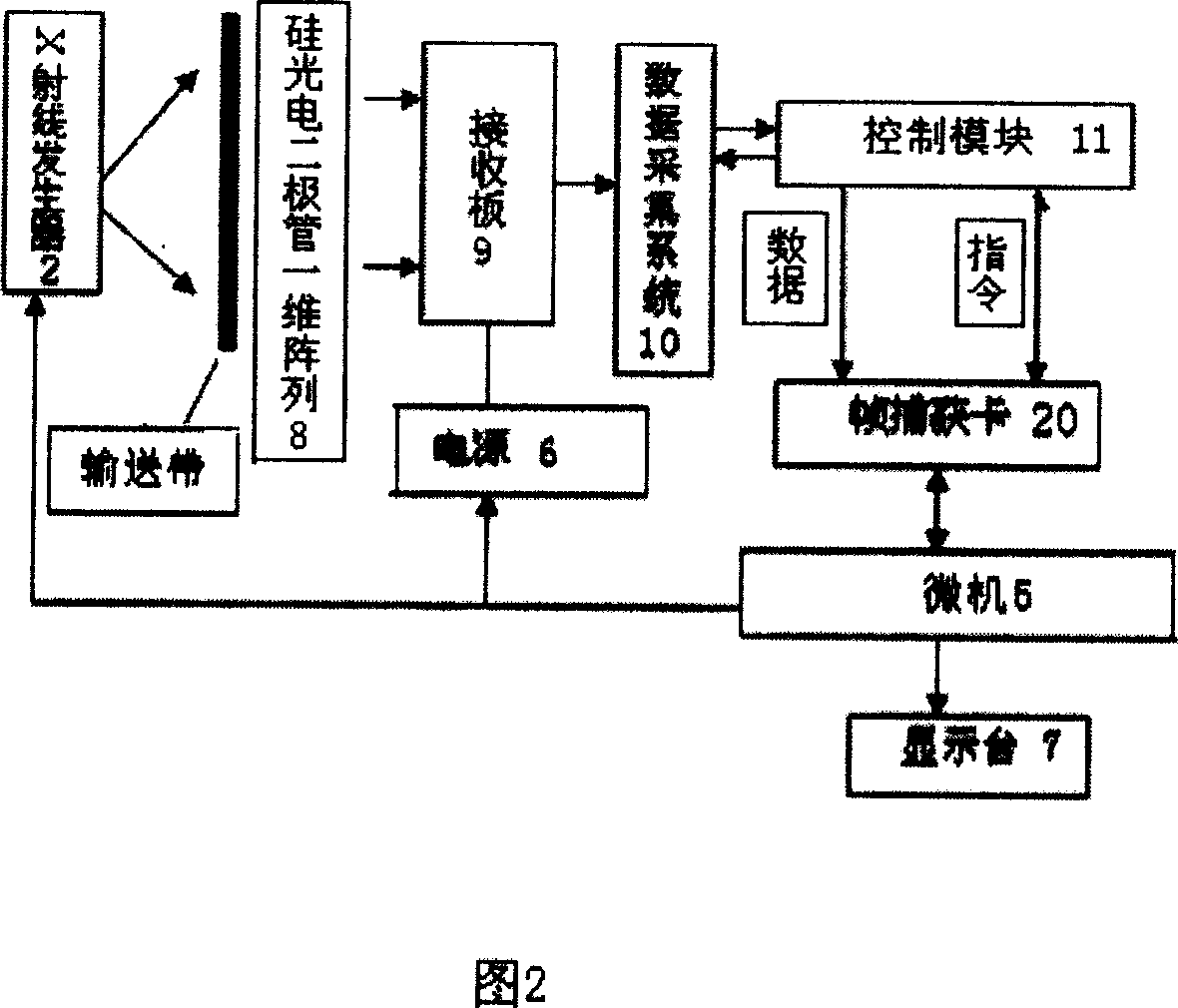

[0039] The non-destructive detection system of the strong conveyor belt of the present invention will be further described below in conjunction with the accompanying drawings.

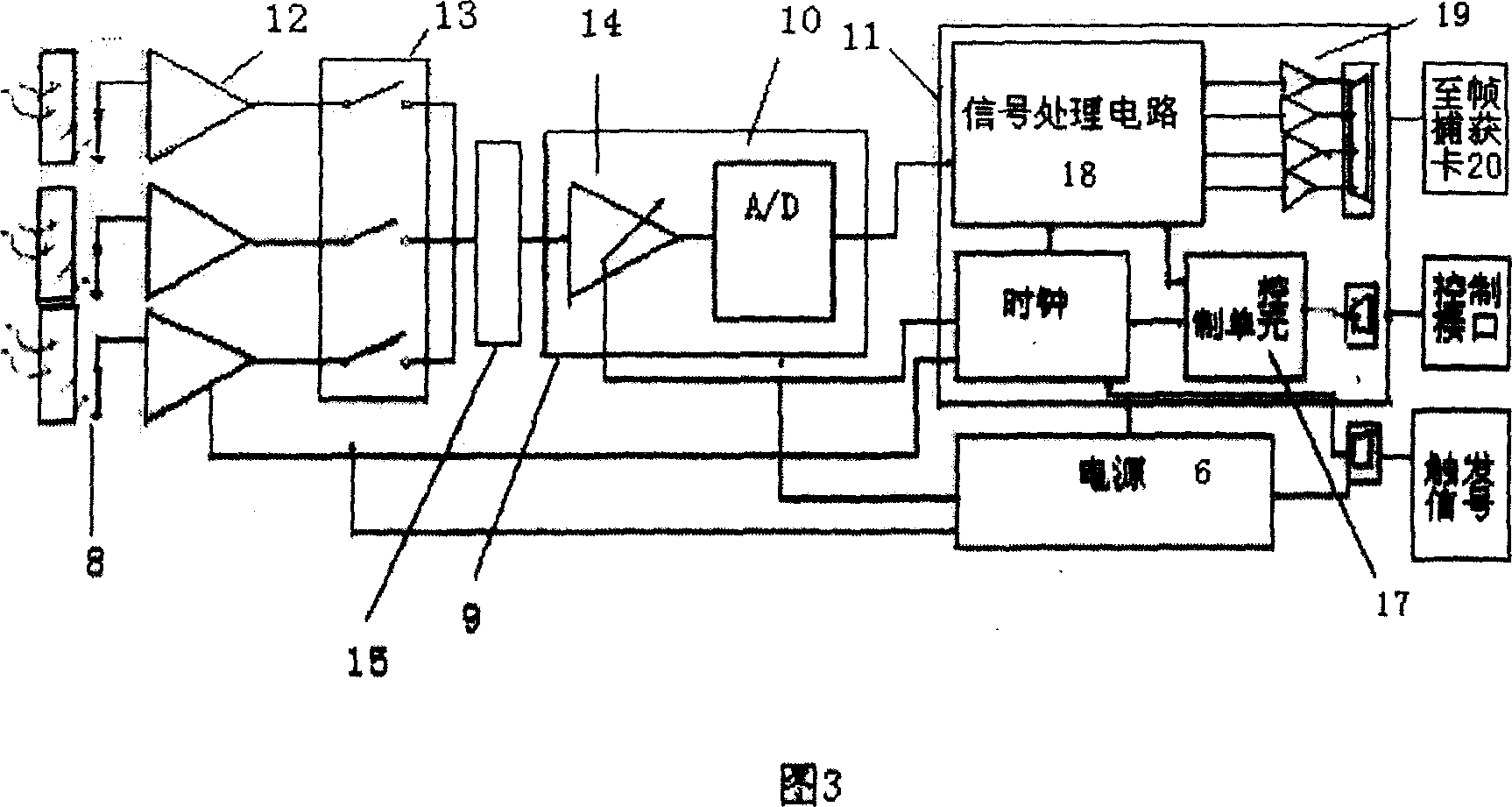

[0040] The structure of the strong conveyor belt non-destructive testing system of the present invention is that there is a T-140 type X-ray generator 2 that can work continuously in the monitoring system box and radiation shielding 1, and is placed on one side of the strong conveyor belt of the object under test, and the X-rays generate The X-rays sent by the device 2 pass through the strong conveyor belt and are received by the X-ray receiving / control board 3 placed on the opposite side of the strong conveyor belt. The X-ray receiving / controlling board 3 includes a one-dimensional array 8 composed of photoelectric cells, and the electrical signals containing image pixels of the object under test are amplified and filtered before being sequentially collected. After the analog signal is amplified by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com