Copper and aluminium composite pipe

A technology of aluminum composite and copper pipes, applied in the fields of aluminum composite pipes and copper, can solve the problems of easy aging, short service life and high cost of plastic pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

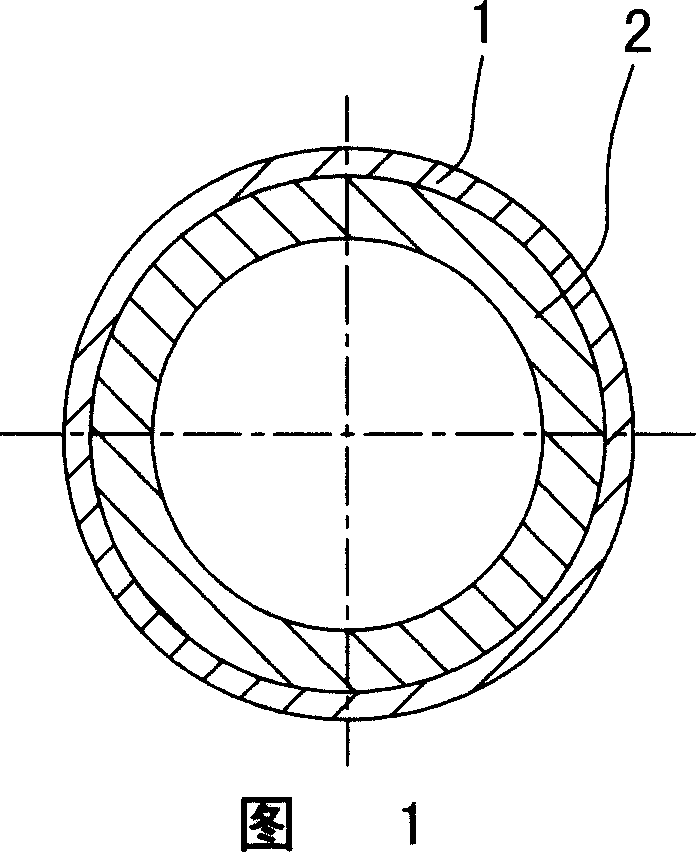

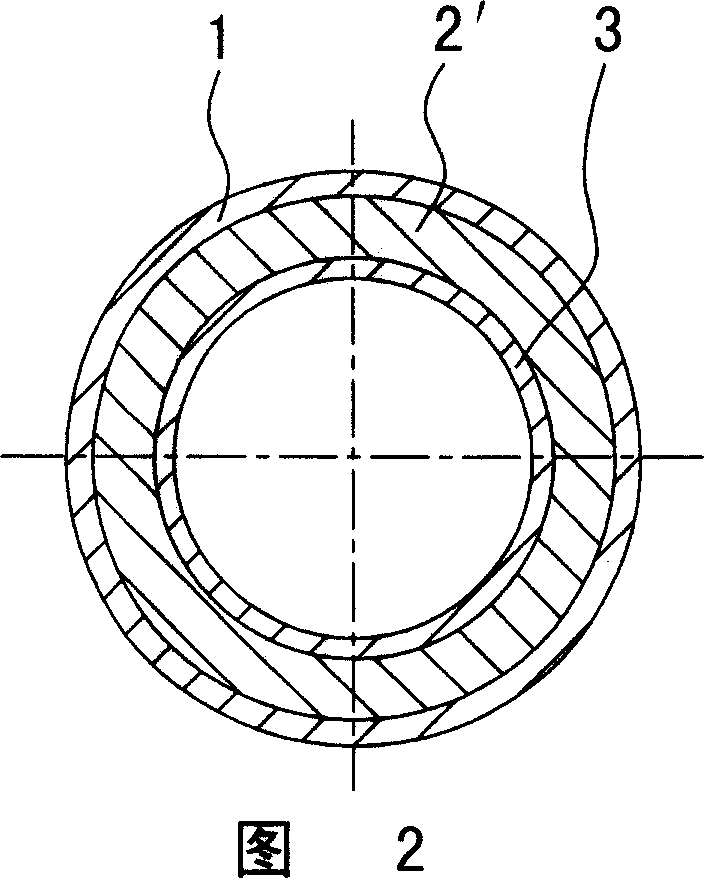

[0008] The invention discloses a copper-aluminum composite pipe, which is mainly used in refrigeration appliances such as air conditioners, refrigerators and other products, and can also be used in cold and hot water supply pipes in buildings. Tube or seamless aluminum tube, its main technical feature is that the tube wall of the copper and aluminum composite tube made of seamless copper tube and seamless aluminum tube is two or three layers, and the structure of two layers (as shown in Figure 1, Shown in Fig. 3), shown in Fig. 1, its outer layer is seamless copper tube layer 1, and inner layer is seamless aluminum tube layer 2, or as shown in Figure 3, outer layer is seamless aluminum tube layer 2 ", The inner layer is a seamless copper tube layer 1'; wherein the three-layer structure (as shown in Figure 2) is that the outer layer and the inner layer are seamless copper tube layers 1 and 3, and the middle layer is a seamless aluminum tube layer 2'. When the actual product is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com