Manufacture method of tin slot bottom brick

A tin bath bottom brick and manufacturing method, applied in the field of refractory materials, can solve the problem that air cannot be effectively eliminated, and achieve the effects of good Na2O corrosion resistance, fast demoulding, and high pressure frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Raw materials and their proportions:

[0023] 150Kg of burnt gems with a particle size of 5-3mm

[0024] 200Kg of burnt gems with a particle size of 3-1mm

[0025] Burnt gems with a particle size of 1-0mm 300Kg

[0026] 200Kg of burnt gem powder with a particle size of 0.088mm

[0027] Combined clay 150Kg

[0028] Calcium lignosulfonate 40Kg

[0029] Among the above-mentioned raw materials, the supplier of burnt gemstones is Shandong Wangcun bauxite; the combined clay is Guangxi soil; the calcium lignosulfonate is pulp waste liquid.

[0030] Prepare as follows:

[0031] 1) Add the aggregate to the kneader and mix well;

[0032] 2) mixing the coke clay and the burnt gemstone fine powder with a particle size of 0.088 mm, as a mixed powder for subsequent use;

[0033] 3) Pour the pulp waste liquid (calcium lignin sulfonate) into the kneader, and mix it with the aggregate for 5 minutes;

[0034] 4) Pour the mixed fine powder into the kneading pot and knead for 15 mi...

Embodiment 2-4

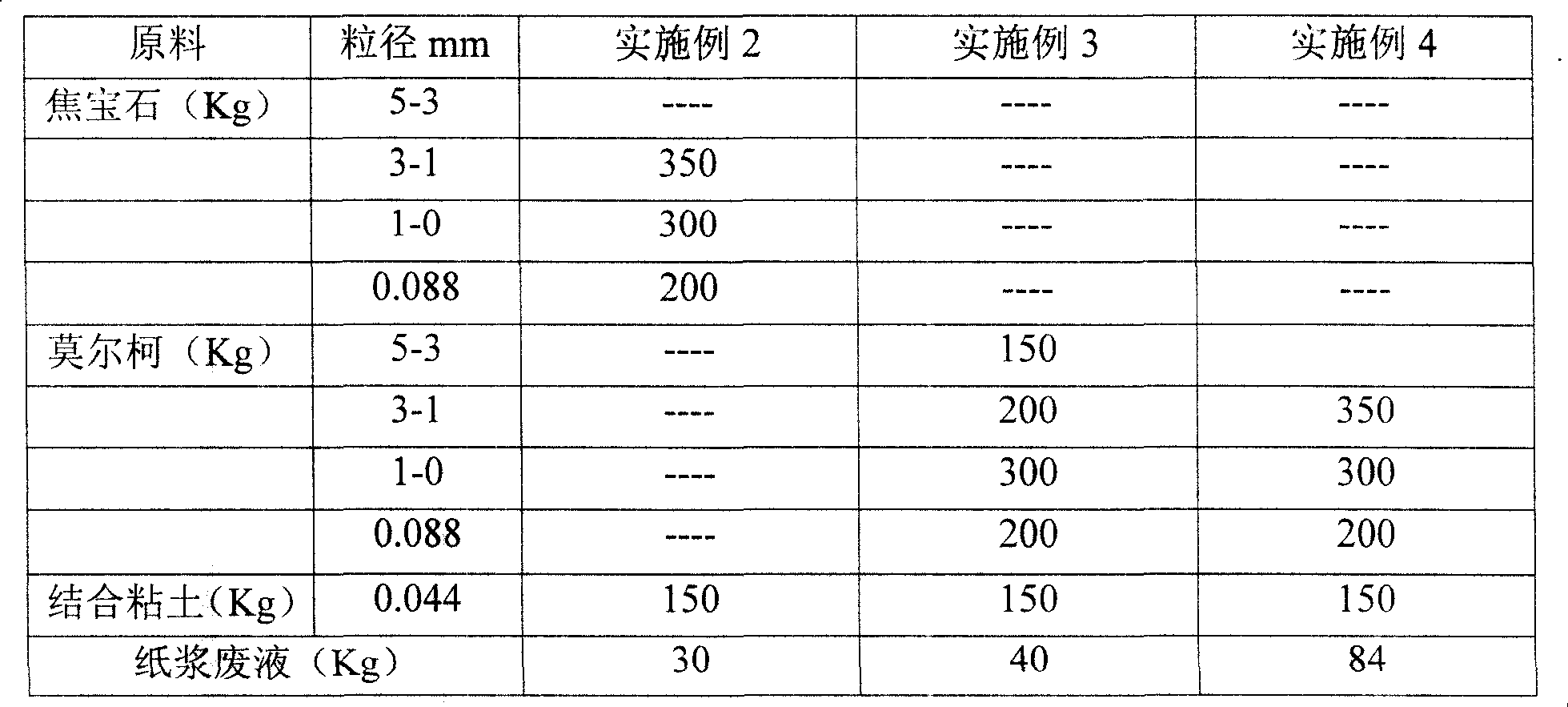

[0045] The preparation method is the same as in Example 1, except that in the method of manufacture: Example 2 is vacuumed to 0.05MPa, Example 3 is vacuumed to 0.07MPa, and Example 3 is vacuumed to 0.095MPa; raw materials, proportioning and the quality of the finished product The indicators are shown in Table 2 and Table 3.

[0046] Raw materials and their proportions:

[0047] Table 2: Embodiment 2-4 raw material and proportioning thereof

[0048]

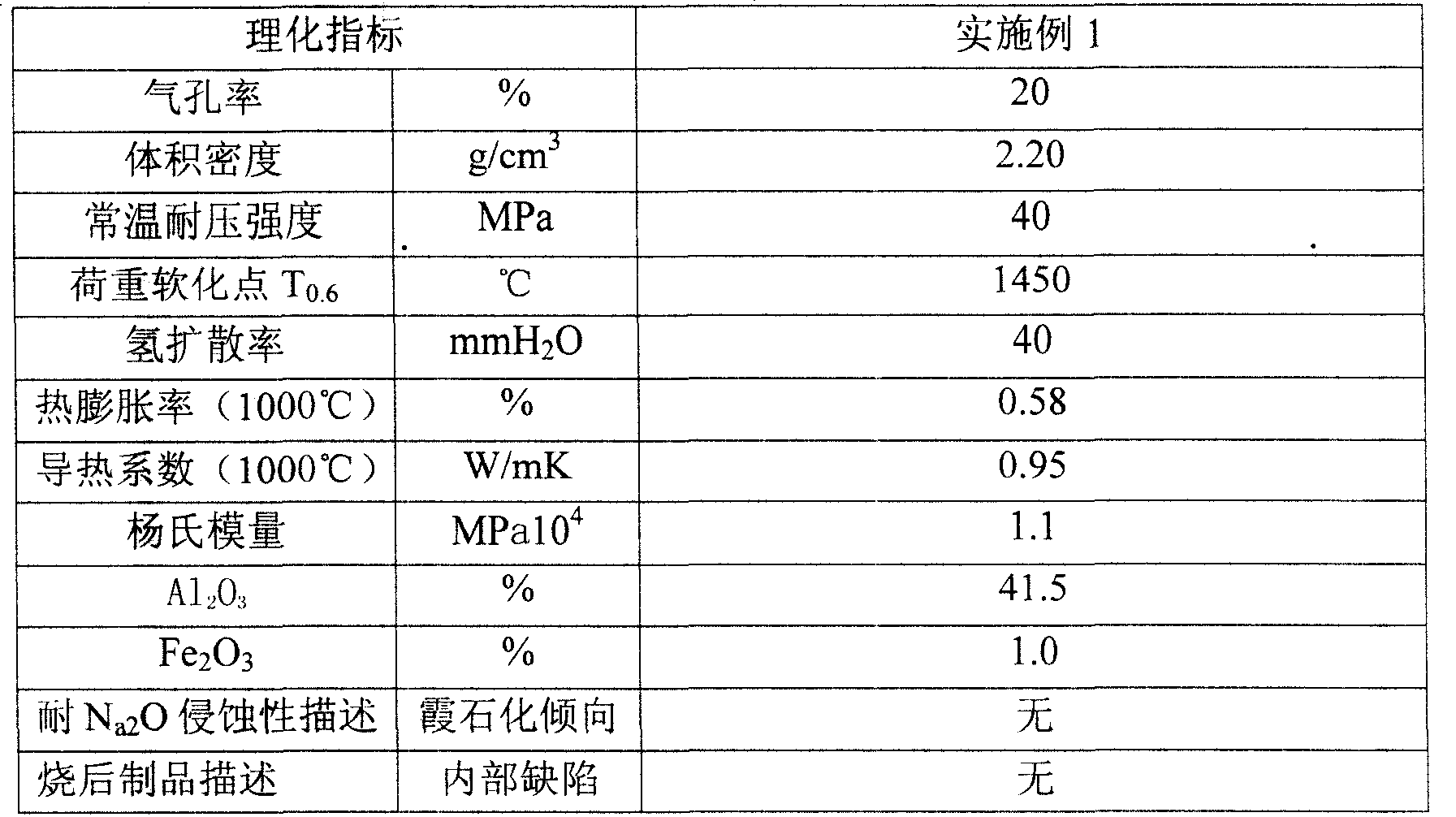

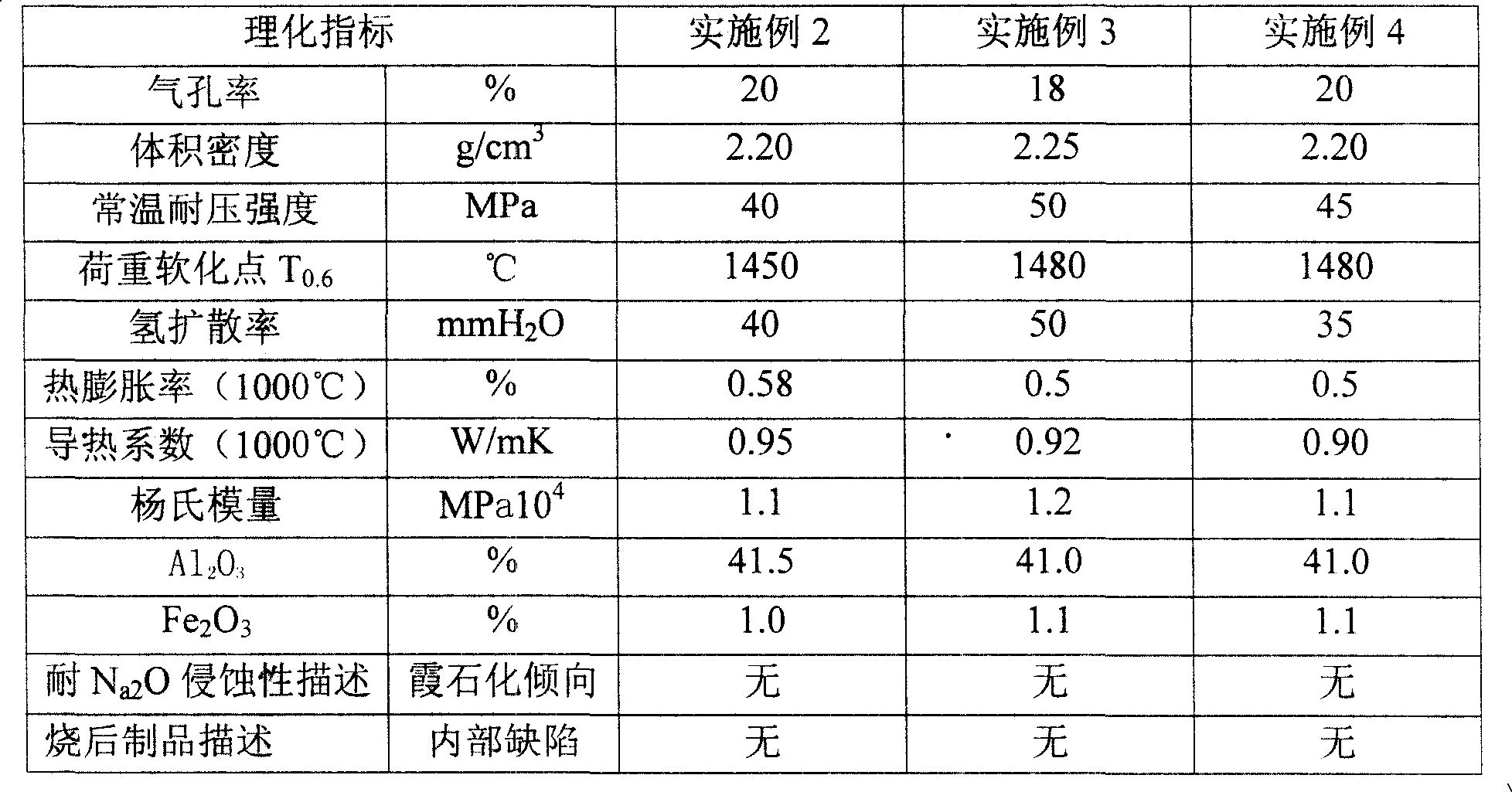

[0049] Quality Index

[0050] Table 3: The quality index that embodiment 2-4 makes tin bath bottom brick

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com