Nano powder preparing device and preparing method thereof

A nanopowder and system technology, applied in nanotechnology, chemical/physical/physicochemical processes of applied energy, coatings, etc., can solve the problems of low gas utilization rate, limited laser energy, and low yield of powder preparation, etc. Achieve high gas utilization rate, improve utilization rate, and high powder preparation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

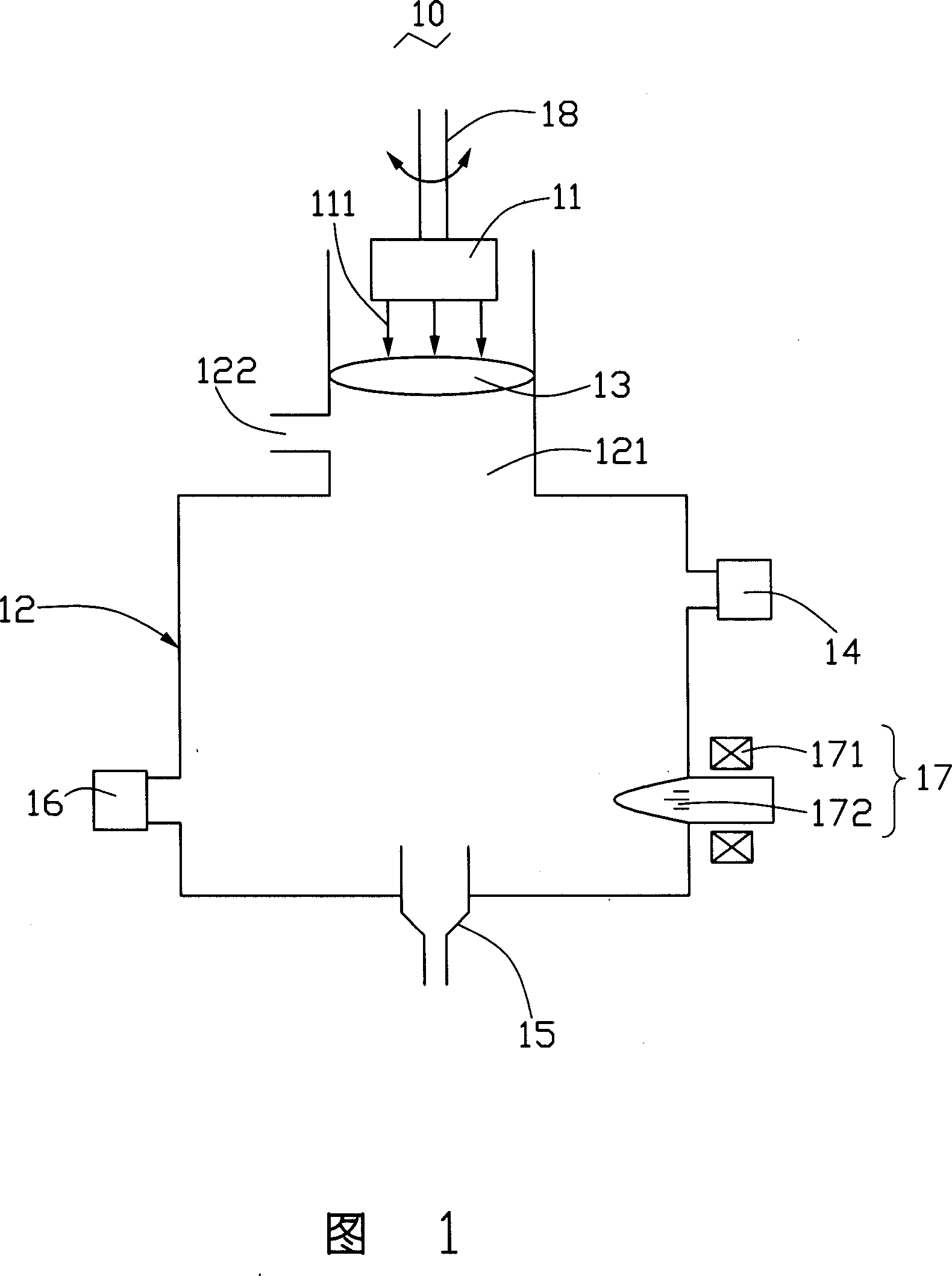

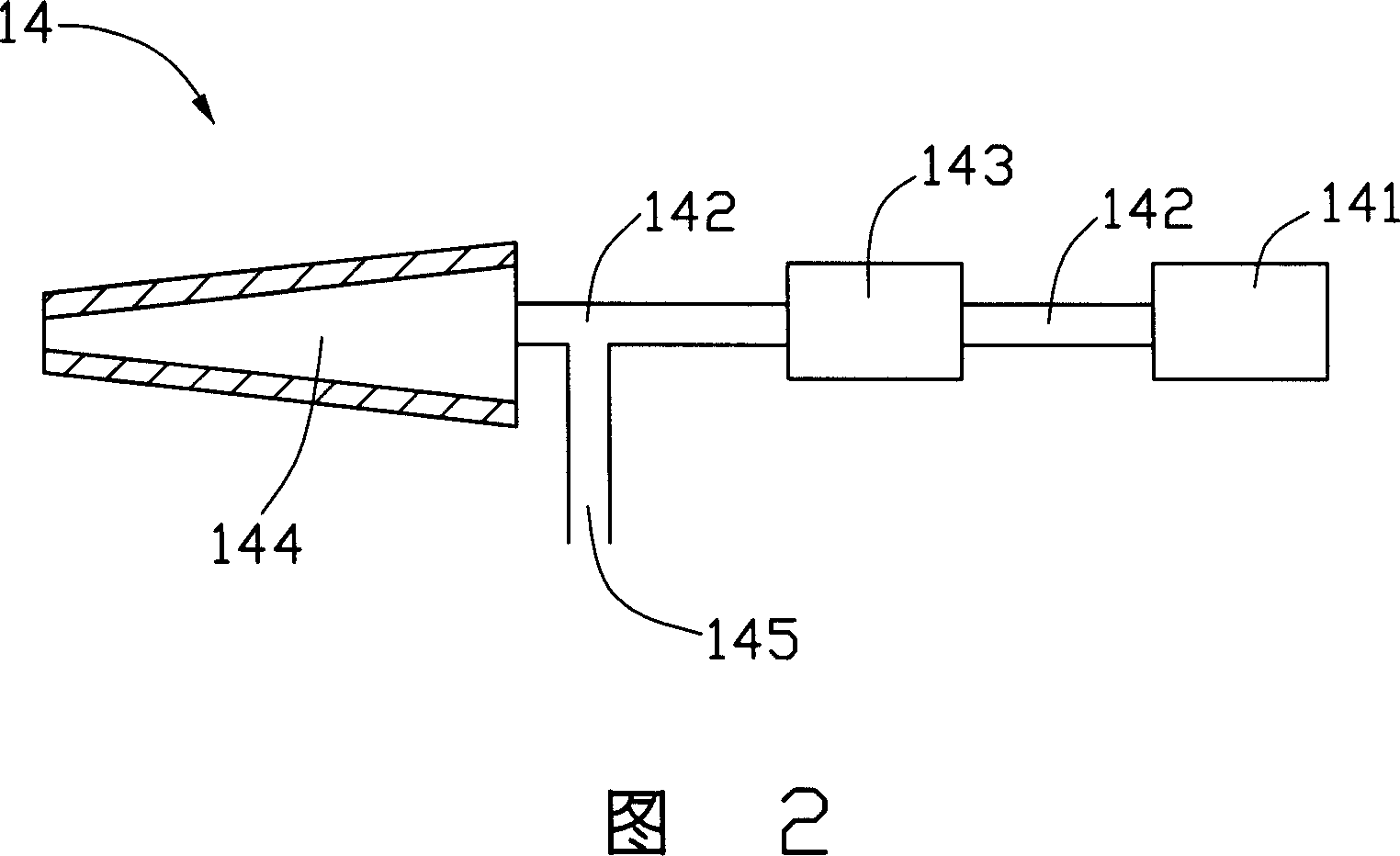

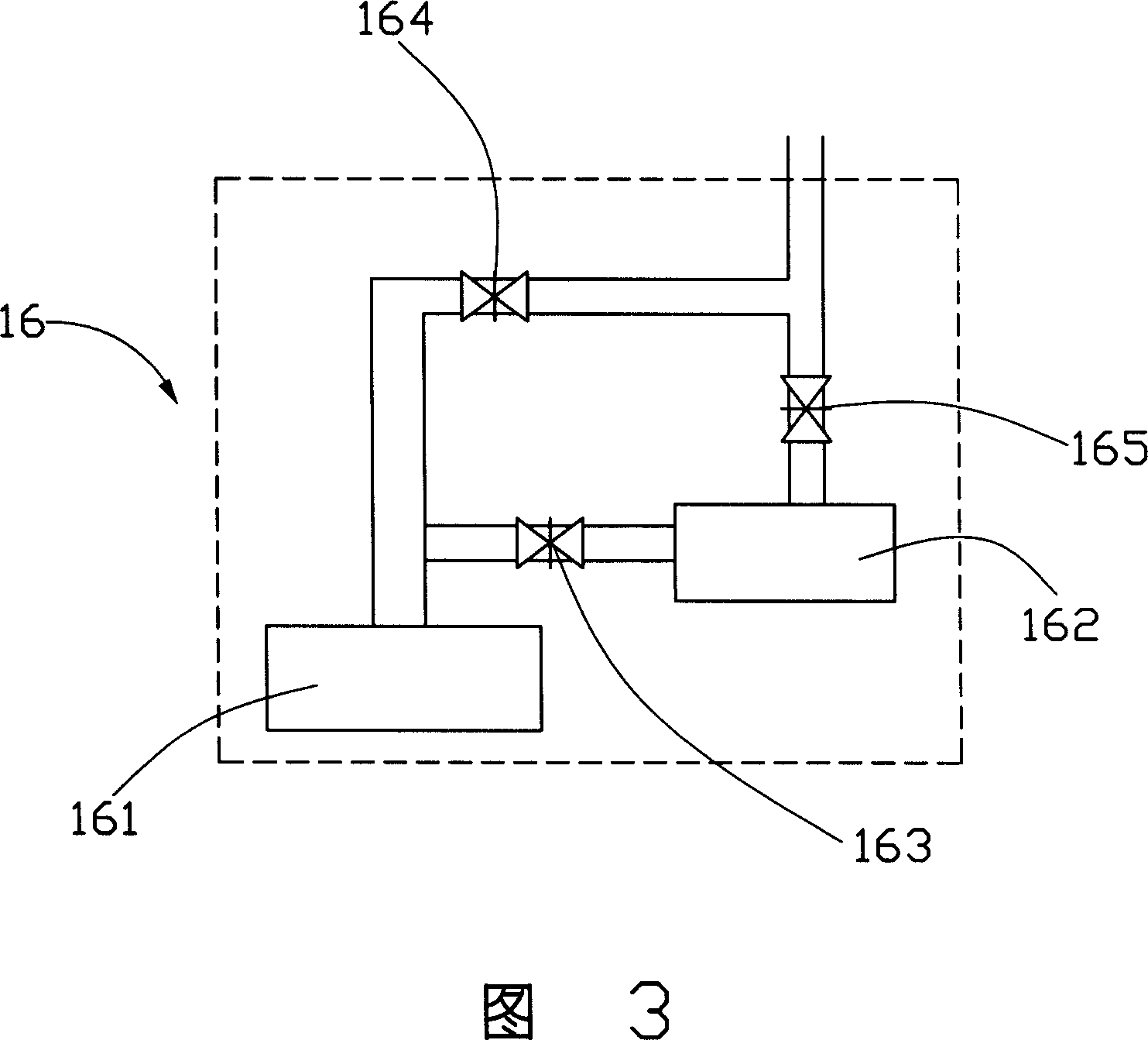

[0020] Please refer to Fig. 1, it is the nanopowder preparation device 10 that the embodiment of the present invention provides, this nanopowder preparation device 10 comprises reaction chamber 12, laser generator 11, optical system 13, reaction gas input device 14, powder collection Unit 15, vacuum device 16 and microwave generating unit 17.

[0021] Wherein, the laser generator 11 can be carbon dioxide (CO 2 ) laser, which can rotate around the axis 18 within a range of 360°, and the laser generator 11 can generate a laser beam 111 with a power between 100-1200 watts (w).

[0022] The reaction chamber 12 is an airtight container made of stainless steel. The reaction chamber 12 has an incident window 121 facing the laser generator 11 .

[0023] The optical system 13 is fixed between the incident window 121 and the laser generator 11, and the optical system 13 includes a focusing lens, which can be made of zinc arsenide (ZnAs). The laser beam 111 generated by the laser gener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com