A kind of preparation method of simulated cellulase

A cellulase, cellulose technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., to achieve high-value conversion, good degradation effect, and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

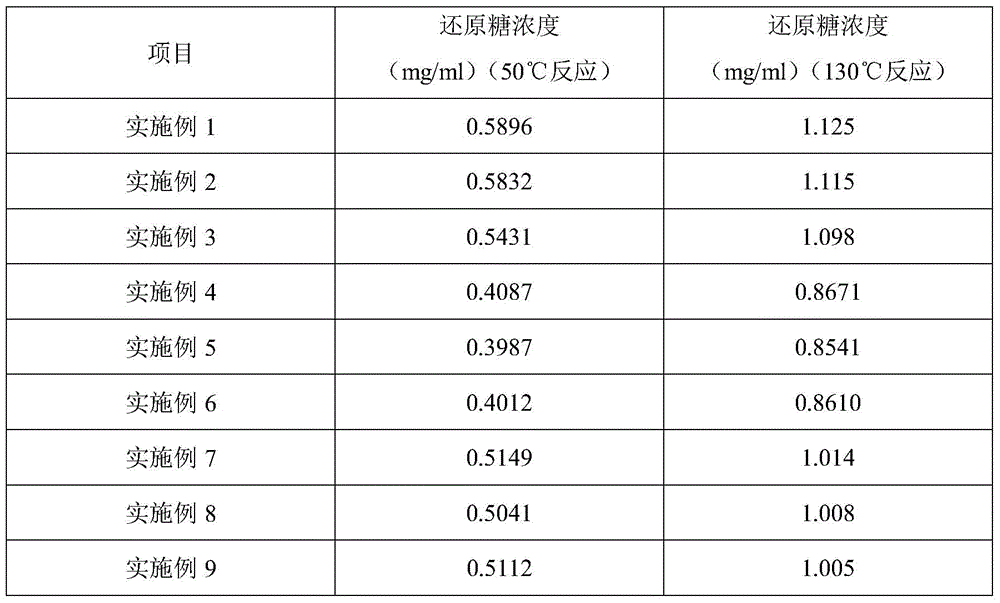

Embodiment 1

[0031] Example 1 Preparation of Morusyl Mimetic Enzymes.

[0032] (1) Take the mulberry branch and cut off the mulberry branch bark with a knife, cut off the mulberry branch bark, wash away the sediment with tap water, dry at 105° C. for 10 h, pulverize, and pass through a 200-mesh sieve to obtain the mulberry branch powder;

[0033] (2) Get 100g mulberry branch powder, add 1000g mass concentration and be the ionic liquid [EMIM][DEP] of 50% (w / v%), process 3h under the condition of 80 ℃, the treatment power of microwave treatment is 900w, treatment time 75s, add 1L of water to the system to precipitate the mulberry branch powder, wash with water 2 to 3 times to remove the ionic liquid (the aqueous solution of the ionic liquid can be distilled to remove water to a certain concentration and can be reused), and place it in a 70°C blast drying oven until dry to obtain the initial sample;

[0034] (3) Put the initial sample obtained in step (2) into a crucible, place it in a tube ...

Embodiment 2

[0037] Example 2 Preparation of Morusyl Mimetic Enzyme.

[0038] (1) Take the mulberry branch and cut off the mulberry branch bark with a knife, cut off the mulberry branch bark, wash away the sediment with tap water, dry at 100°C for 10 hours, pulverize, pass through a 200-mesh sieve, and obtain the mulberry branch powder;

[0039] (2) Get 100g mulberry branch powder, add 1000g mass concentration and be the ionic liquid [EMIM]Ac of 60% (w / v%), process 2h under 90 ℃ of conditions, the processing power of microwave processing is 800w, and processing time 70s, Add 1L of water to the system to precipitate the mulberry branch powder, wash with water 2 to 3 times to remove the ionic liquid (the aqueous solution of the ionic liquid can be distilled to remove water to a certain concentration and can be reused), and place it in a blast drying oven at 75°C until dry , get the initial sample;

[0040] (3) Put the initial sample obtained in step (2) into a crucible, place it in a tube f...

Embodiment 3

[0043] Example 3 Preparation of Morusyl Mimetic Enzymes.

[0044] (1) Take the mulberry branch and cut off the mulberry branch bark with a knife, cut off the mulberry branch bark, wash away the sediment with tap water, dry at 100°C for 10 hours, pulverize, pass through a 200-mesh sieve, and obtain the mulberry branch powder;

[0045] (2) Get 100g mulberry branch powder, add 1000g mass concentration and be the ionic liquid [MMIM][DEP] of 70% (w / v%), process 1.5h under the condition of 1000 ℃, the treatment power of microwave treatment is 850w, treat After 65 seconds, add 1L of water to the system to precipitate the mulberry branch powder, wash with water 2 to 3 times to remove the ionic liquid (the aqueous solution of the ionic liquid can be distilled to remove water to a certain concentration and can be reused), and place it in a blast drying oven at 75°C in until dry to obtain the initial sample;

[0046] (3) Put the initial sample obtained in step (2) into a crucible, place i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com