Purification method of NN dimethyl acetamide

The technology of a dimethylacetamide and a purification method is applied in the field of purification of NN dimethylacetamide, can solve the problem that NN-dimethylacetamide cannot be used for the detection of residual solvent of nadolamine, and achieves high purity, The effect of increasing the number of plates and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

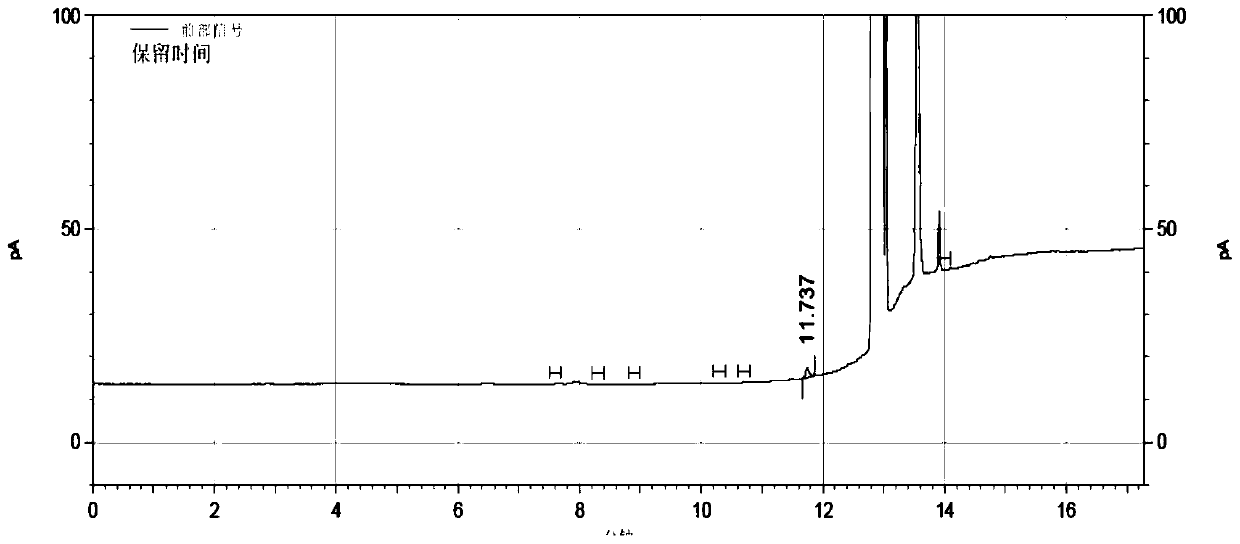

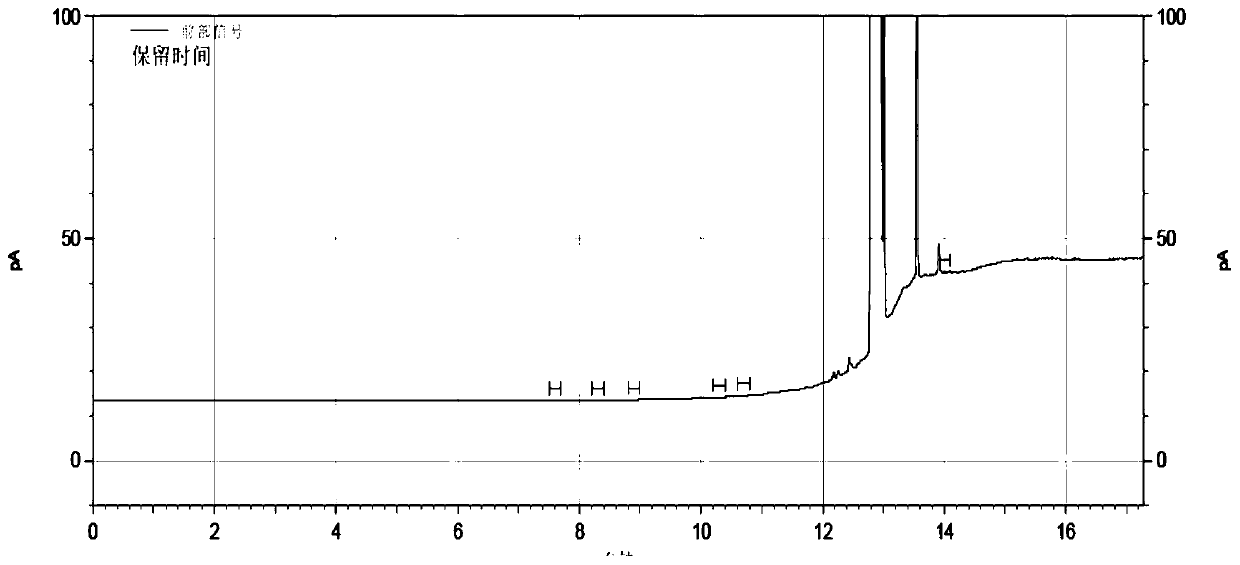

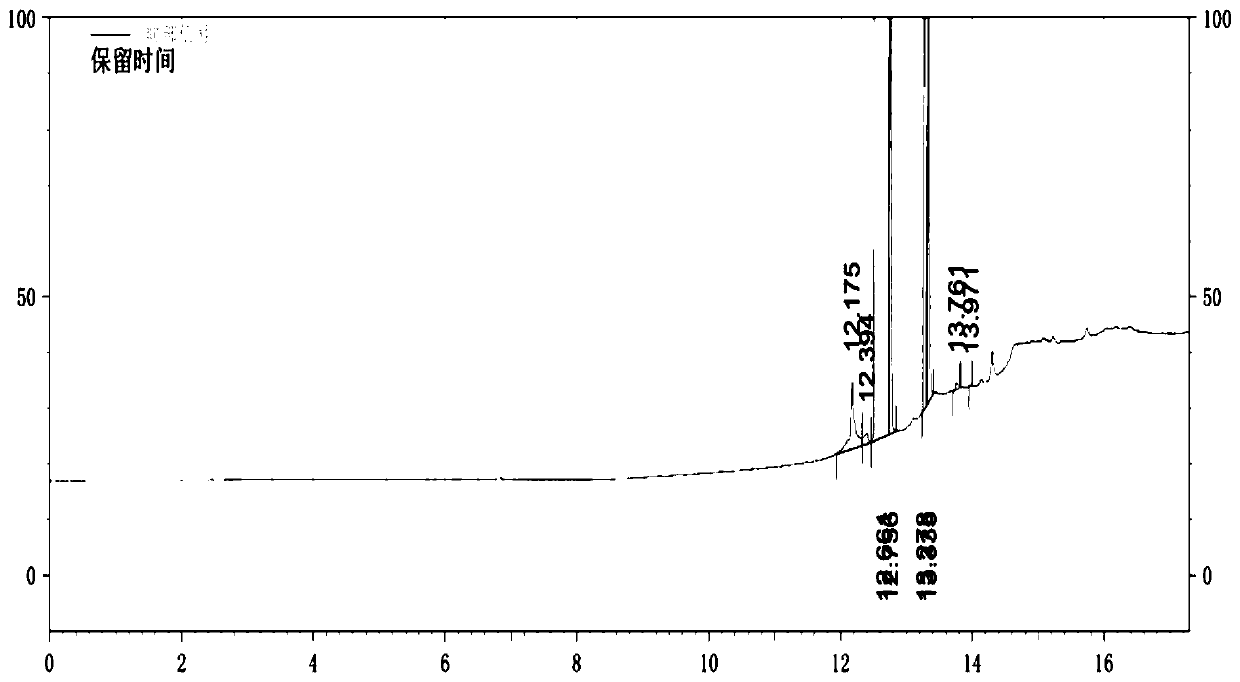

Image

Examples

Embodiment 1

[0032] A purification method of NN-dimethylacetamide, comprising the following steps:

[0033] (1) The round-bottomed flask equipped with 2L industrial grade NN-dimethylacetamide is connected to a condenser connected to a water circulation vacuum pump, placed in an electric heating mantle, and the other end of the condenser is connected to the collection device through a packed column;

[0034] (2) Set the ultra-high temperature of the electric heating jacket to 200°C;

[0035] (3) Turn on the power supply of the water circulation vacuum pump, control the vacuum degree to be -0.080, and keep the boiling temperature of NN-dimethylacetamide in the container at 115°C;

[0036] (4) When there is liquid dripping in the condenser, perform total reflux for 30 minutes, turn on the power supply of the collection device after the total reflux, and the purified NN-dimethylacetamide can be collected;

[0037] (5) The collection of NN-dimethylacetamide in step (4) is carried out in four s...

Embodiment 2

[0044] A purification method of NN-dimethylacetamide, comprising the following steps:

[0045] (1) The round-bottomed flask equipped with 2L industrial grade NN-dimethylacetamide is connected to a condenser connected to a water circulation vacuum pump, placed in an electric heating mantle, and the other end of the condenser is connected to the collection device through a packed column;

[0046] (2) Set the ultra-high temperature of the electric heating jacket to 200°C;

[0047] (3) Turn on the power supply of the water circulation vacuum pump, control the vacuum degree to be -0.080, and keep the boiling temperature of NN-dimethylacetamide in the container at 120°C;

[0048] (4) When there is liquid dripping in the condenser, perform total reflux for 30 minutes, turn on the power supply of the collection device after the total reflux, and the purified NN-dimethylacetamide can be collected;

[0049] (5) The collection of NN-dimethylacetamide in step (4) is carried out in four s...

Embodiment 3

[0056] A purification method of NN-dimethylacetamide, comprising the following steps:

[0057] (1) The round-bottomed flask equipped with 2L industrial grade NN-dimethylacetamide is connected to a condenser connected to a water circulation vacuum pump, placed in an electric heating mantle, and the other end of the condenser is connected to the collection device through a packed column;

[0058] (2) Set the ultra-high temperature of the electric heating jacket to 200°C;

[0059] (3) Turn on the power supply of the water circulation vacuum pump, control the vacuum degree to be -0.080, and keep the boiling temperature of NN-dimethylacetamide in the container at 125°C;

[0060] (4) When there is liquid dripping in the condenser, perform total reflux for 30 minutes, turn on the power supply of the collection device after the total reflux, and the purified NN-dimethylacetamide can be collected;

[0061] (5) The collection of NN-dimethylacetamide in step (4) is carried out in four s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com