Plastic tap and mould and process for its production

A faucet and plastic technology, which is applied in the field of faucets, can solve the problems of difficult mold removal and affecting product yield, and achieve the effect of firm connection, light weight and good implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This plastic faucet is made according to the following process:

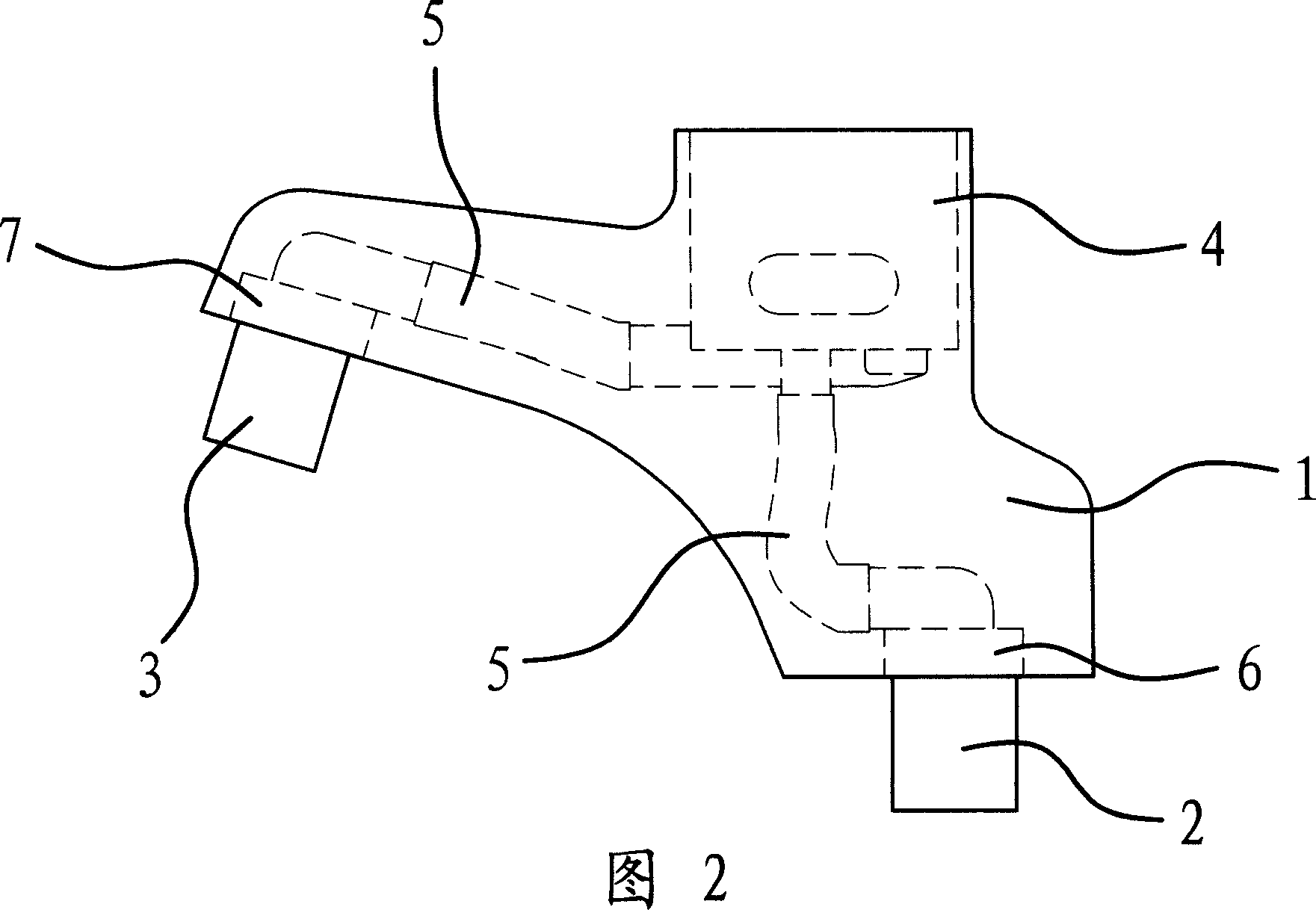

[0060] A. Parts production: make plastic faucet parts, including connecting pipe 5, water inlet seat 6, water outlet seat 7, valve core seat 4, water inlet pipe 2, water outlet pipe 3, valve core, valve stem and handle. Wherein spool seat 4, water inlet pipe 2, water outlet pipe 3, spool, valve stem and handle are common parts, can adopt common processing technology to make, also can directly buy in the market.

[0061] The blanks of the water inlet seat 6 and the water outlet seat 6 with basic shapes are made by casting or directly machining, and then the above-mentioned blanks are processed by turning, wherein the thread turning tool is used on the water inlet seat 6 and the water outlet seat 7 Process the internal thread, thereby manufacturing the water inlet seat 6 and the water outlet seat 7. Select a pipe with an appropriate pipe diameter, and cut several pipe sections that meet the length, so as t...

Embodiment 2

[0071] In this embodiment, the curing time of the plastic in Step E is 11 minutes, and the others are the same as in Embodiment 1.

Embodiment 3

[0073] In this embodiment, the curing time of the plastic in Step E is 20 minutes, and the others are the same as in Embodiment 1.

[0074] The present invention also provides a mold used in the process of manufacturing a plastic faucet, the mold is composed of an upper mold body 8 and a lower mold body 9, the upper mold body 8 and the lower mold body 9 have a concave mold cavity 10 inside, the mold There is also an inlet 17 on the top. In this embodiment, the material inlet 17 is composed of an upper groove 8b located on the upper mold body 8 and a lower groove 9c located on the lower mold body 9. After the upper and lower mold bodies 8 and 9 are covered, the upper groove 8b and the lower mold body The groove 9c forms a material inlet 17 whose size gradually decreases from the outside to the inside, as shown in FIGS. 6 to 12 .

[0075] The upper mold body 8 and the lower mold body 9 are provided with positioning holes that penetrate to the mold cavity 10. The positioning hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com