Two-rolling bearing type pumping rod centralizer

A technology of rolling bearings and centralizers, which is applied to drill pipes, drilling equipment, earthwork drilling, etc., and can solve the problems of poor wear resistance and low fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

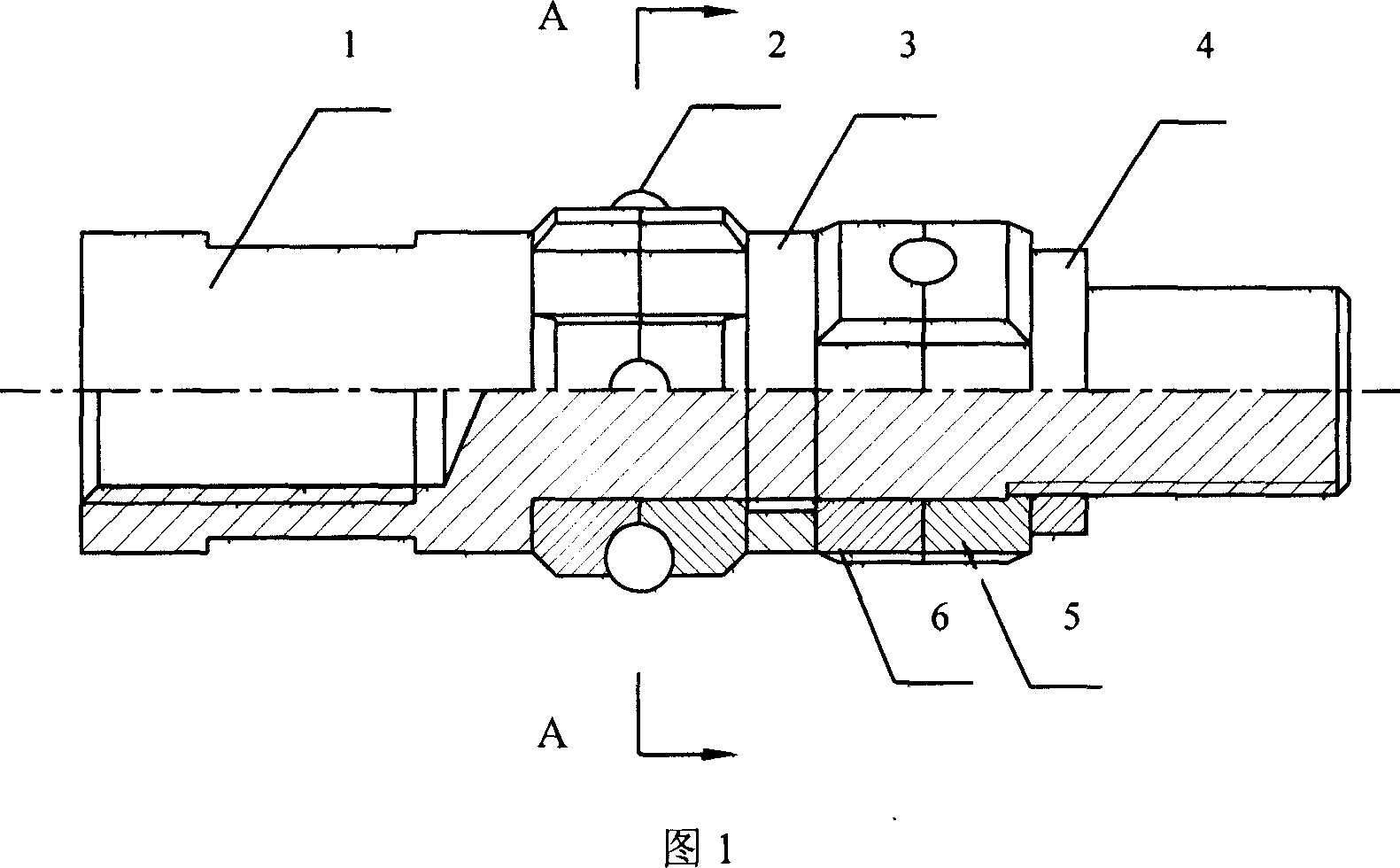

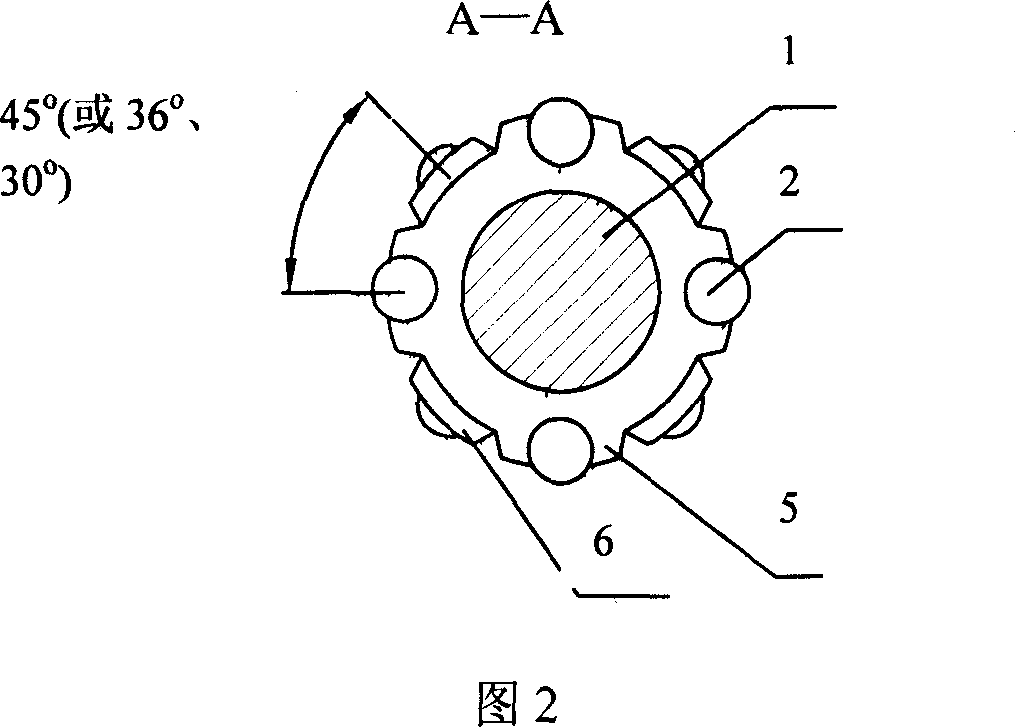

[0007] The embodiment of the present invention is described in detail below in conjunction with accompanying drawing: two righting covers adopt segmented structure, are made up of righting cover sub-block 1 (5) and righting cover sub-block 2 (6). The rolling balls (2) are positioned in the holes formed by the docking of the centralizing sleeve sub-blocks 1 (5) and 2 (6), and are arranged in a regular polygon. Two centralizing sleeves composed of blocks (5) and (6) and a limit ring (3) are fixed on the centralizer rod body (1) through the fastening ring (4). The two centralizing sleeves are arranged staggeredly along the axis of the centralizer rod (1), if the rolling balls are arranged in a regular quadrilateral (or pentagon, hexagonal) shape, the angle between the two centralizing sleeves and the rolling balls (2) is 45°( or 36°, 30°). The centralizer rod body (1) is connected with the sucker rods at both ends through threads. During the working process, the crude oil rises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com