Mesoporous molecular sieve carried olefin polymerization catalyst, preparation method and application thereof

A mesoporous molecular sieve and olefin polymerization technology, applied in the production of bulk chemicals, etc., can solve the problems of detonation polymerization, difficulty in controlling the polymer shape, sticking to the kettle, etc., and achieve the effect of high molecular weight, high melting point, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

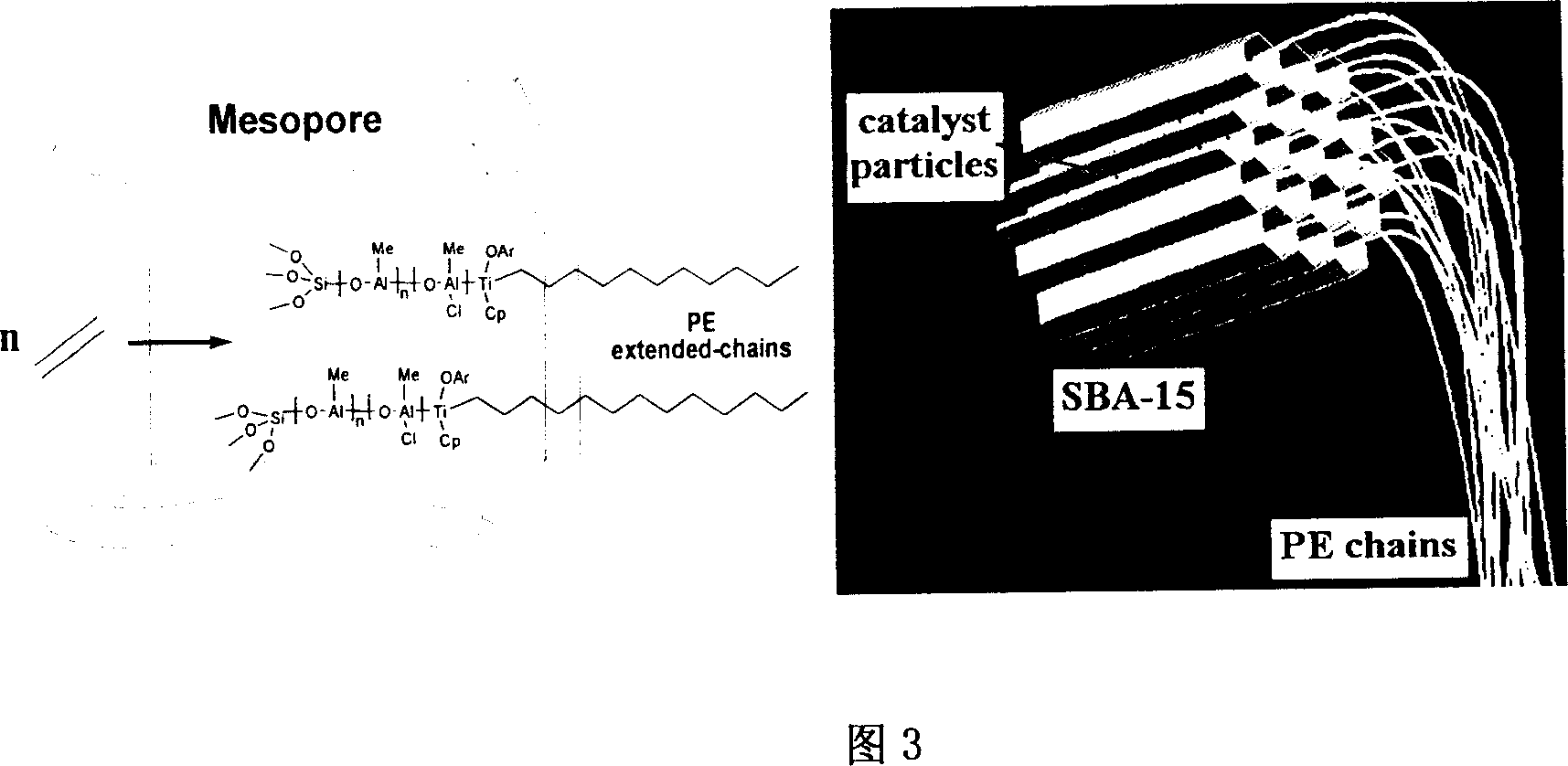

[0029] The preparation of embodiment 1 transition metal Ti (IV) semi-sandwich locene compound homogeneous catalyst:

[0030] -78°C, add 40ml ether solvent to the ligand 5mmol 4-methyl-2,6-di-tert-butylphenolate and 5mmol titanocene solid mixture, stir slowly to room temperature, react for 8 hours and filter , and dry the solvent in vacuo. The residue was dissolved in a small amount of CH 2 Cl 2 Add a small amount of ether or n-hexane to the upper layer, and refrigerate at -30°C to obtain red microcrystalline CpTi(OAr)Cl 2 (Ar=4-Me-2,6- t Bu 2 C 6 h 2 ), yield 83%.

Embodiment 2

[0031] The preparation of embodiment 2 transition metal Zr (IV semi-sandwich locene compound homogeneous catalysts:

[0032] -78°C, slowly add 5 mmol of 4-methyl-2,6-di-tert-butylphenolate toluene solution of the ligand dropwise into 5 mmol of trichloro-zirconocene n-hexane suspension, and slowly warm up to room temperature while stirring , filtered after 12 hours of reaction, and vacuum-dried the solvent. The residue was extracted with a large amount of n-hexane, concentrated, and refrigerated at -30°C to obtain yellow microcrystalline CpZr(OAr)Cl 2 (Ar=4-Me-2,6- t Bu 2 C 6 h 2 ), yield 78%.

Embodiment 3

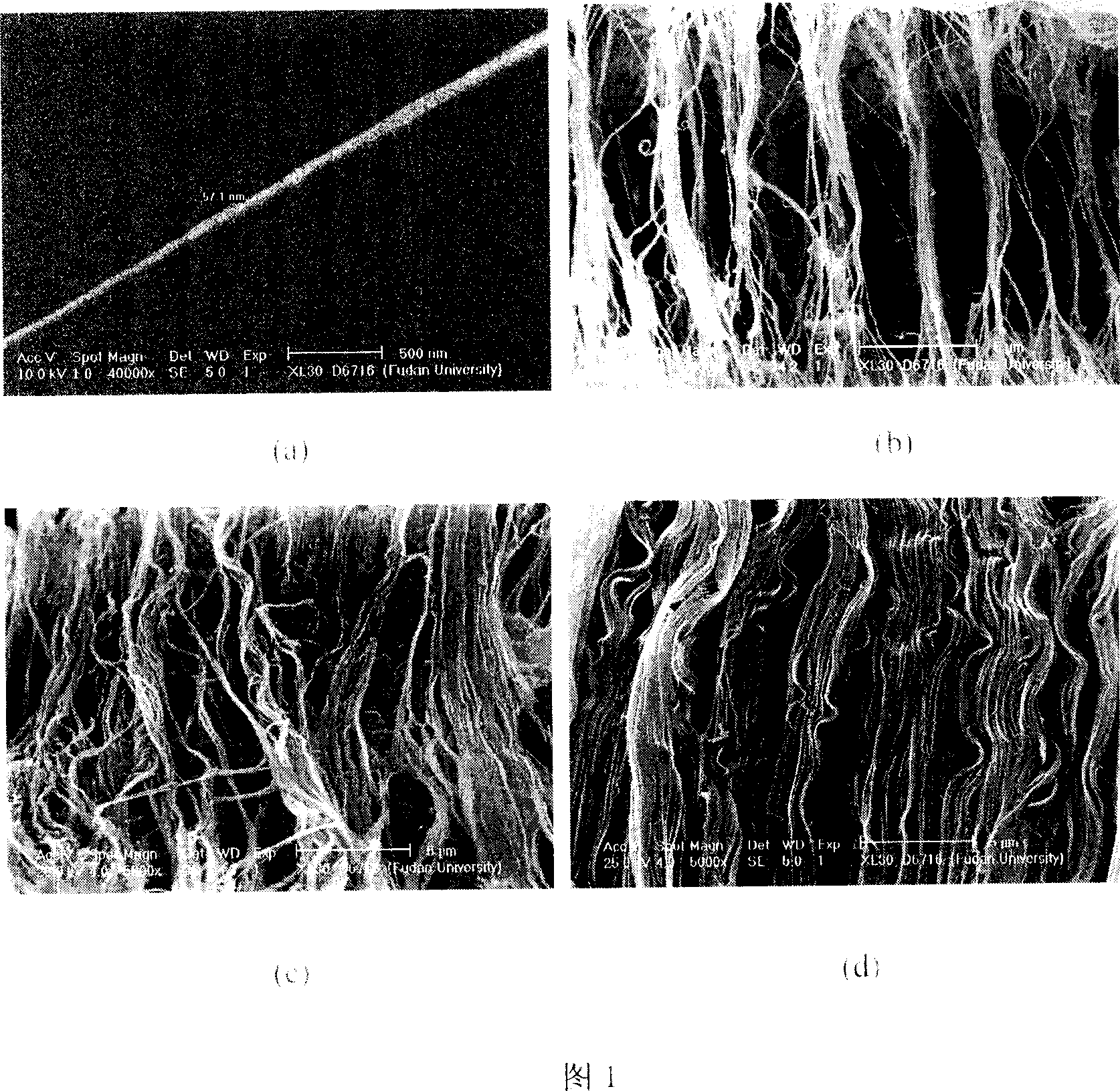

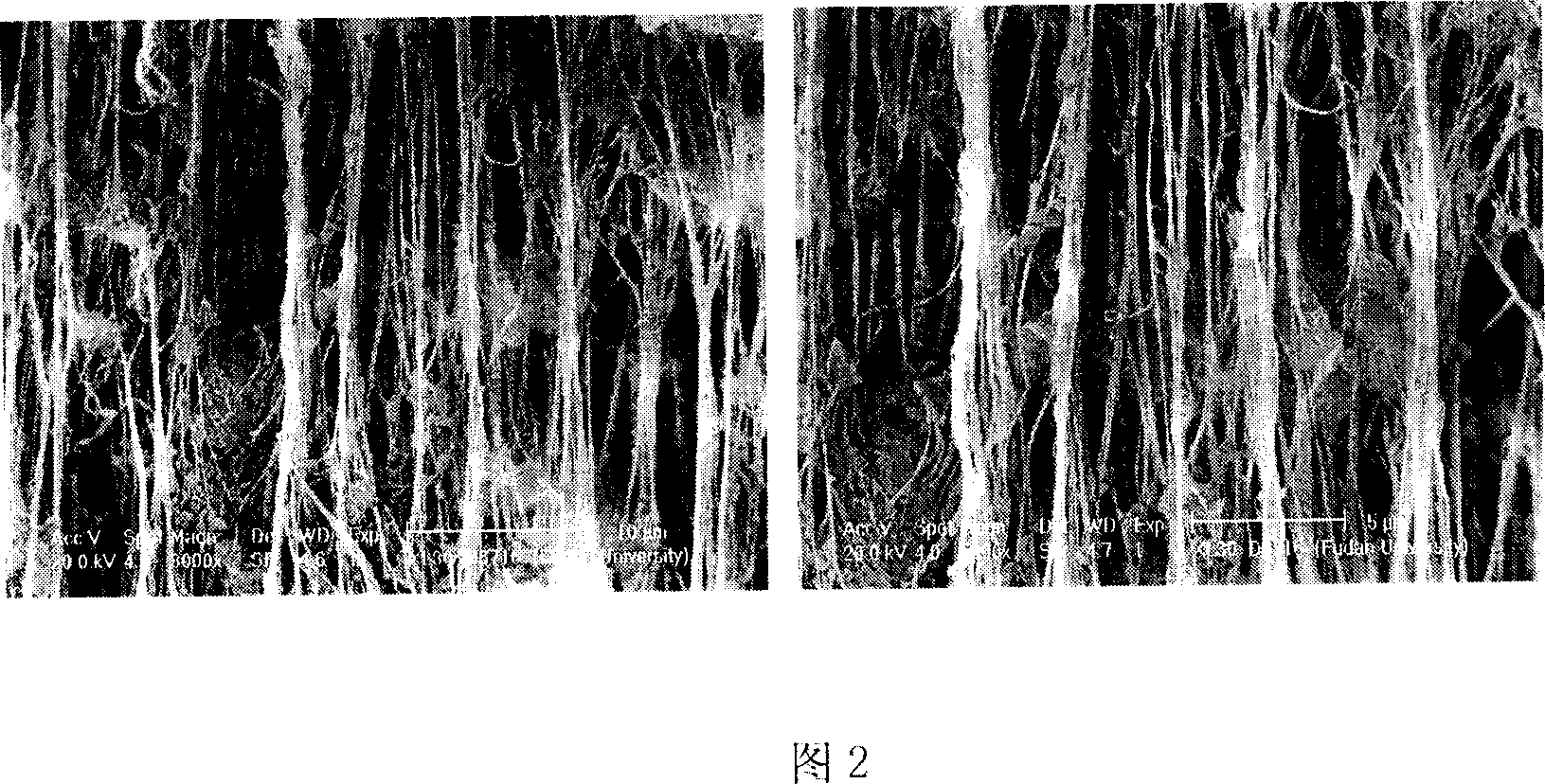

[0033] Preparation of embodiment 3 supported olefin polymerization catalyst:

[0034]Weigh 3.0 g of mesoporous molecular sieve SBA-150, and keep it under vacuum for 8 to 10 hours at 150 to 180 °C; after cooling to room temperature, add 20 mL of toluene; then add 10 mL of MAO, stir at room temperature for 20 h, filter, wash the solid with toluene three times, and then Mix with a toluene solution containing 0.052g of homogeneous catalyst titanium (IV); continue to stir for 18 to 20 hours, centrifuge, wash with toluene, and dry in vacuo to obtain the loaded catalyst component A, with a titanium content of 0.364wt %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com