Technology of preparing hydrocarbons produce from methanol by one-step method

A technology for hydrocarbon products and methanol, which is applied in the field of one-step conversion of methanol to produce hydrocarbon products, can solve the problems of large investment, large number of reactors, long process flow, etc., and achieves low investment, short process flow and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

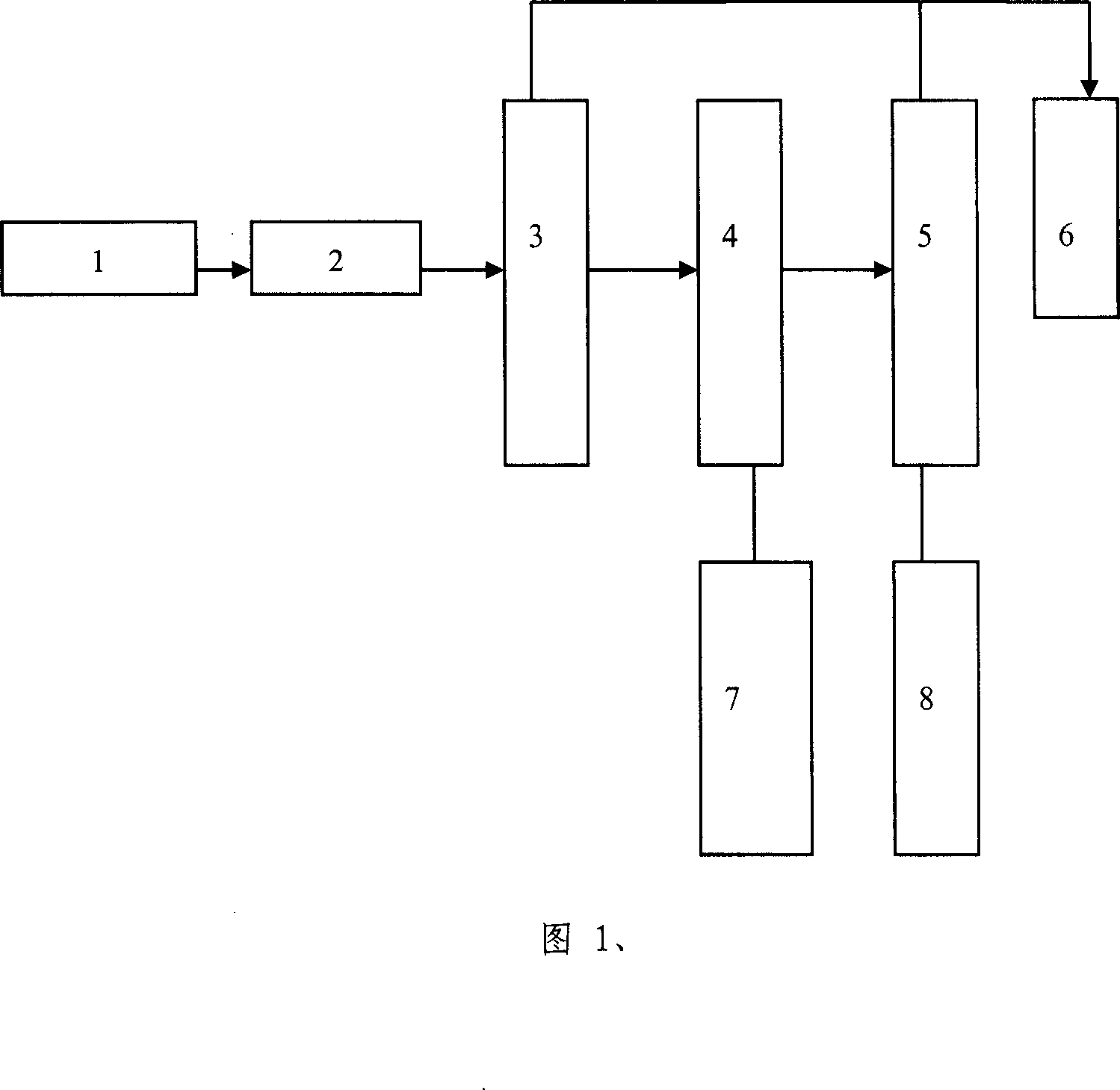

Image

Examples

Embodiment 1

[0041] A. Synthesis of Directing Agents

[0042] The molar ratio composition of the directing agent is SiO 2 : Al 2 o 3 :Na 2 O: n-Butylamine: H 2 SO 4 :H 2 O=40:1:10:28:7.2:2800. The composition of the silicon source is: SiO 2 = 25.13%; Na 2 O = 8.12%; H 2 O=66.75% water glass, first take by weighing 600 grams of water glass, add 126.5 grams of n-butylamine and 1181.3 grams of deionized water to make A solution, put it into the synthesis kettle, under stirring at 300 rpm Stir evenly, then weigh 41.82 grams of aluminum sulfate, put it into a beaker containing 1561.4 grams of water, then add 15.8 grams of sulfuric acid, stir evenly with a glass rod, make B solution, and add it dropwise to the solution in the kettle , Then the still is sealed, continue to stir and start to heat up after 10-20 minutes. In the first step, the temperature is raised from room temperature to 120°C at a rate of 2°C / min for 20 hours, and in the second step, the temperature is raised to 165°C a...

Embodiment 2

[0052] A. Synthesis of Directing Agents

[0053] The raw material composition of the directing agent is SiO 2 : Al 2 o 3 :Na 2 O: 1.6-hexanediamine: H 2 SO 4 :H 2 O=60:1:13:32:3.3:3000. The composition of the silicon source is: SiO 2 = 25.13%; Na 2 O = 8.12%; H 2 O=66.75% water glass, at first take by weighing 600 grams of water glass, add 728.9 grams of deionized water and 149.9 grams of 1,6-hexamethylenediamine to make A solution into the synthesis kettle, at 300 rpm Stir evenly under stirring, then weigh 17.93 grams of aluminum nitrate, put it into a beaker with 1561.4 grams of water, then add 15.6 grams of sulfuric acid, stir it with a glass rod to make B solution, add it dropwise to the solution, then the kettle was sealed, and the temperature began to rise after continuing to stir for 10-20 minutes. In the first step, the temperature is raised from room temperature to 120°C at a rate of 2°C / min for 20 hours, and in the second step, the temperature is raised to...

Embodiment 3

[0061] A. Synthesis of Directing Agents

[0062] The raw material composition of the directing agent is SiO 2 : Al 2 o 3 :Na 2 O: Ethylamine: H 2 SO 4 :H 2 O=80:1:15:38:5.2:3800

[0063] The composition of the silicon source is: SiO 2 = 25.13%; Na 2 O = 8.12%; H 2 O=66.75% water glass, first take by weighing 600 grams of water glass, add 84.33 grams of ethylamine and 1181.3 grams of deionized water to make A solution, put it into a synthesis kettle, and stir evenly under stirring at 300 rpm , then weigh 41.82 grams of aluminum sulfate, put it into a beaker with 1561.4 grams of water, then add 15.8 grams of sulfuric acid, stir it with a glass rod to make B solution, add it dropwise to the solution in the kettle, and then The kettle was sealed, and the stirring was continued for 10-20 minutes, and then the temperature began to rise. In the first step, the temperature is raised from room temperature to 120°C at a rate of 2°C / min for 20 hours, and in the second step, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com