Method for preparing radial glass packaged thermosensitive resistor

A glass encapsulation, thermistor technology, applied in the manufacture of encapsulated/cased resistors, resistors, non-adjustable metal resistors, etc., can solve the problems of low production efficiency, large quality fluctuations, poor consistency, etc., to achieve production efficiency High, good quality and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

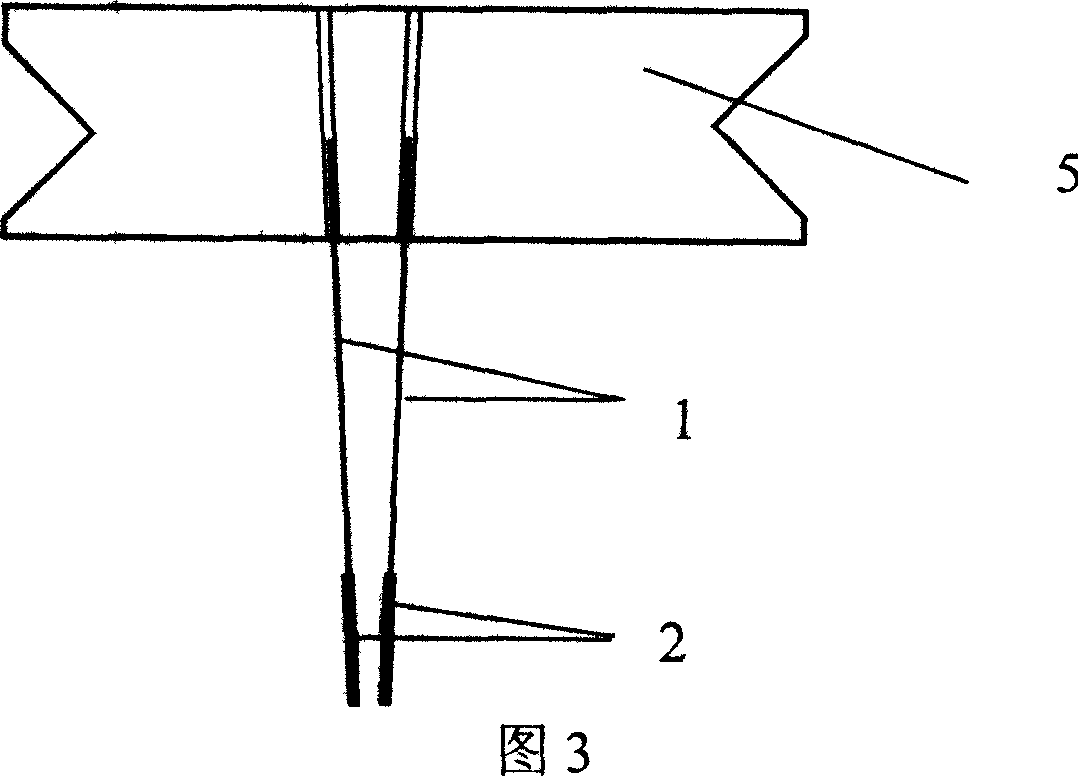

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

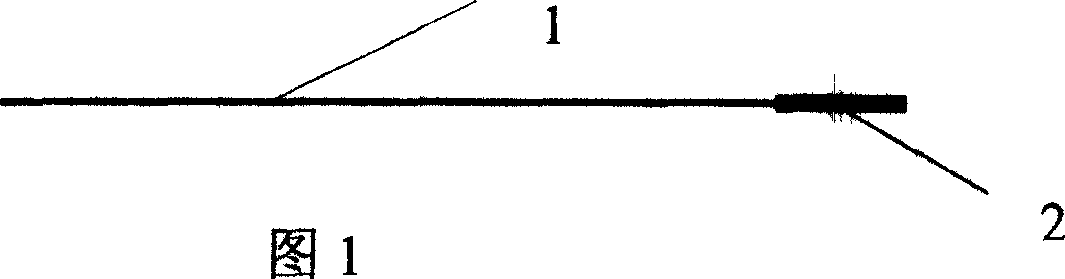

[0018] As shown in Figure 1, the straightened Dumet silk 1 and the silver layer 2 of Dumet silk are selected to be ф0.15-ф0.5mm, and automatic straightening, fixed-length and cutting equipment are used for Dumet silk. Straighten and determine the length, print silver paste on one end of the Dumet wire, and form a good conductive layer after sintering. First fix the Dumet wire on the fixture, leaving a certain length on the left. Use the mobile jig to move to the fixed jig, and clamp the Dumet, then release the fixed jig. The moving fixture returns, and a certain force is applied in the radial direction, and the fixed fixture is clamped at this time. Set the position of the cutter and cut the Dumet. The mobile clamp is released. Repeat to get Dumets of the same length.

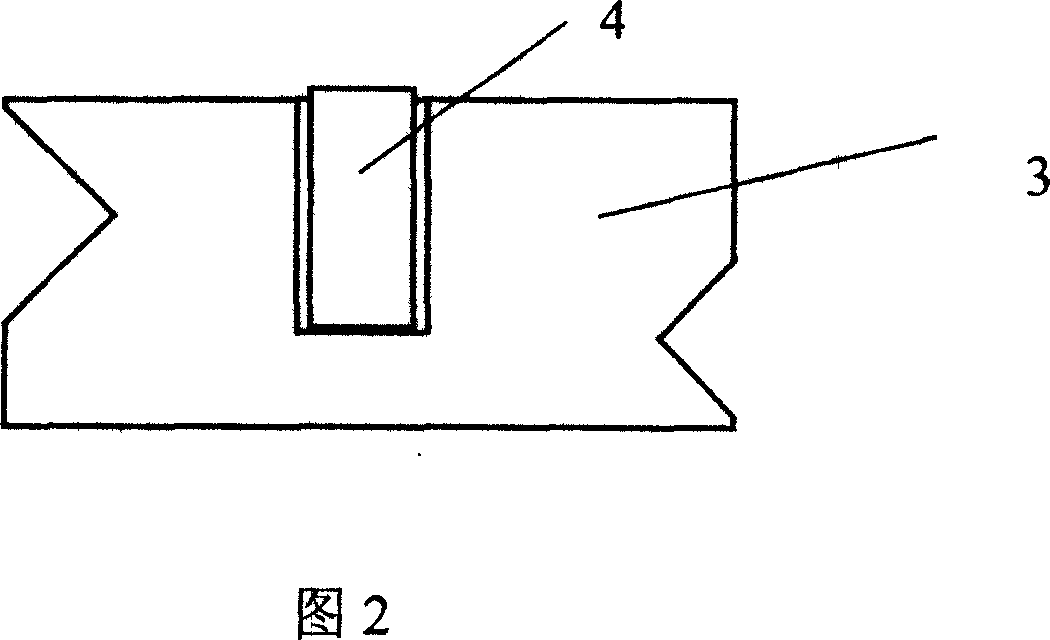

[0019] Arrange the Dumet silk on the mold and clamp it with glue board. The exposed end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com