Single-core inserted optical fiber cold connection extender

A cold connection and plug-in technology, which is applied in the field of single-core plug-in optical fiber cold connection and connection, can solve the problems of overall cost increase, resource waste, and high precision injection molding of mother and daughter, and achieve low manufacturing cost and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

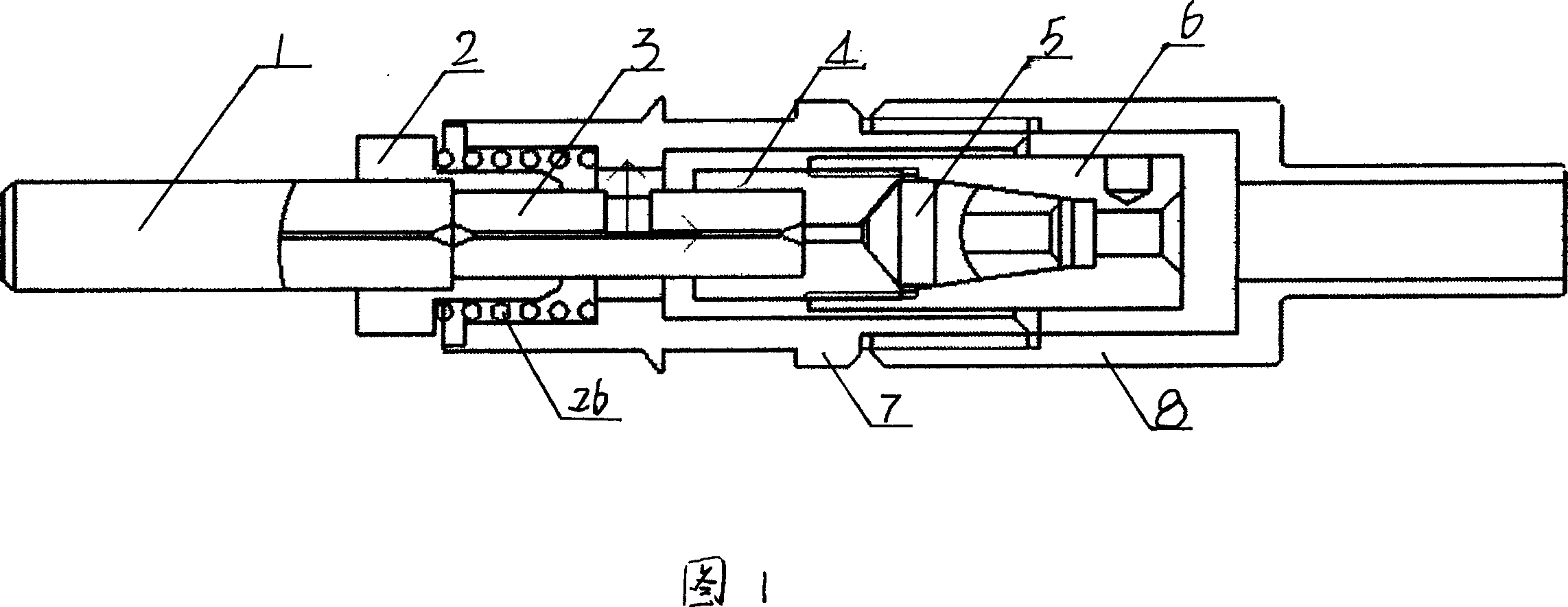

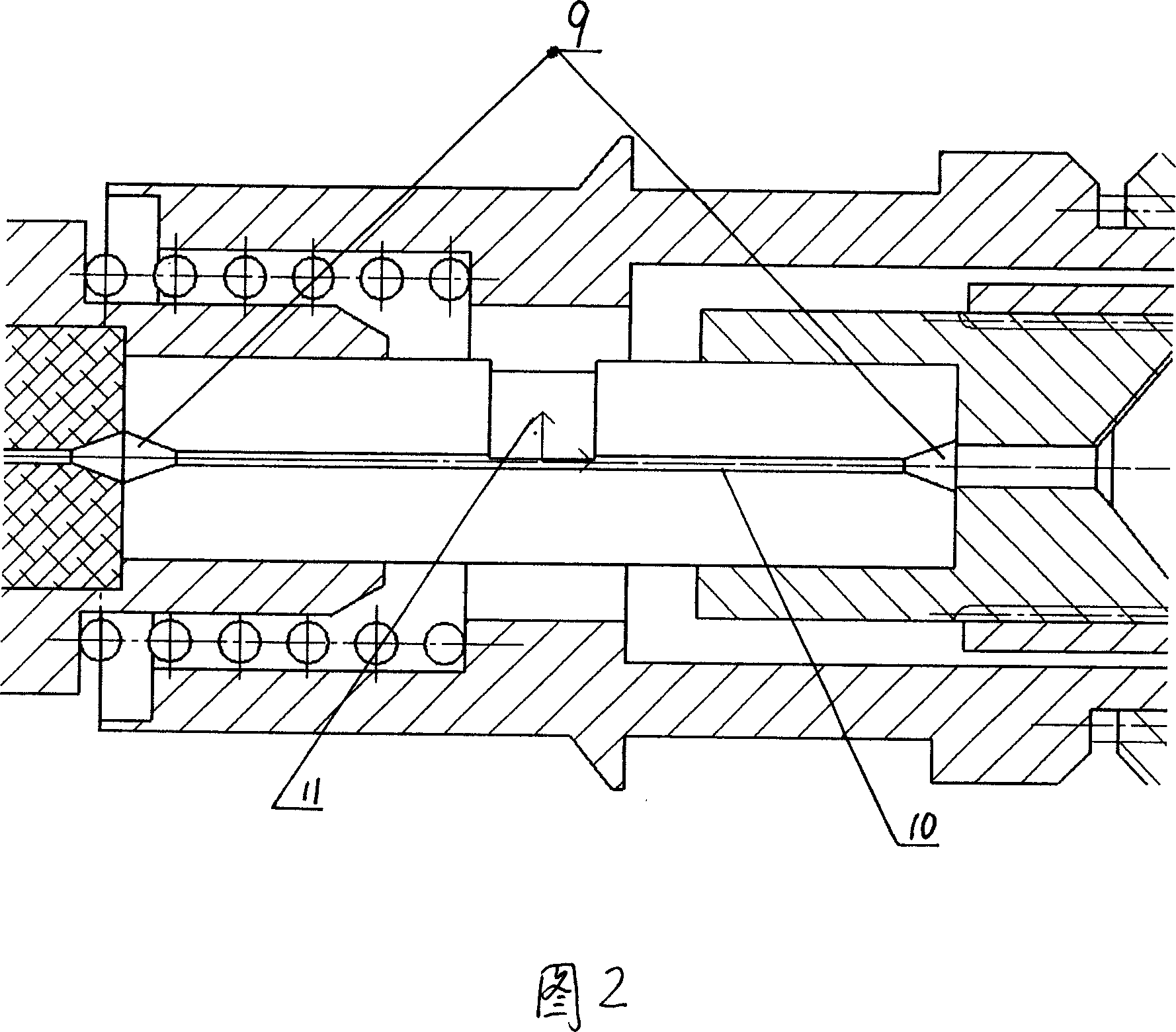

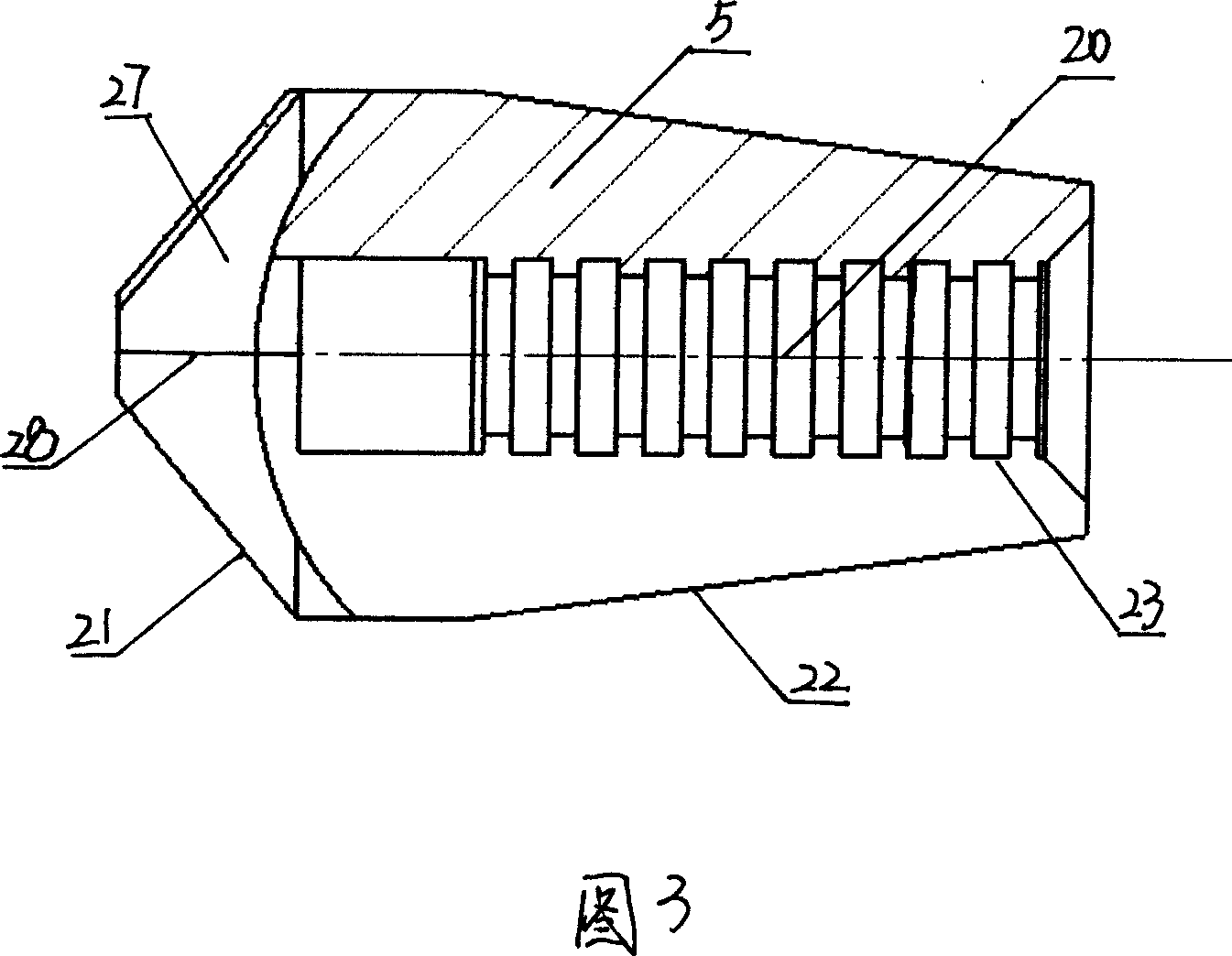

[0017] As shown in Figures 1 and 6, the cavity screw 7 is connected to the cavity nut 8 through the installation nut pair 25 to form an installation cavity 24, and the cold connection splicer body is installed in the installation cavity 24 to form an optical fiber cold connection splice as a whole; The connecting sub-body is mainly composed of a connecting device and a locking device, wherein the connecting device is composed of a pin 1, a connecting body 2, and a positioning body 3, and the pin 1 is connected to the positioning body 3 through a connecting body 2 to form a connecting device, wherein the locking The tightening device is composed of locking screw 4, locking nut 6 and double cone collet 5. The locking screw 4 is connected with the locking nut 6 through the locking nut pair 16 to form a locking cavity 12, and a double cone is installed in the locking cavity 12. The cone chuck 5 forms a locking device; wherein, as shown in Figure 2, the positioning body 3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com